Cubesat-UDAN: CDR successfully completed – a major milestone for Europe’s disruptive antenna technology

Cubesat-UDAN by HPS: CDR successfully completed – a major milestone for Europe’s disruptive antenna technology

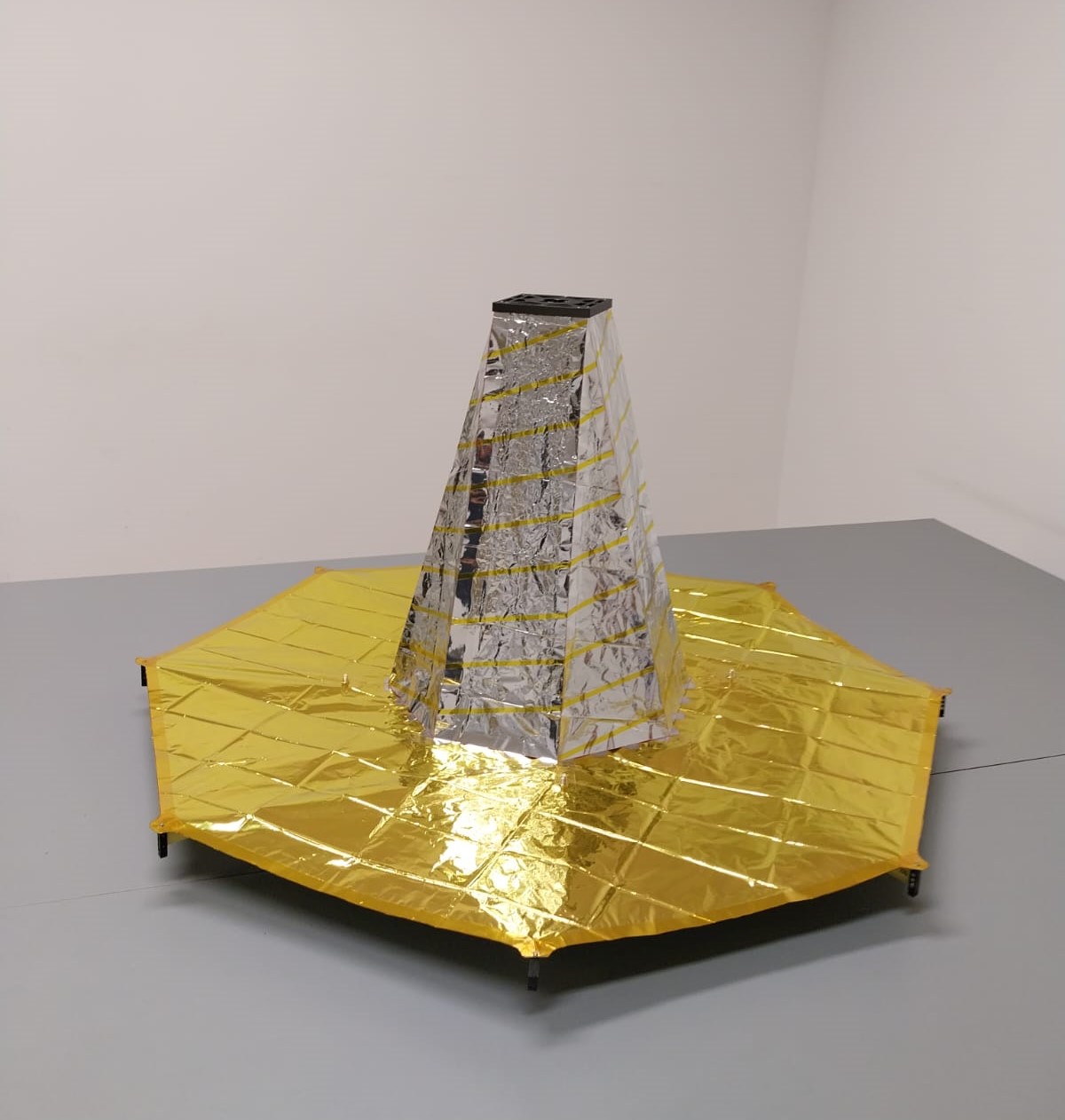

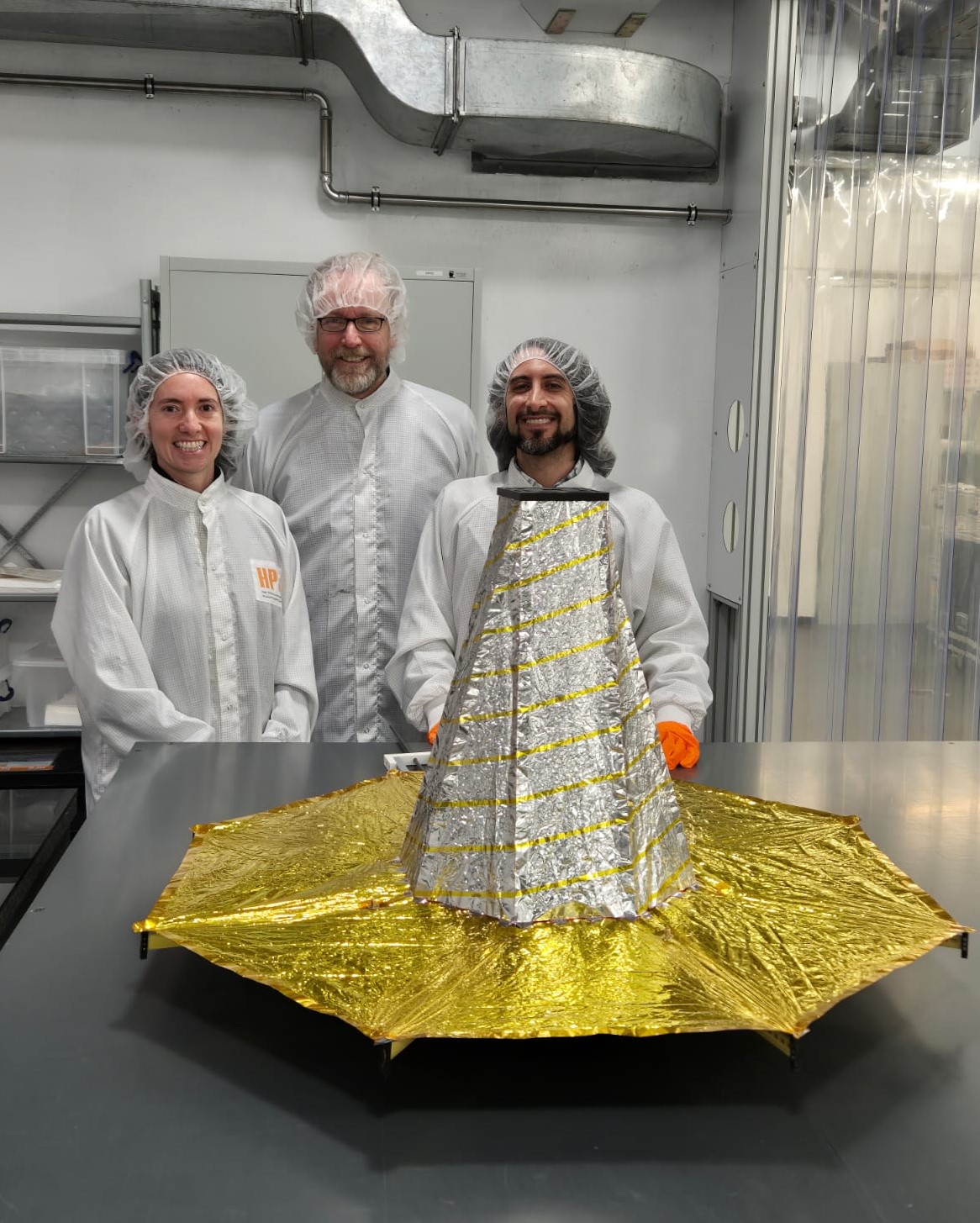

NewSpace relies primarily on small satellites. However, their efficiency is primarily based on antenna performance: the smaller the satellite, the lower the antenna performance and the more expensive it is to technically compensate for this on the ground. The solution from HPS Munich and its Romanian subsidiary in Bucharest: an antenna that can be deployed outside the satellite in the form of a 50 cm high conical quadruple helix and 90 cm diameter ground plane with the additional advantage that it can be scaled to even lower or higher frequencies than the planned bandwidth of between 410 and 460 Mhz but always keeping a gain above 10 dBi. Stowed together for the launch phase, the antenna package is only 10x10x15 cm in size.

ESA was convinced and awarded the development contract in 2018 within its ARTES program to the German specialist for deployable antennas, HPS GmbH in Munich and its Romanian subsidiary HPS S.R.L., Bucharest. In the meantime, the German Space Agency at DLR has provided further ARTES funding to maximize efficient development.

We are delighted that the next major milestone has also been passed with flying colors: the punctual completion of the CDR phase in March 2025. This will now be followed by the production of the engineering model in the second and third quarters and then the test campaign; the contract ends in the fourth quarter of 2025. HPS CEO Ernst K. Pfeiffer comments “With this project completion, HPS will raise UDAN’s maturity level to TRL 6 and then finally to TRL 9 with a planned in-orbit demonstration (IOD). This means nothing less than clear the way for the latest generation of antenna technology on the commercial NewSpace market!”

