Oktober 2024

HPS Prominently Present at the IAC in Milano

Participating in the International Astronautical Congress, IAC, has developed into a good tradition at HPS over many years. This year, the company will be represented by Ernst K. Pfeiffer, CEO, together with ADEO project manager Mrs. Dorittya Milankowitch from HPS Munich and Horatiu Gheorghe as IAC-contact point for HPS Bucharest with products like secondary structures, thermal hardware and purging equipment. The HPS-team will keep up full presence during all five days of this international event.

Special highlights will be the company presentations; they are going to take place on Friday, 18th, from 10.15 to 10.45 a.m., and also as part of the Company Slam at the booth of the German association BDLI on Tuesday from 13.15 to 13.45 p.m..

Focus of both presentations will be on the product family of the ADEO deorbit sailsystem for automatic disposal of satellites after their end of mission, serving the idea of clean space, sustainability and debris avoidance even from the beginning of the satellite´s journey.

Main products besides ADEO to be asked at our booth: reflector antennas, deployable antennas, large deployable reflector subsystems, mesh, thermal hardware, purging equipment. HPS will warmly welcome there all its customers from both worlds: classic and NewSpace. For a dedicated prearranged business meeting please send a message to Contact@hps-gmbh.com.

Oktober 2024

Innovative BANT-1 reflector antenna from HPS for Reflex: exemplary symbiosis of NewSpace and established space-SME

