April 2023

All Launch Windows are closing for Satellites Without ADEO or Equivalent Deorbit Tech

After FCC, SpaceX, and ESA now also the three German startups racing for the smaller launchers` pole position in the commercial market made it clear that tickets to space will be available only to satellites prepared to be able to deorbit quickly after service.

The companies made their points recently in statements to the German space magazine “Raumfahrt Concret”.

For more details see: RCI-Newsletter-1-2023.pdf (hps-gmbh.com)

Ernst K. Pfeiffer, CEO of HPS, the German spacetech company that has developed ADEO to become the number 1 deorbit device for spacecrafts on the market, comments: “While we witness many cases of exorbitant differences in opinions when it comes to principles the space industry should follow, it is with great relief that we see this case ruled by unanimous voices echoing the new green spirit of deorbit from everywhere.”

3 – 2 – 1 – Next liftoff for the HPS space sail ADEO-N3 on the satellite carrier ION of the Italian mission provider D-ORBIT

January 2023

3 – 2 – 1 – Next liftoff for the HPS space sail ADEO-N3 on the satellite carrier ION of the Italian mission provider D-ORBIT

Already in the heat of last summer, HPS in Munich was preparing for the third mission of the innovative space brake sail ADEO-N, which unfolds automatically at the end of the mission and drives “its” satellite into the atmosphere to burn up. This technology avoids the formation of new space debris already on the ground and finally makes space missions sustainable.

The ION Satellite Carrier with ADEO-N3 with its sail area of 5sqm has been on board a Falcon 9 since the picture book start on January, 31, 2023 from spaceport Vandenberg, California, now on the way to the target orbit at 270 to 500 km altitude at 53 degrees inclination. Probably by the end of 2023 ADEO-N3 will then, as on previous flights – including one with ION also on Falcon 9 – deploy the braking parachute and remove its ION Satellite Carrier from orbit without leaving any residue many times faster than usual. With the flight heritage accumulated by then, the mature ADEO system heralds a “green” space age. Because at least for European missions or missions from Europe, there will – in all probability – no longer be any more launches without deorbit tech on board: The Green Deal of the EU will then also apply to “clean-green missions” in space.

On the current flight, ADEO-N3 acts as another verification of maturity for HPS. D-Orbit and HPS already captured what will happen high above the earth during a nominal mission as historical testimony on video during the last flight:

https://www.linkedin.com/feed/update/urn:li:activity:7021106640993021952

Video is free for publication

The attached video, recorded directly on site with the on-board camera of the ION satellite of the Italian cooperation partner D-Orbit, provides live proof: with the product of HPS, which is now ready for series production after twelve years of development with great support from ESA, DLR and the Bavarian government, a new era of responsibility in space is beginning. ADEO is manufactured in series by HPS at its sites in Munich and Bucharest, primarily for constellation satellites. ADEO products are available for satellites weighing up to 2,500 kilograms at flight altitudes of up to 800 km. Even higher-flying satellites can be operated with ADEO if they have previously lowered their orbit accordingly using their own propulsion. HPS CEO Ernst K. Pfeiffer: “With ADEO on board, satellites do not become space junk in the first place. And at conditions that are ALWAYS more economical than all other options.”