HPS with ADEO product family: top position in NASA’s technology report extended

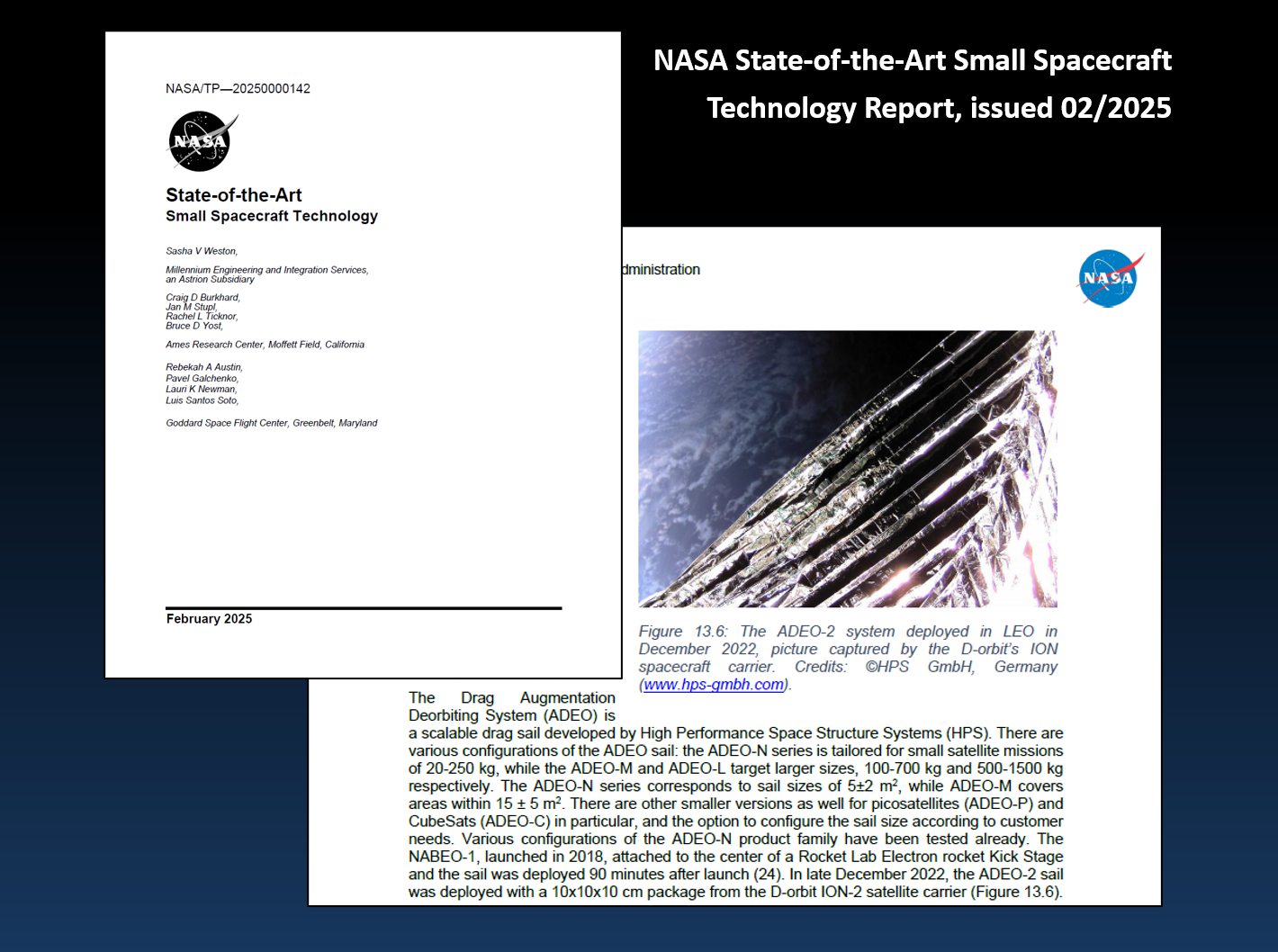

A year ago, the deorbit module from HPS took its place at the top of the podium of the most important technology achievements according to NASA. This was because ADEO already had everything that the American space agency considered crucial for success at the time: top values up to TRL9, scalability and proven flight heritage. Exactly one year later: ADEO, now supplemented in the technology report by the presentation of the bestsellers ADEO-Cube and ADEO-Pico, maintains its position both against numerous Dragsail competitors and against other passive deorbit technologies.

HPS CEO Ernst K. Pfeiffer comments: “With ADEO, we are surfing at the top of the wave worldwide that we have created ourselves with this technology over many years of R&D – often with significant co-financing by ESA and DLR plus considerable company resources. And we are actually delighted with every attempt by other companies to establish deorbit sails on the market: The bigger they make the wave, the higher our product family sails on its crest.”