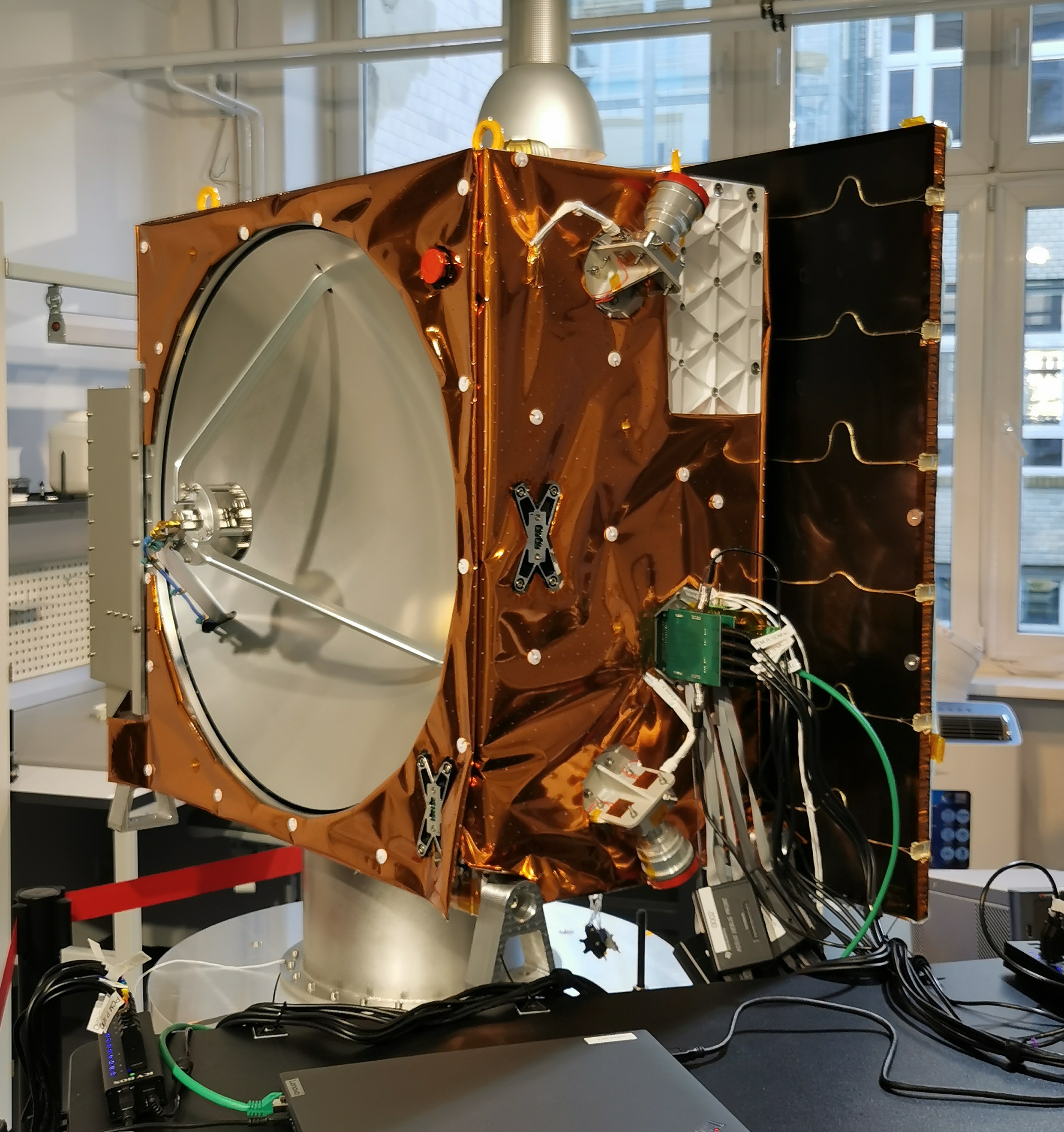

NewSpace – this means, among other things, speed in development, production and provision, paired with innovative versatility as a leitmotif for the performance of the product. A current example of this is the broadband reflector antenna developed for the new Reflex Aerospace satellite by space SME HPS GmbH (Munich, Germany) with a broadband spiral as an axial feed. The primary development goal was to achieve a large bandwidth and considerable gain while at the same time limiting the time from order to delivery to the customer to just 12 months. The antenna consists of a prime focus reflector with a diameter of 700 mm and an f/D ratio of 0.32, which is fed by a compact ultra-wideband cavity-backed spiral (CBS).

HPS thus succeeded in meeting all customer expectations in terms of performance, price, and timing while adhering to best practices and strict quality management; the project can serve as a striking example of an exemplary symbiosis between NewSpace and established space SMEs towards “NextSpace”.

The Reflex satellite will be launched on board a Falcon9 as part of a SpaceX rideshare 12 mission.