January 2023

Historical video evidence

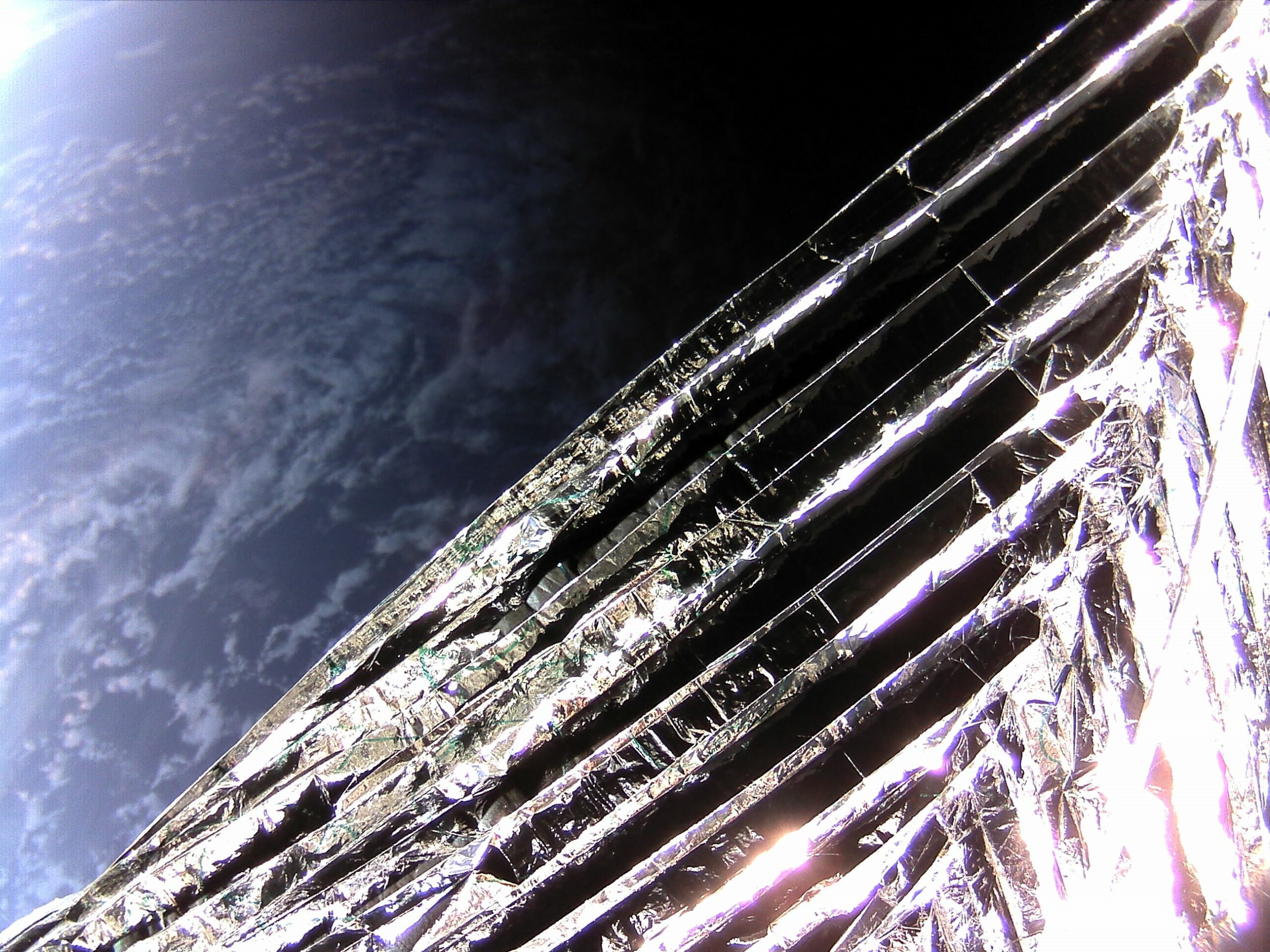

from HPS and D-Orbit

On December 15, 2022, at 12:10 UTC, the world’s unique ADEO braking sail from the German space technology company HPS GmbH, Munich, opened the chapter of sustainability for international spaceflight 500 kilometers above the Earth: as planned, on time and precisely, the sail attached to the ION SCV 003 satellite unfurled over an area of 3.6 square meters to remove “its” satellite from orbit in the shortest possible time without leaving any residue, thus avoiding hazards for other space vehicles and making room for the next generation of satellites at its former orbital position. Preliminary studies and calculations indicate that this will reduce the descent time not by half, as originally expected, but rather by as much as five times.

The attached video, recorded directly on site with the on-board camera of the ION satellite of the Italian cooperation partner D-Orbit, provides live proof: with the product of HPS, which is now ready for series production after twelve years of development with great support from ESA, DLR and the Bavarian government, a new era of responsibility in space is beginning. ADEO is manufactured in series by HPS at its sites in Munich and Bucharest, primarily for constellation satellites. ADEO products are available for satellites weighing up to 2,500 kilograms at flight altitudes of up to 800 km. Even higher-flying satellites can be operated with ADEO if they have previously lowered their orbit accordingly using their own propulsion. HPS CEO Ernst K. Pfeiffer: “With ADEO on board, satellites do not become space junk in the first place. And at conditions that are ALWAYS more economical than all other options.”