January 2025

ADEO – Space Heritage

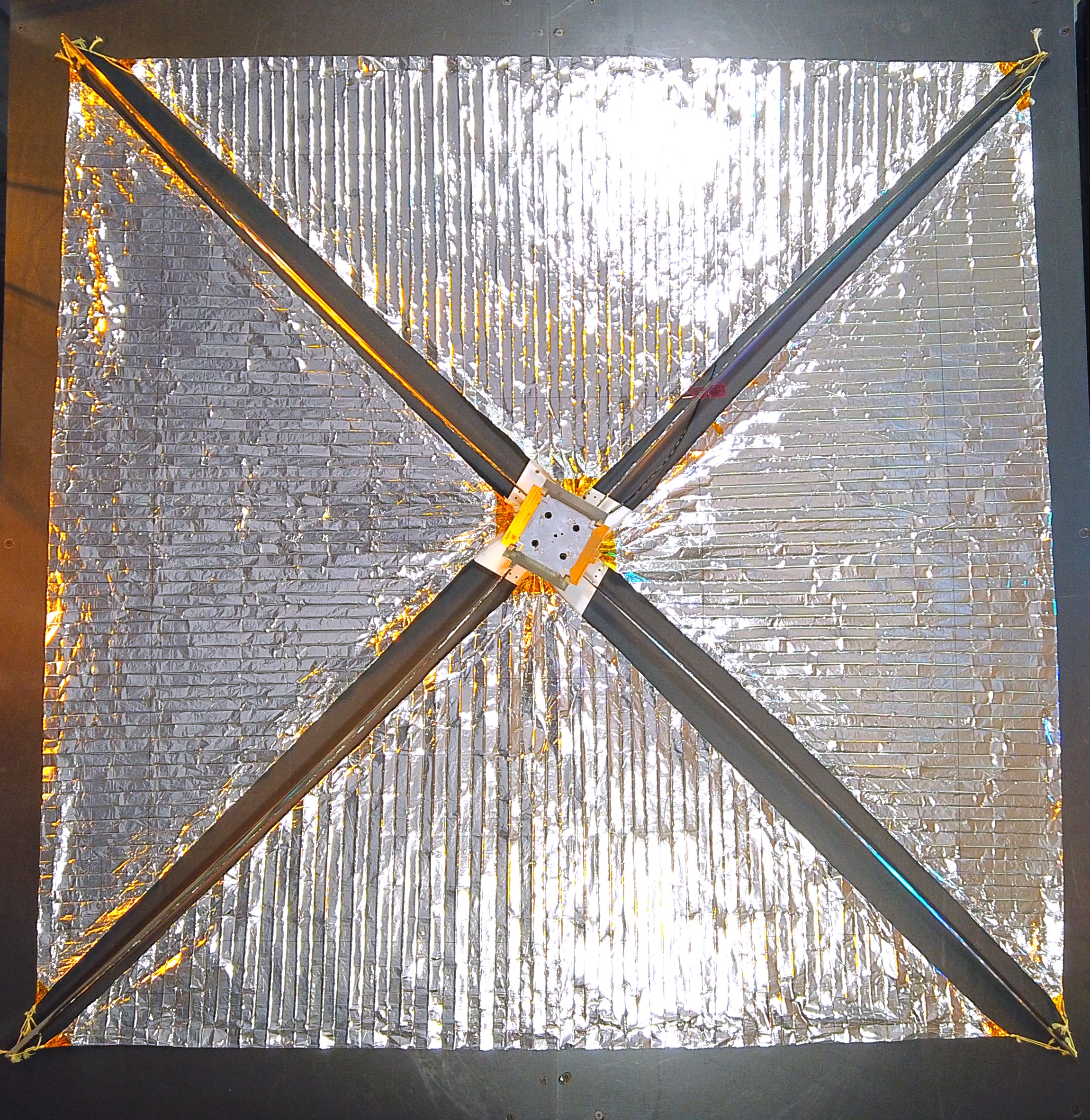

ADEO (Atmospheric Deorbit Sail Module) is the name for an entire product family of drag sails for satellites from the German space company HPS, Munich. They accelerate the disposal of satellites from space to a period of less than five years and thus fulfill the prerequisite for the satellite to receive approval for launch into space in the first place.

The sail is scalable and available in many variants from series production. ADEO-N is tailored to small satellite missions of 20-250 kg, while the ADEO-M and ADEO-L series are designed for larger missions of 100-700 kg and 500-1500 kg respectively. The ADEO-N series corresponds to a sail size of 5±2 m2, while ADEO-M covers areas of 15 ± 5 m2 and ADEO-L 25 m2 and more. However, smaller versions have also been available for a year, especially for cubesats, e.g. an ADEO-P for 1U-6U satellites (1-20 kg) and an ADEO-C for larger cubesats (5-50 kg). A total of five versions are currently available to order, all of which reliably dispose of satellites from LEO – including those from higher MEO orbits when combined with satellite’s onboard propulsion – within the required time frame. A corresponding configurator for selecting the perfectly suitable ADEO module is available for individual mission calculation (ADEO Online Configurator).

Now there is a short film about the production and testing of the product family, as well as ADEO’s heritage story:

Based on over ten years of development, HPS has successfully completed a series of missions up to “full burn” and has thus firmly established itself at the top of deorbit technologies at qualification level TRL 9.

2018: ADEO-N1 (“NABEO”) was launched on a Rocket Lab Electron rocket kick stage back in 2018, with Peter Beck himself (CEO RocketLab) even personally handling the sail. On this flight, the sail was unfurled just 90 minutes after the launch. Visual ground observations confirmed the successfully deployed sail and its performance.

2021: In June 2021, ADEO-N2 (“Show me your Wings”) was launched into space by the spacecraft carrier ION-003 of the Italian launch service provider D-Orbit, as part of SpaceX’s Transporter-2 mission. The successful deployment of the sail in December 2022 was recorded by the ION carrier’s on-board camera. The integrity of the sail after one year in orbit was confirmed, again by means of the onboard camera. On December 8, 2024, HPS received confirmation that ADEO-N2 had completed its mission with deployment of the dragsail at 506 km orbit altitude in a record time of just two years after the 210 kg satellite’s “end-of-business” with fireworks of success at 120 km orbit altitude, beating international rules and regulations by three full years.

Even NASA ranks the ADEO module from HPS as the number one automatic passive deorbit technology in view of the qualification and Flight Heritage.

ADEO is now a bestseller not only with European institutions and companies, but also in the fully commercial markets of the USA and Canada.

Highest qualification levels, proven reliability and flight heritage combined with scalability, availability and attractive pricing make the ADEO product family a highly visible beacon in the global field of deorbit systems for all satellites that must comply with the new 5-year deorbit requirement to obtain launch authorization.