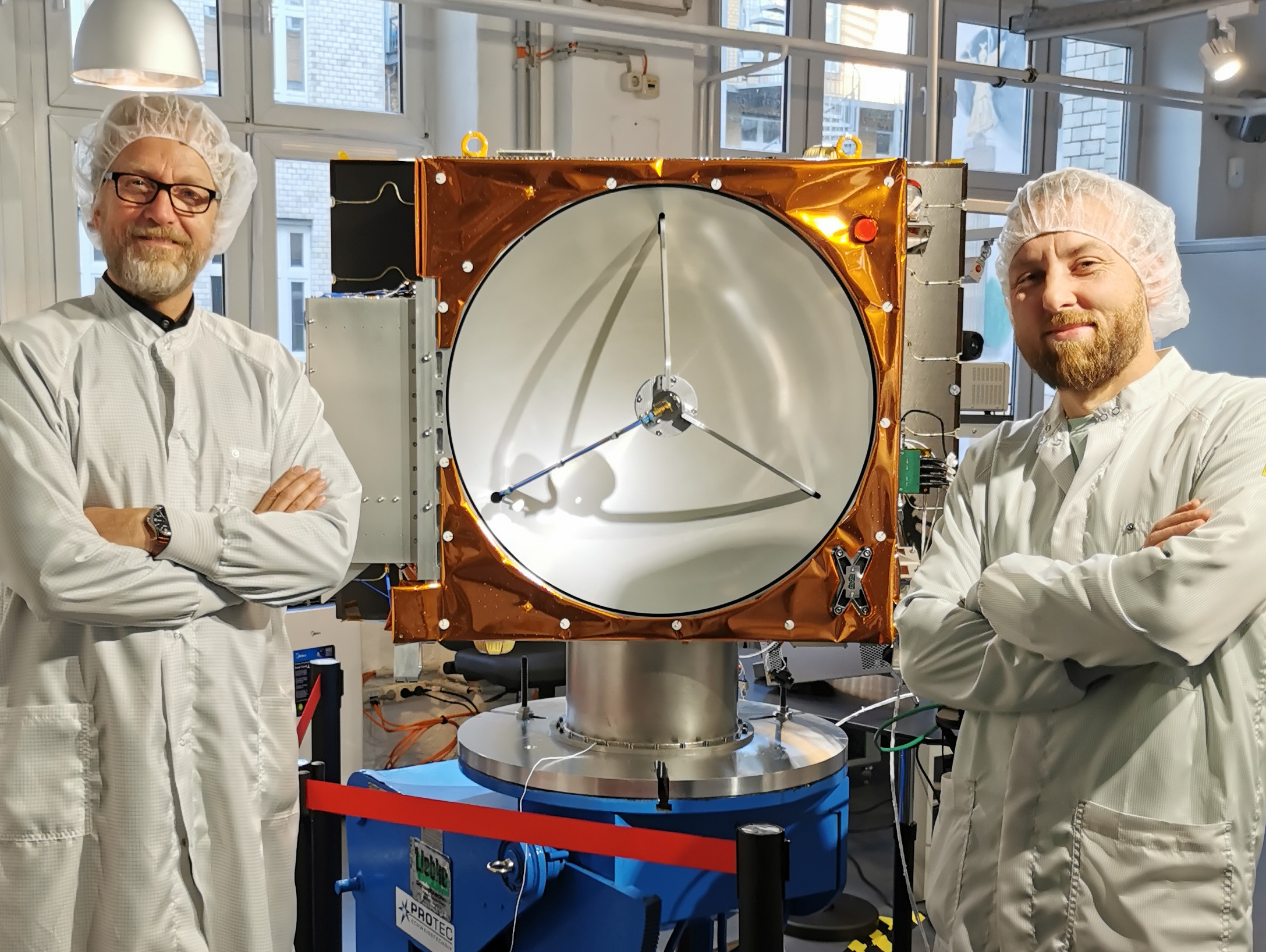

Picture:

Satellite “SIGI” by REFLEX AEROSPACE with integrated reflector Antenna “BANT”, supplied by HPS Munich, ready for transport to the launchpad in the U.S. (left: Ernst K. Pfeiffer, CEO HPS, right:Walter Ballheimer, CEO REFLEX AEROSPACE, visit as of September 30th, 2024)

LEA-X5: New Movie on the completion of the European 5m X-band LDRS

Juli 2021

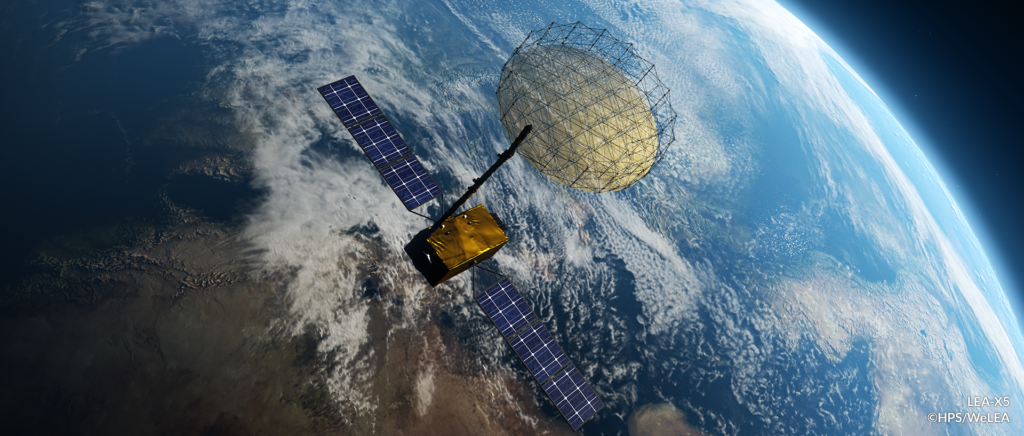

Gladly we announce with a new 20-minutes-movie the completion of the H2020-development „LEA-X5“, the 5m class European Large Deployable Reflector Subsystem (LDRS) operating in X-band.

The film itself is of course showing recent environmental and deployment tests, but it is mainly about PEOPLE, who are space engineers and space enthusiasts, and what they can achieve with combined powers and brains. These people, together with the enablers European Commission and European Space Agency, are making the achievement of „European Non-dependance“ happen.