December 2022

Qualification success for HPS in space: Smallest version of ADEO braking sail successfully deployed

For 16 months now, an ION satellite carrier of the Italian service provider for unmanned space transportation D-Orbit has been orbiting the Earth in low orbit. Launched by a Falcon 9 on June 30th 2021, it has only one last task after the mission launch of the high-tech passengers from eleven countries: to sail gently as if on “angel wings” to the edge of the Earth’s atmosphere in the shortest possible time with the help of the autonomous braking sail ADEO from the Munich-based space company HPS and to burn up there without leaving any residue.

The test model is the smallest variant of the ADEO product family with a weight of 800 grams, a packing size of 10x10x10 cm and an unfolded sail area of 3.6 square meters. This ADEO-mission “Show me your Wings” is now the final proof-of-concept in a series that also included a first flight with Rocket Lab’s Electron in 2018 and several parabolic flights from 2019 to 2022.

After the end of this nominal ION mission called “Wild Ride”, ADEO’s decelerator sail now deployed in front of the “eyes” of the integrated camera and immediately initiated descent (“deorbit”). ADEO completes deorbiting many years faster than the “unbraked” satellites currently still in widespread use and clears its operational position in orbit correspondingly earlier for a new satellite, which also prevents uncontrolled pollution of space by collision debris. In addition, ADEO helps extend the satellite’s uptime by allowing the sail to continue its descent even when the satellite is out of power and propulsion.

Incidentally, the time required for deorbiting is accurately measured so that it can be used for any necessary recalibration of the HPS deorbit timer. This is a globally unique computational program for predicting the deorbit times of all possible satellites with and without ADEO braking sails. The theoretically developed mathematical algorithms of the computer are thereby differentially refined by empirically obtained data from the field. The ADEO Deorbit Timer is a valuable service to HPS customers around the world.

Series production of the ADEO versions for all satellite classes with flight altitudes below 900 kilometers is in full swing at HPS in Munich (Germany) and Bucharest (Romania). The first companies, such as NewSpace startup Reflex Aerospace (Berlin and Munich), have already signed letters of intent to equip their entire future satellite fleet with ADEO or have announced that they will do so shortly. Others like BST, Berlin, are integrating ADEO as a standard option in their offerings to customers. An additional surge in demand was triggered in the fall of 2022 by the announcement by international policymakers that satellite deorbit times would be drastically shortened down to just 5 years due to the extreme increase in usage density on all orbits, and that corresponding additional equipment would be required by law.

The extremely sharp picture proof of the successful unfolding now opens a new chapter in the history of HPS, in addition HPS CEO Ernst K. Pfeiffer: “And again, a new chapter of programmatic success could be written, which is only possible through trusted space partnerships: research and development with institutes (like the Fraunhofer Institute in Freiburg and the DLR in Bremen) in the early and development stages, financial support from the Bavarian State and the German Space Agency, a vey strong engagement of ESA within its GSTP-program (without this support, including the people behind it, we would still be a long way off!!!), the extremely dedicated staff of my NewSpace team and finally with the people of the system companies, like D-Orbit, who finally, made possible to download from space the image of the unfolded sail, which is important for our next chapter. A great step for HPS, another step for sustainable spaceflight.”

ADEO – Contact: adeo@hps-gmbh.com

May 2022

Exciting new Partnership for Sustainable Use of Space

Paris-Munich-Berlin, September 19th, 2022. Today satellite manufacturer Reflex Aerospace (Munich/Berlin) and space-tech company HPS (Munich), signed a letter of intent that will set the pace in striving for a sustainable use of space, through the prevention of space debris Reflex Aerospace is committed to removing all satellites from orbit after system end of life, and has chosen subsystem specialists HPS as its preferred partner to equip their satellites with ADEO sail-system as the deorbit system. The mission is clear, to ensure a safe and sustainable use of space for the foreseeable future. The two German Space players share a common goal in putting the European Commission´s “Green Deal”, ESA’s “Zero Debris Initiative” and the US “National Orbital Debris Implementation Plan” into practice.

The dragsail ADEO is available in three different versions, and covers all possible shapes and sizes of satellites active on orbital altitudes up to 900 kilometres. As a result, ADEO provides their system to over 90 percent of all constellations that are currently in planning. Partnering with ADEO underlines Reflex’s ambition to foster sustainability in space and responsive space capabilities, creating additional value for their satellites and subsequently for their customers. The first step and first integration of an ADEO dragsail will be the Reflex Demonstration Mission planned for mid 2024.