Click here for the latest clip about ADEO

————————-

Video: © HPS GmbH, Munich, Germany, www.hps-gmbh.com

Production: Daniela Creutz, www.bluecirceproductions.com

————————-

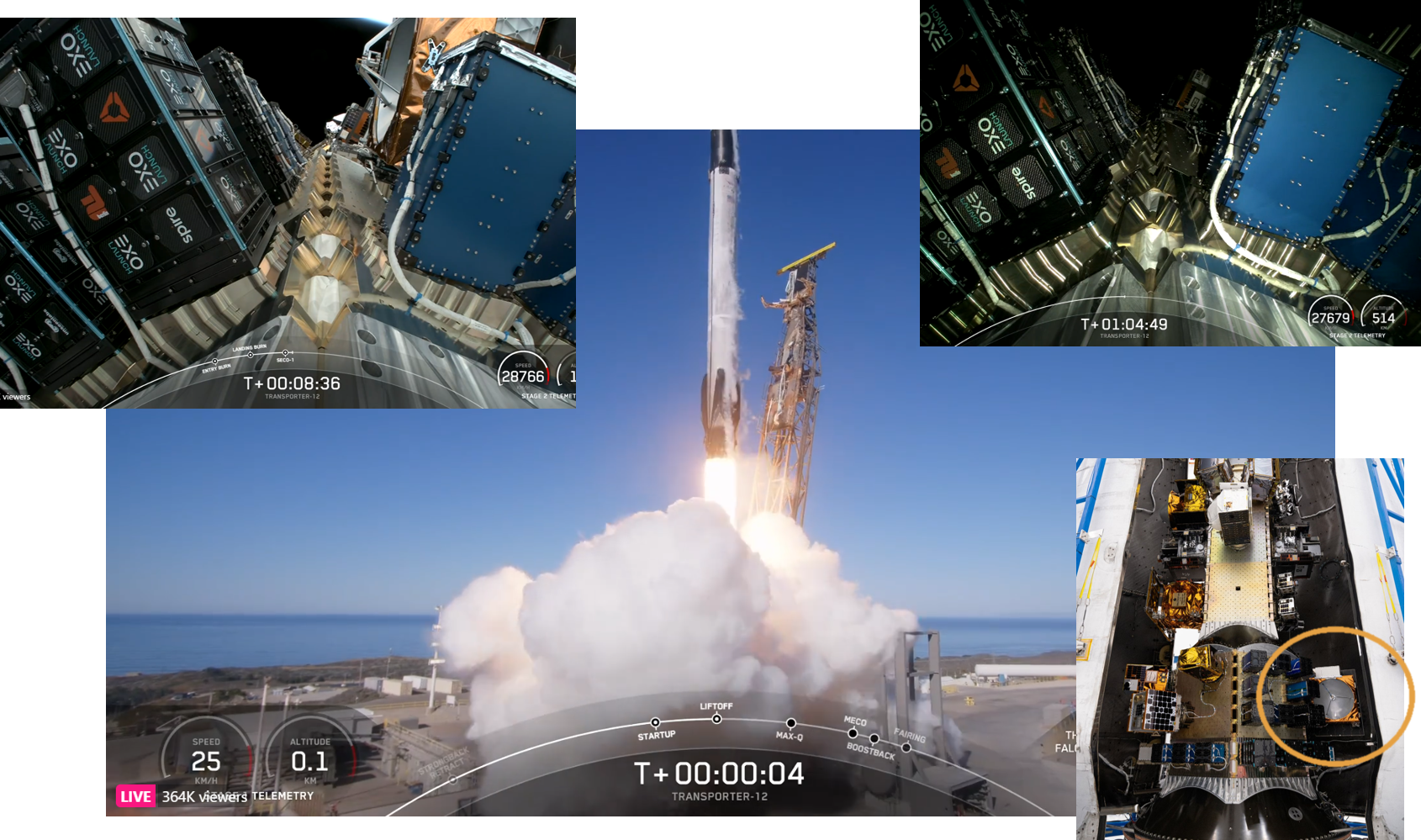

Two HPS contributions on board the Transporter 12 mission on January 14, 2025

Even HPS has never done this before: two of the company’s products are on their way to a sun-synchronous orbit on a Falcon 9 mission. This has been made possible by the rideshare- version of the SpaceX rocket named “Transporter 12”.

On the one hand, the contributions from HPS relate to the highly innovative BANT-1 reflector antenna for Reflex Aerospace’s premiere satellite – see also the HPS news item “HPS congratulates Reflex Aerospace” from today, January 14.