LEA-X5 is a full LDRS-Subsystem (lead by HPS, Germany) and comprises the

- 5m diameter X-band reflector assembly (lead by LSS, Germany)

- the 5m long deployable arm assembly (lead by HPS, Germany),

- hinges & HDRMs (RUAG, DE),

- deployment electronics (vH&S, DE),

- thermal hardware (HPS/FHP).

Further partners of the H2020-consortium have been: INVENT (DE), FHP (PT), INEGI (PT), TICRA (DK), LUMA (SW), HPTEX (DE), ARQUIMEA(SP), HPS (RO), ETAMAX (DE), WSS (DE), ONERA (FR), TAS (FR), OHB (DE), Airbus (DE).

Most of the consortium members are introduced in the movie, inluding many interviews.

Take your time and enjoy the spirit of doing big things: LEA-X5 – European 5m X-band LDRS Completed (Final Report 06/2021) – YouTube

Best regards,

Your WeLEA-Consortium

March 2021

Europe´s innovative deployable antenna technology takes the next hurdle

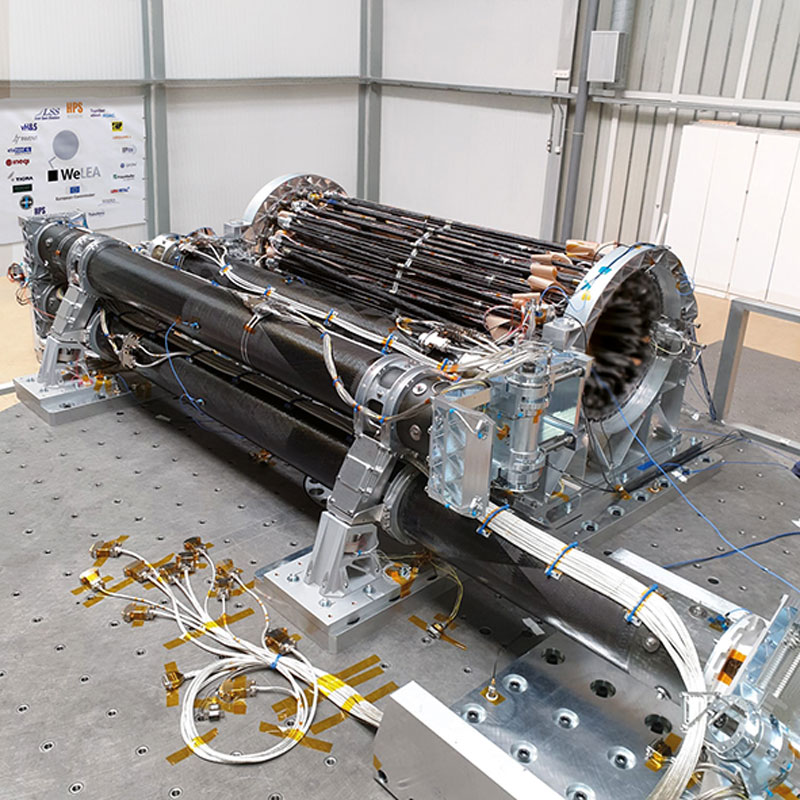

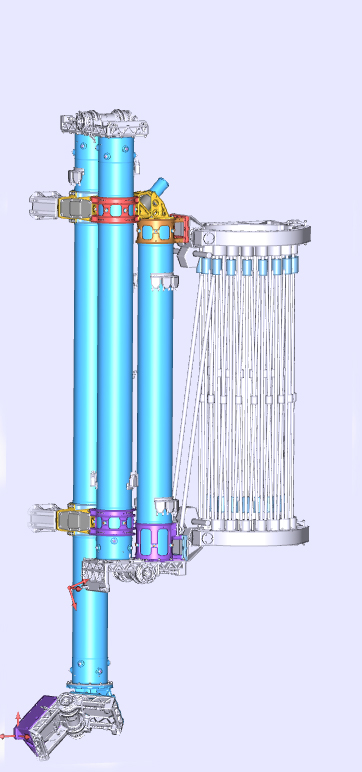

With the successful test of the Deployable Assembly Arm (DAA), which connects a Deployable Reflector Assembly (DRA) to the satellite, just completed at INEGI, the European LEA consortium led by HPS has cleared the next hurdle in the technical realization of Europe’s new antenna technology.