The CEOs of both companies signed the agreement today, Walter Ballheimer for Reflex, and Dr. Ernst K. Pfeiffer on behalf of HPS. Following the signature, Walter Ballheimer said, “We know the satellite manufacturing business for a long time, and from a mere business perspective one can understand that some of our competitors hesitate to invest in sustainability, if that affects rentability. Our view is, however, that this is short sighted and will inevitably lead to a situation where space endeavours become incredibly risky due to the amount of debris in the low earth orbit We don’t want to wait for this scenario to materialize, instead, we see it as a clear mandate for us and our customers to assume factual and ethical leadership in this matter.” Ernst Pfeiffer added: “Every breakthrough is a highly emotional moment, and this one now is certainly one of the most important ones in the history of our company. We started developing large deployable sail subsystems, originally with partners for the purpose of solar sailing ((i.e. DLR Institutes), back in the year 2000. It took over twenty years, uncountable hours of work done by the best engineers in the field, as well as sweat and tears when the project ran more than once into dangerous waters concerning its long-term financing. We are glad and thankful that over the decades we received so much support from people and institutions who never stopped believing in our final success. DLR and ESA have to be mentioned here in their role as most important strategic investors. This step together with Reflex Aerospace justifies the worthiness of all that effort and shows that ADEO will make its way as the central tool in keeping space save and sustainable.”

For more detailed information on ADEO see: https://www.hps-gmbh.com/en/portfolio/adeo-angel-on-wings/

For more detailed information on Reflex Aerospace see: https://www.reflexaerospace.com/