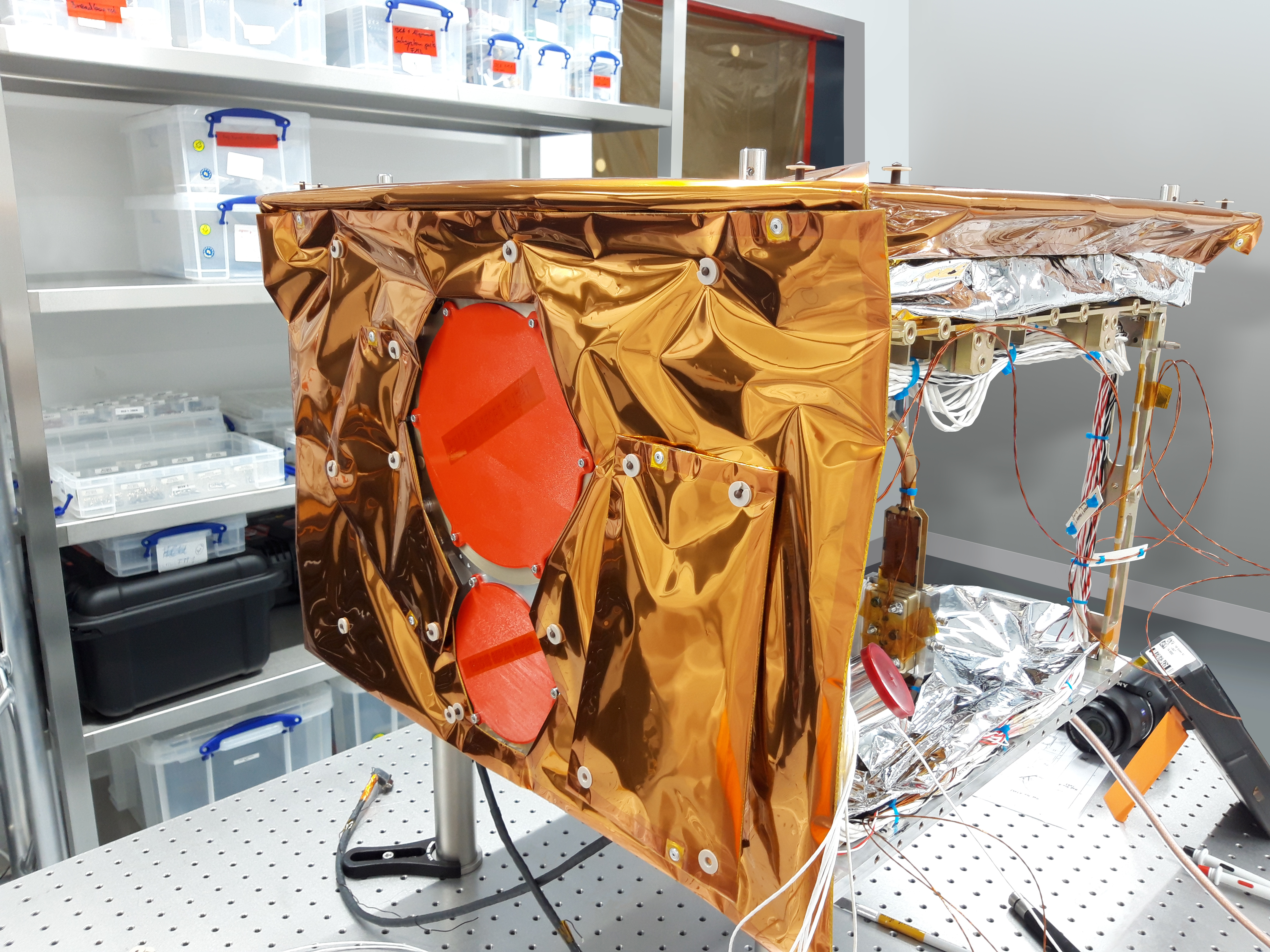

On the other hand, a contribution from HPS itself is the premiere. For the first time, HPS Germany and HPS Romania have jointly prepared a flight hardware with the MLI insulation of the central radiator in such a way that the thermo-optical properties of the satellite are maintained even under the most adverse conditions in space.

The satellite is Sky Bee-1 and part of a thermal infrared constellation HiVE that provides highly accurate yet cost-effective daily temperature data of the world’s land surfaces with a resolution of 30 meters for the benefit of agriculture, urban and industrial environments. The HPS teams of both European countries warmly congratulate their client OHB on the launch success. The first flight model SkyBee-1 is being developed under the InCubed Programme, co-funded by the European Space Agency.

Space premiere also for the innovative BANT-1 reflector antenna from HPS

On January 14, 2025, “SIGI”, the first satellite from the NextSpace company Reflex Aerospace, Berlin/Munich, was launched on board a Falcon 9 – Rideshare Mission Transporter-12. “NextSpace” is the term legally reserved for exclusive use by Reflex to describe the new speed in the development, production and provision of space technology, coupled with innovative versatility as a leitmotif for the performance of the product.

To a large extent, this also applied to an essential element of the satellite not manufactured by Reflex: the core broadband reflector antenna developed by HPS from the medium-sized space technology company HPS GmbH (Munich, Germany) with a cavity-backed spiral antenna as an axial feed for a wide bandwidth and considerable gain – and all that from order to delivery in just 12 months.

HPS congratulates Reflex Aerospace on the first launch of one of its products and looks forward to working with them on further NextSpace challenges in space.

Pictures by SpaceX

Dezember 2024

UDAN – The new generation of communication antennas for small satellites

Disruptive development by HPS for the new space sector

HPS, the Munich-based specialist for innovative antenna technology, has entered the realization phase of a fully functional engineering model (EM) with its in-house development “UDAN”. With the HPS design of a deployable conical quadruple helix, UDAN meets the requirements for the smallest possible space requirement during satellite launch as well as an antenna performance that was previously not possible on small satellites.

See deployment video from UDAN breadboard.

The pack size is only 10x10x15 cm (1.5 U), yet UDAN achieves 10 dBi minimum on usable bandwidth between 400 Mhz and 460 Mhz. When deployed, UDAN measures 50 centimeters in height with a diameter of 90 centimeters. Further scaling across the frequency ranges from 100 to 1000 Mhz is planned in order to diversify the service requirements of the communication satellites.

The development is being funded by ESA as part of the ARTES programme, while the German Space Agency at DLR is providing additional funds to maximize development efficiency.

This brings the completion of the CDR phase for February 2025, the production of the engineering model in Q2-3, followed by the test campaign and the closure of contract by Q4 in 2025. With the final completion of the project, UDAN will reach maturity level TRL 6, the in-orbit demonstration (IOD) which is planned to follow in Q2 2026 will then finally raise the HPS innovation to TRL 9 and thus reach out for the commercial market.

November 2024

HPS and EXOLAUNCH: Making Space Clean Again

HPS is happy to join forces with the Germany-based Exolaunch and is fully engaged to support customers of Exolaunch by enabling this very special and successful NewSpace-launch service provider to grant priority access to the delivery schedule of flight-proven ADEO* deorbit sails which are currently in high demand.

EXOLAUNCH’s COO Jeanne Allarie and HPS’s CEO Ernst Pfeiffer signed an Agreement on Space Tech Expo 2024 in Bremen in a great joint spirit (see pictures) the ambitious endeavour of

- being a role model for a sustainable use of space and

- of raising awareness with all potential customers on an existing solution for deorbiting: ADEO-modules are easy, affordable and reliable to contributing significantly to Making Space Clean Again.

See for the respective EXOLAUNCH announcement

(* ADEO-modules are needed to allow a satellite deorbit after its “End-of-Business” within five years; satellites without this or any kind of deorbit accelerator do not get clearance for launch anymore.)