The 5m long DAA consists of 3 hinge mechanisms and 2 HDRMs (both by RUAG Space Germany), Release Mechanisms (by Arquimea, Spain), three CFRP tube segments (by INVENT, Germany), Metal Fittings (partly by HPS Romania), Deployment Control Electronics & EGSE (by von Hoerner & Sulger). Focus of the tests have been the verification of a) the functional full deployment (which takes in total 25 min.), b) a high pointing accuracy of the arm and c) the verification of the mathematical thermo-elastic models.

INEGI (Portugal) is the main partner for the arm deployment test and a good partner of HPS for over 13 years now. INEGI was responsible for the 0-g-simulation Test Stand and the Thermo-elastic Distortion Test Stand. Despite the pandemic and all restrictions the teams could manage this progress with highest motivation and closest possible contact between the INEGI/HPS team on-site in Porto and the HPS-engineers in Germany. HPS is responsible for the DAA and also for the implementation management of the whole LEA-activity. The total LEA-team encompasses 15 partners from 7 countries; the program started in the framework of H2020 in November 2017. The arm deployment test and the TED-test (thermo-elastic distortion) was one of the last tests of this H2020 activity.

The next step – starting still in March – is the environmental test (vibration and thermal vacuum) of the full LDR-Subsystem (Reflector, Arm and HDRM, all connected), which will be performed at INTA in Madrid, Spain.

“LEA-X5” (5m reflector diameter, 5m arm length, X-band application for Earth Observation and Telecommunications) is meanwhile seen as one of the precursing technology developments for the current Copernicus CIMR Mission.

March 2021

Arm and Reflector of LEA-X5 Successfully Mated to Form Complete Subsystem

Fifteen companies – mostly SMEs – from seven countries and one goal: a deployable 5-meter X-band-antenna as a preliminary development for the CIMR project, developed under the European H2020 program (2017-2021). For the first time ever, such a complete subsystem (HPS) has now been successfully assembled in Europe from the reflector- (LSS) and arm- (HPS) assemblies. Previously, the test deployment of the arm and reflector – each individually – had already been successfully passed.

LEA-X5-Subsystem is now at the premises of the consortium´s highly reliable test partner INTA in Spain, where vibration tests for the subsystem are on the agenda in the presence of the LSS- and HPS-teams. In a third round of testing, the subsystem will have to prove itself capable of withstanding the conditions of the thermal chamber.

The next complete subsystem-hardware in this context – the CIMR LDRS-EQM – will be assembled end 2023.

With the key technology behind LEA-X5, the continent is decisively expanding its independence from non-European sources.

October 2012

The vibration and acoustic test campaign has been finished successfully. The reflector is a 1.6m side deployable Ka-band reflector featuring novel technologies and a full CFRP design. It is a collaborative development with Invent (manufacturing) and Technische Universität München (testing technologies and material science) as well as HPS being reflector subsystem responsible, project coordinator and being in charge of design and analyses.

Key tests among other test runs at IABG were:

- sine vibration qualification loads

- random vibration qualifications loads

- acoustic qualifaction loads.

Test to be performed:

- Thermal vacuum cycling.

Key facts of reflector:

- Ka-band

- 1.6m aperture

- GEO application (Tx/Rx)

- full CFRP

- ultra stiff (first eigenfrequency at approx. 130 Hz)

- reflector structural mass approx. 9 kg (even lower mass is possible)

- extremely low thermal-elastic distortions thanks to full CFRP design.