September 2022

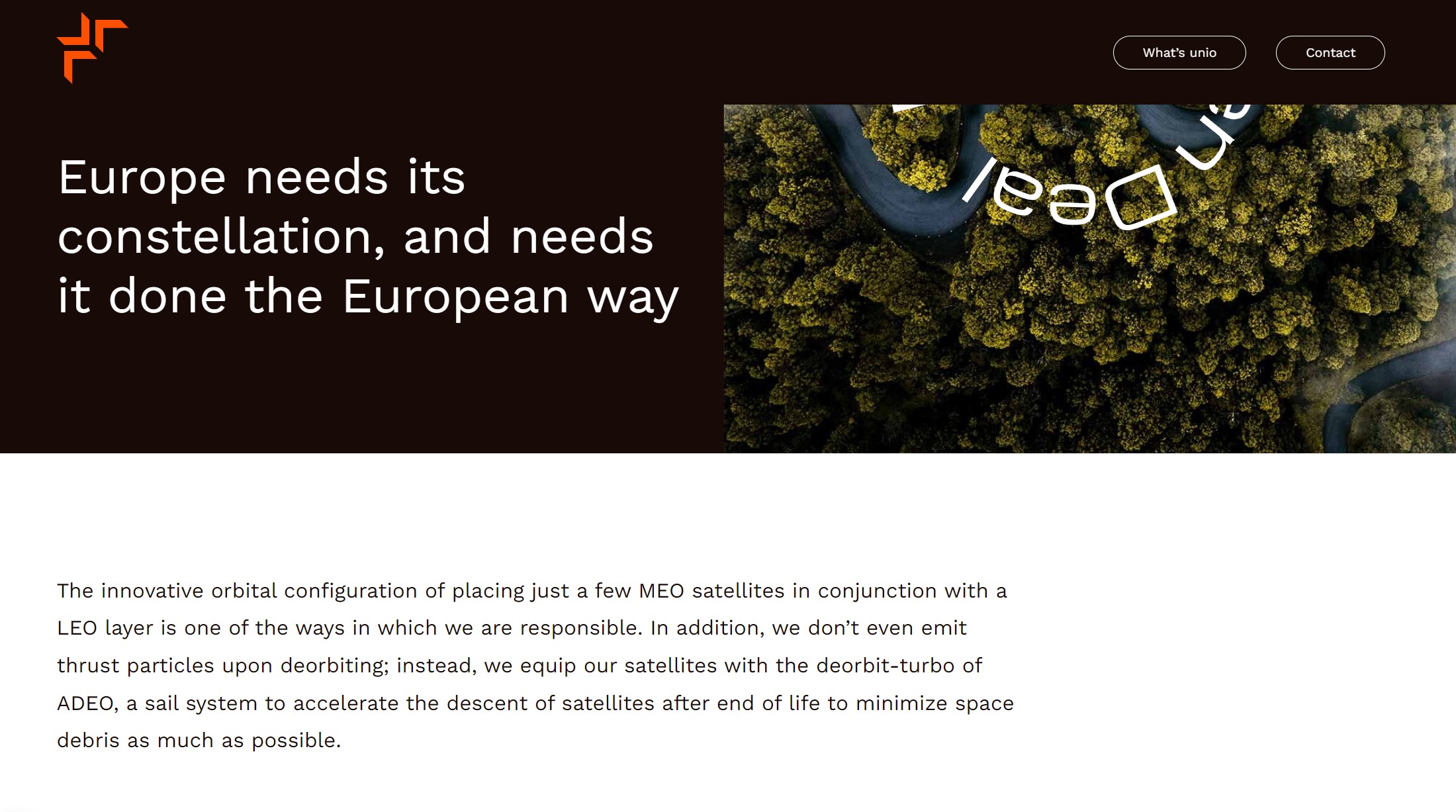

UNIO will equip all their European constellation satellites with ADEO

UNIO Enterprise GmbH, THE European NEWSpace System house for satellite constellations made in Germany, founded by ISAR Aerospace, Mynaric, Reflex Aerospace and SES S.A has confirmed to equip all their European constellation satellites with the ADEO dragsail module: https://unio.global/.

ADEO will accelerate the decommission of the satellites and prevents space from getting polluted by debris even before it occurs.

We feel honored to have been selected as a partner for space sustainability by this meanwhile famous European NewSpace system house: To us at HPS, this is inspiration and motivation to carry on driving the idea of space sustainability to its technological extremes.

August 2022

ADEO deorbit sail product family continues to grow: Successful financing round for industrialization of ADEO Medium for constellation satellites

Paris-Munich. August 1, 2022.