November 2024

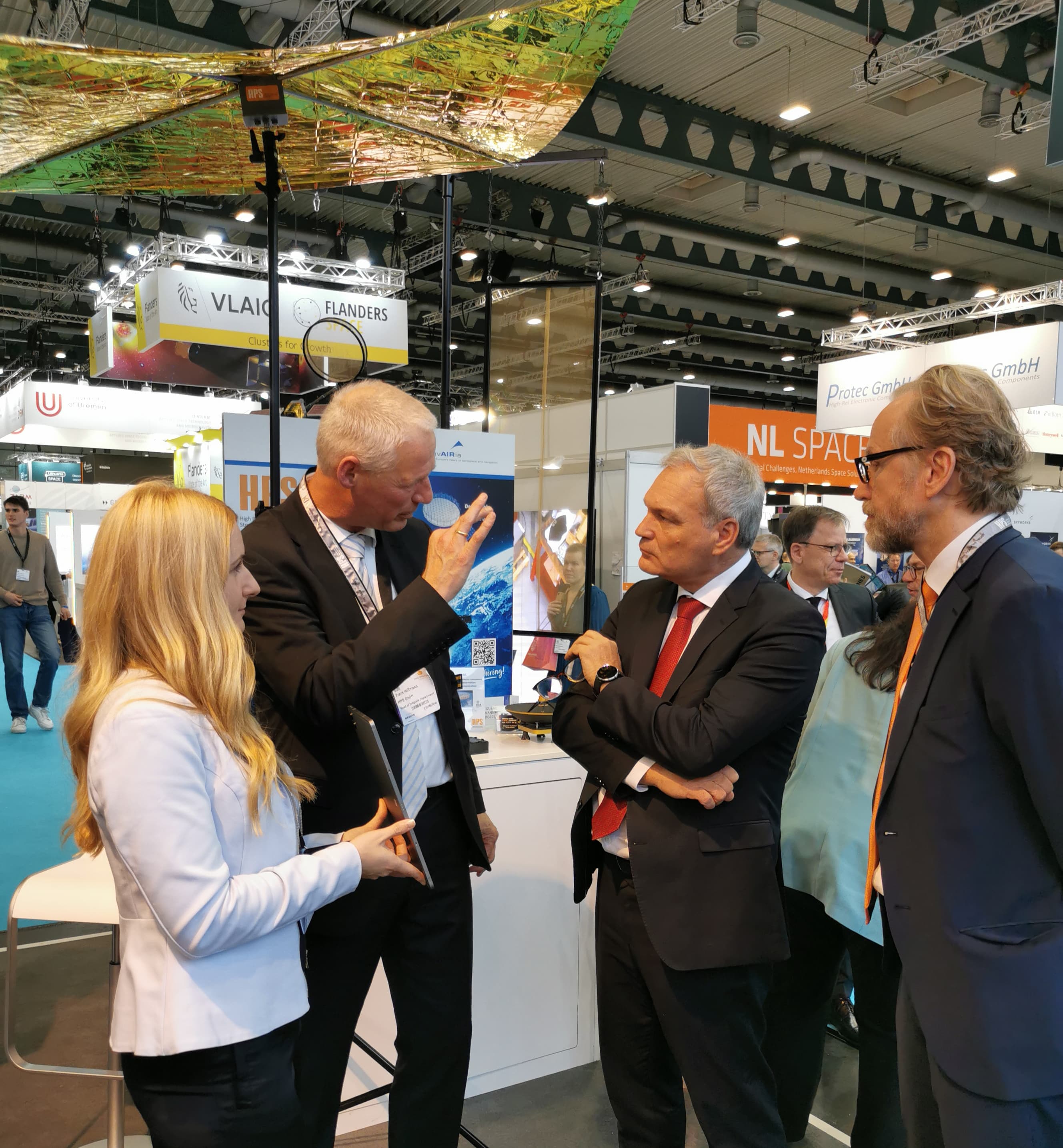

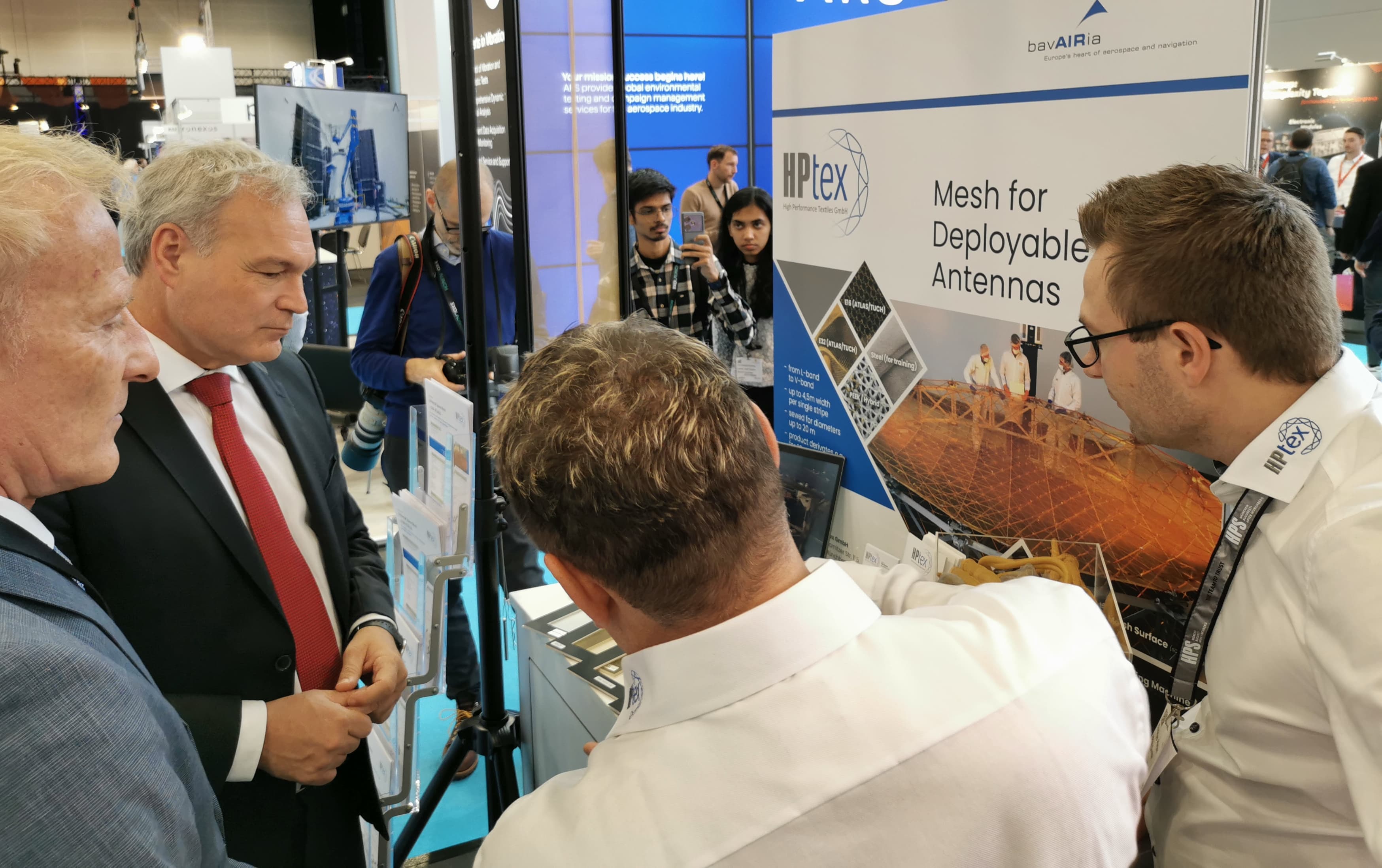

German space agency chief Dr. Walther Pelzer and DLR delegation focus on visit to HPS Group

During the traditional DLR delegation round on the opening day of the Space Tech Expo in Bremen, the head of the German Space Agency at DLR, Dr. Walther Pelzer, focused his attention on SMEs in the German space industry. Special attention was paid to the innovation forge HPS. And it was represented in groups: with HPS Germany (Munich), HPS Romania (Bucharest) and the joint venture company HPtex (Münchberg, Germany).

With reference to pioneering antenna projects such as HERA and EUCLID, company boss Ernst K. Pfeiffer emphasized the leading position Germany has gained in special antennas for space missions. HPS is also positioning itself as a leader in the commercial sector with the successful ADEO braking sail project, which ensures compliance with the new 5-year rule for satellite deorbiting and thus keeps the satellites ready for launch.

In his role as spokesman for German space SMEs, Ernst Pfeiffer also took this opportunity to emphasize the enormous importance of the DLR and ESA’s capability-enhancing technology programmes for SMEs as the innovation backbone of the industry. According to Pfeiffer, the precise promotion of the technological capabilities of SMEs via dedicated competition areas reserved for SMEs is irreplaceable.

Live demonstrations, e.g. of a functional model of the ADEO brake sail or a scaled model of a deployable large antenna reflector, supplemented by product demonstrations from HPS-Romania (e.g. radiator) and from HPtex’s MESH production (e.g. Ka-band mesh sample for use in the Copernicus mission CIMR) rounded off the visit program.

November 2024

New laboratory for mesh research at HPS

The Munich-based space technology company HPS is a joint venture partner of Iprotex-GmbH; both are equally involved in the joint company HPTEX in Münchberg near Bayreuth. This is where the flexible reflector material “MESH” is tailor-made and of the highest consistent quality for applications such as small and large deployable space antennas.

The market for mesh is divided among a small number of players worldwide. To survive here, continuous development is an essential prerequisite. HPS has therefore recently set up its own mesh research laboratory at its Munich headquarters on Hofmannstrasse. The initial team of two specialists is currently being expanded to include a further engineering position. The initial equipment of the laboratory for the further development and optimization of HPTEX mesh has already cost HPS 50,000 euros; among other things, investments were made in a mesh tension jig (stretch test rig) including an HD camera system. In addition, for yet another 50k euros the whole basement-area of the HPS building has been improved to host capacities for assembly work on ADEO brakesails in serial production.