HPS announcing crucial milestone set for Europe´s own large deployable reflector subsystem (LDRS)

April 2019

Large deployable antenna reflectors are among the critical space technologies most urgently needed in Europe in order to drastically reduce the continent´s dependence on goodwill, knowhow, and supplies from the United States. Therefore, back in fall 2017 the EC decided to co-fund in the fame of its Horizon 2020-programm the 7 million € development-project LEA (Large European Antenna) of a consortium with 15 partners out of six European (D, SP, PT, SE, DK, FR) countries under the implementation leadership of HPS, Germany, among them also LSS GmbH (Germany) and RUAG Space Germany. A special cooperation between HPS and Northern Bavarian entities has already led to the development of the central component, the „European Space Mesh“; it will in future be produced in Bavaria. Now the project has taken its crucial milestone when it passed the Critical Design Review (CDR) in April 11-12, 2019, and is heading towards the final stage of its test campaign from February through August 2020. In exchange for the opportunity to gain flight heritage HPS offers the first product, LEA, for free to any customer worldwide.

Major specs of LEA are: deployable reflector aperture at 5.1 meters with a 5.6 meter long deployable arm; a mass of just 100 kilo including reflector, arm, hold-down-and-release-mechanism, harness, thermal hardware, operating frequency: X-band. The stowed volume is as small as 2.6 x 1.2 x 0.6 meters.

This development is not only important in general, but serves also as a baseline for two potentially next Copernicus missions at the horizon with 8 and 12 meter reflector subsystems. The whole development program of LEA is based on precursors undertaken within the framework of ESA technology programs.

For more information on LEA please klick: www.welea.eu.

September 2019

HPS hands over Euclid´s Flight Model of Antenna Reflector Assembly (ARA) to TAS-I in Rome

Euclid, ESA´s ambitious mission to map geometry and development of the Dark Universe over the past 10 billion years from 2022 on has taken a big step forward: HPS delivered the ARA-flight model hardware to ESA´s prime TAS in Rome and the communication subsystem prime TAS in Madrid after all tests (TVT, Bake-out, modal survey, optical check and main reflector contour, grounding and MLI/SLI installation) had been concluded successfully and on time.

Euclid´s ARA (Antenna Reflector Assembly) is one of the mission´s hardware keys, since it is responsible for transmitting all the scientific data, which will provide an unprecedented insight into the origin of the Universe. Extremely lightweight and stable materials have been employed in the just 4.5 kg reflector assembly to assure the demanding strength and performance requirements from the launch phase until the operations at the second Lagrangian point L2, located at 1.5 million kilometers from Earth. The high end precision in the micrometer range has been achieved in the single parts positioning during the alignment activities, allowing optimal performances in the signal transmission.

The Consortium, led by HPS GmbH (Munich based German SME) has successfully implemented the involvement of several countries across Europe. HPS would like to thank its partners for the outstanding work performed together: Invent GmbH in Germany for composite technology, SERENUM a.s. in Czech Republic for metal parts, AAC GmbH for environmental testing, FHP Ltd. in Portugal for Multi Layer Insulation technology and ONERA in France for radio-frequency characterisation testing.

Already back in 2017, HPS had successfully delivered a first Structural-Thermal Model (STM) of the Euclid ARA as well as an Engineering Qualification Model (EQM) in 2018 for testing and qualification purposes at satellite level. The delivery of the Flight Model now took place end of August 2019.

The customer chain explicitly “appreciates the effort done by HPS to fulfill the schedule dates in this complex period of the summer break and congratulates to all the good results obtained”.

October 2019

A European Declaration of Non-dependence in Space

Dear Friends and Fans of Europe in Space,

in the name of all members of our pan-European WeLEA-consortium we proudly present a video, documenting the successful road of the development of one of the most needed critical technologies in space: the Deployable Large European Antenna (LEA).

Invented, designed, tested and manufactured by more than 15 well known space companies from 7 European countries with a total staff of more than 500 dedicated specialists, representing a truly unique team of SMEs and Midcaps, the LEA-product is now taking shape as nothing less than “A European Declaration of Non-dependence in Space”.

Thanks to the farsighted vision of both powerful institutions responsible for our continent´s future in space, the European Space Agency ESA and the European Commission EC, LEA will become an invaluable technological asset to blaze our own trail towards knowledge and understanding as indispensable prerequisites to making this world a sustainable, better place – for life in diversity, for all citizens on the globe, and for one Europe across all its internal borders.

Within the WeLEA consortium HPS Germany, as prime contractor, is responsible for the project- and technical management of the whole LEA-subsystem, the deployable arm assembly and the reflective metal mesh.