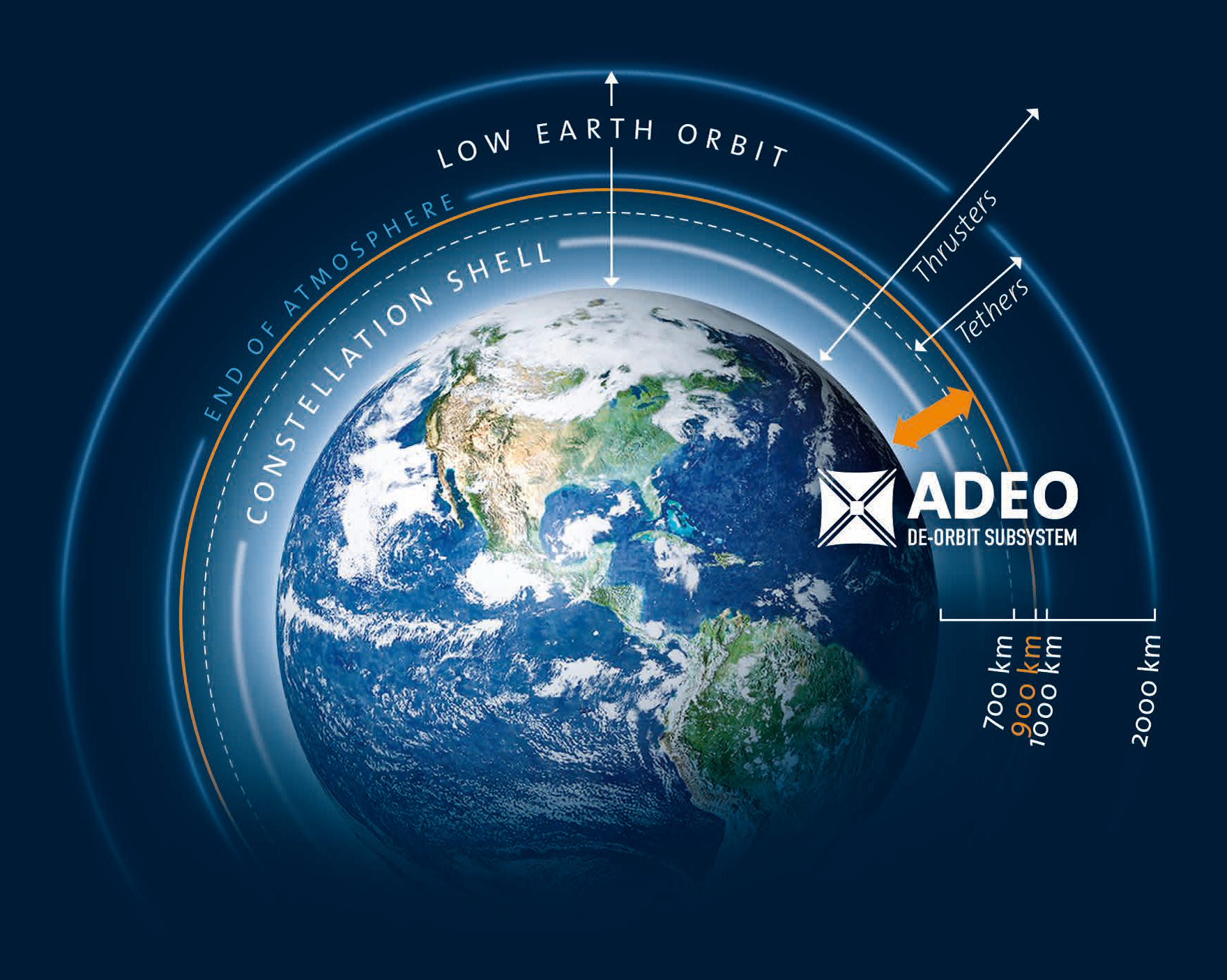

Just one last signature, and the success story of the almost decade-long development of the European deorbit sail ADEO by HPS is going to find its seamless continuation: the model ADEO M for medium satellites of 100-700 kilo weight on orbits up to 900 km altitude – so, typical representatives of the currently almost exponentially growing constellation projects – will be made fit for series production and distribution on the commercial market by the HPS Group in Germany and Romania.

Parallely, additional features of ADEO N (Nano) will be developed. ADEO M follows the versions ADEO N and ADEO L (Large), which have already been on the market for 1.5 years. With the third model, HPS now closes the last gap in its product portfolio and addresses in particular the booming NewSpace market thanks to maturity level TRL 9 and growing flight heritage on missions of various carriers with world-leading deorbit automatic.

This leadership is also a result of the steady and now renewed support from Europe’s GSTP technology program and its German SME initiative on the part of ESA and DLR Space Agency. “Everyone is talking about space debris; thanks also to ESA´s “Zero Debris Initiative”, with ADEO, our customers are making sure it doesn’t even happen.

This is the only way a clean-green mission works, the only way the EU’s Green Deal becomes a reality also in space.”

For each satellite on LEO there is a suitable ADEO, which accelerates deorbiting by a factor of about 20. All interested companies get the exact forecast free of charge and super fast; all they have to do is feed our globally unique “ADEO deorbit timer” with the data of their satellite and then let the algorithms do their jobs,” says HPS CEO Dr. Ernst K. Pfeiffer. As in the case of ADEO N and ADEO L, already now orders for new satellite projects are also being accepted for ADEO M, shortly before the start of series production, in order to harmonize planning and production processes on both the HPS and the customer sides.

July 2022

Flight of ADEO at the end of 2022

At the height of the summer vacations, HPS in Munich is at full power for the preparations for the third mission of the innovative ADEO space braking sail, which deploys automatically at the end of the mission and propels “its” satellite up to 20 times faster to burn in the atmosphere. This avoids pollution and makes space travel sustainable.

It will arrive in Italy as early as the end of August for assembly on the ION Satellite Carrier, D-Orbit’s orbital transfer vehicle (OTV). It is the ADEO-N version for small satellites with a sail area of 5 square meters.

Falcon 9 from SpaceX will be responsible for the transport into a mid-inclination orbit towards the end of 2022. With the flight heritage accumulated by the end of the year, ADEO will enter a new space age in 2023.

At least for European missions or missions from Europe, there will most likely be no more launches without deorbit technology on board:

The EU’s Green Deal then also applies to clean-green missions in space.

June 2022

Breaking News: ADEO dragsail by HPS as standard deorbit device for “Reflex Aerospace satellites”

Next milestone in commercializing ADEO dragsail for deorbit:

Reflex Aerospace (supplier of tailor made, high performance small satellite platforms) announces to use the automatic ADEO dragsail by HPS as standard deorbit device for their satellites. ADEO will guarantee a maximum deorbiting time of less than 5 years and contribute to Reflex Aerospace´s philosophy of responsible, sustainable and future-oriented space missions. Together we realize CleanGreen Space missions!