Customized service is a top priority at HPS, so the new laboratory also carries out contract research, e.g. in a project called VMESH, in which a mesh for the very high frequencies in the V-band is being developed. The laboratory’s ability to carry out multiple iterated processes to measure the stretchability of antenna meshes is also unique on the market.

In addition, HPS is Europe’s only supplier of large deployable antenna subsystems with its own mesh production. The company’s flagship project is the ESA Copernicus Mission CIMR. HPTEX also serves customers from all over the world, including Europe, the USA, the United Arab Emirates, South Korea, Singapore and Taiwan, with the support of the new laboratory at HPS. The mesh is manufactured at HPTEX itself.

Oktober 2024

HPS Prominently Present at the IAC in Milano

Participating in the International Astronautical Congress, IAC, has developed into a good tradition at HPS over many years. This year, the company will be represented by Ernst K. Pfeiffer, CEO, together with ADEO project manager Mrs. Dorittya Milankowitch from HPS Munich and Horatiu Gheorghe as IAC-contact point for HPS Bucharest with products like secondary structures, thermal hardware and purging equipment. The HPS-team will keep up full presence during all five days of this international event.

Special highlights will be the company presentations; they are going to take place on Friday, 18th, from 10.15 to 10.45 a.m., and also as part of the Company Slam at the booth of the German association BDLI on Tuesday from 13.15 to 13.45 p.m..

Focus of both presentations will be on the product family of the ADEO deorbit sailsystem for automatic disposal of satellites after their end of mission, serving the idea of clean space, sustainability and debris avoidance even from the beginning of the satellite´s journey.

Main products besides ADEO to be asked at our booth: reflector antennas, deployable antennas, large deployable reflector subsystems, mesh, thermal hardware, purging equipment. HPS will warmly welcome there all its customers from both worlds: classic and NewSpace. For a dedicated prearranged business meeting please send a message to Contact@hps-gmbh.com.