December 2021

World premiere: Deorbit-Turbosail „ADEO“ by HPS has been selected to safeguard sustainability of Europe´s own constellation

By 2025, Europe will have its own constellation of satellites to ensure sovereign capacity for both commercial and institutional communication channels. Fast Internet, autonomous mobility at sea, on ground and in the air, automatic exchange of information between technical installations, support for military and humanitarian actions, and other applications for public authorities, companies, and citizens realised by a consortium formed by Reflex, laser specialist Mynaric and launch service provider Isar Aerospace.

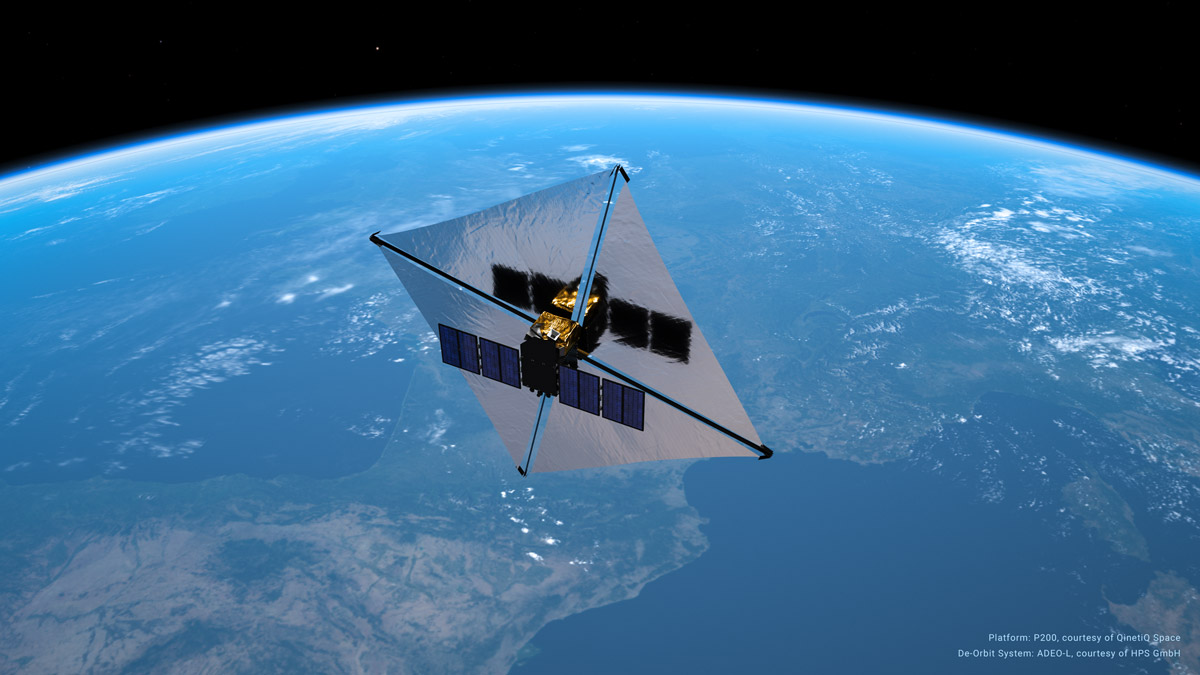

The European Commission is also very interested in such a concentration of innovative forces and selected the UN:IO consortium for one of its two study tenders addressed to companies from the so-called “New Space” domain and endowed with 1.4 million euros. For the EU, a secure, very fast and, above all, sovereign communications network for Europe is a top priority. In addition, it must meet sustainability criteria for the EU’s “Green Deal” – and that is where ADEO comes in: The ADEO subsystem is a scalable, deployable drag augmentation device that uses the residual Earth atmosphere present in Low Earth Orbit (LEO) to passively de-orbit satellites between 1 to 1.500 kg. For the de-orbit manoeuvre, a large surface is deployed which multiplies the drag effect of the satellite´s surface significantly: The drag force is increased causing accelerated decay in orbit altitude. Advantageous about a drag augmentation device is that it does not require any active steering and can be designed for passive attitude stabilization, thereby making it also applicable for non-operational, tumbling spacecrafts. The passive ADEO subsystem requires neither extra propulsion nor engine, which makes it lighter in comparison to active subsystems.

So, after years of development, tests and zero-g- and in-orbit-verifications ADEO is now going to celebrate its world premiere as central element bringing sustainability to space on angel wings.