May 2021

D-Orbit (Italy) and HPS (Germany, Romania) agree on flight for

ADEO on ION Satellite Carrier in June 2021

After 6 years of development, including a zero-G parabolic campaign and a first test flight end 2018 with Rocket Lab’s ELECTRON, HPS signed on 30.04.2021 the contract with D-Orbit for the flight of the ADEO-N, named „Show me your Wings“, on the space logistics company’s orbital tranportation vehicle ION Satellite Carrier. The launch of the „Wild Ride“ Mission will take place already summer this year from a launch site in USA.

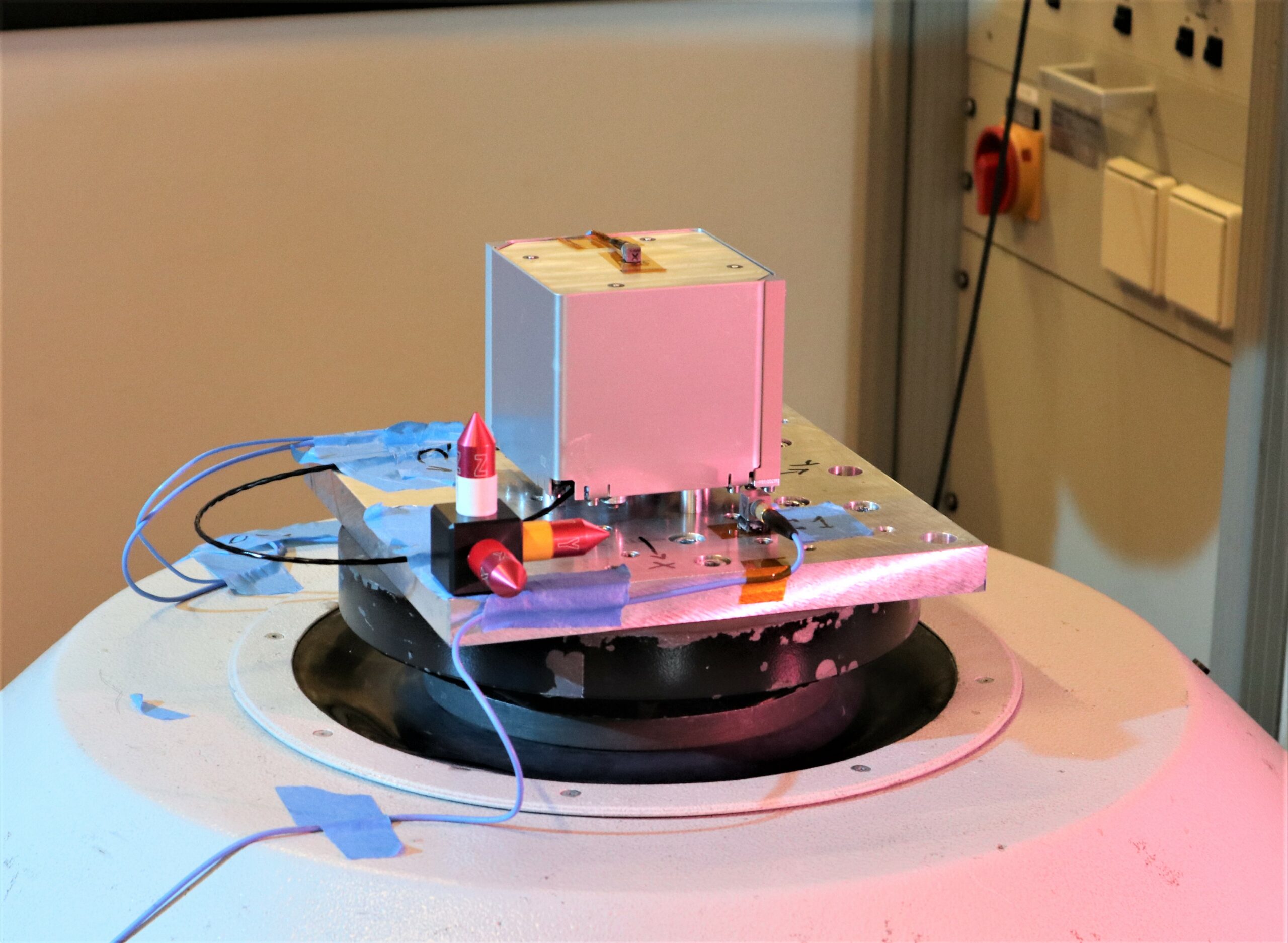

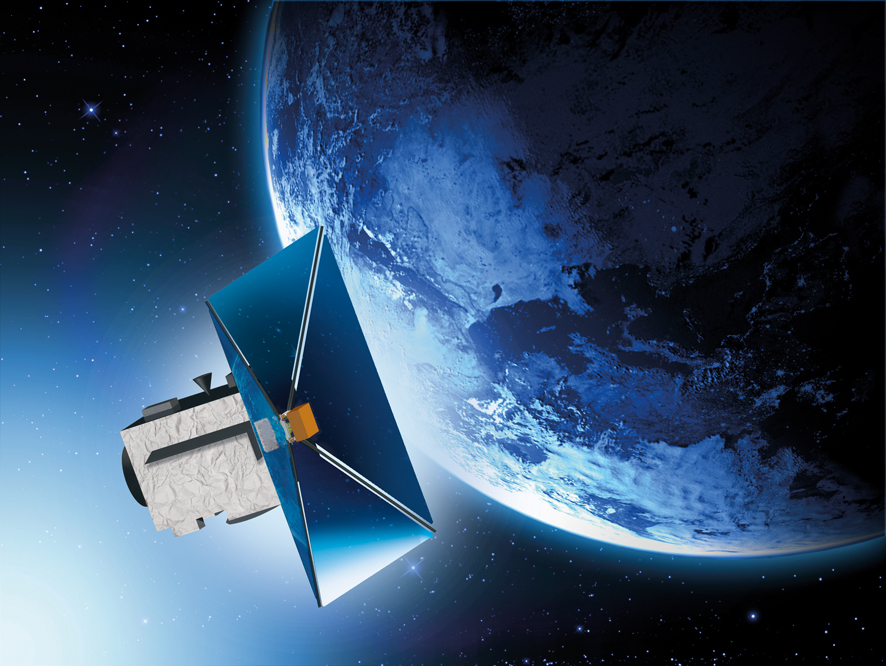

ADEO, the world’s only industrial NewSpace drag sail of its kind for the multiple accelerated return of retired satellites, is available from HPS in different versions tailored to the size and weight of the spacecraft in question. In this case, it is one of the smallest versions, weighing less than one kilogram, with dimensions of only 10x10x10 centimeters and a sail area of 3.6 square meters. It has been integrated directly into the ION platform at D-Obit now, mid May. ION is a space vehicle that can transport satellites in orbit and release them individually into distinct orbital slots. At the end of the nominal ION-mission, in front of its “eyes” of the integrated cameras, the ADEO braking sail module unfolds, shows its „wings“ and leads ION to residue-free disposal by incineration in the atmosphere much quicker than without the sail. The first 100 km of descent will be monitored intensively.

HPS CEO Ernst K. Pfeiffer is convinced that ADEO came at exactly the right time to promote sustainable NewSpace development by avoiding the threat of apocalyptic space debris scenarios, despite rapidly growing constellations. In this context, Pfeiffer emphasizes the excellent R&D support provided by engineers and test facilities of the DLR Institute of Space Systems in Bremen, as well as the various economic development support contracts and grants provided by ESA, DLR and the Free State of Bavaria.

The implementation of the technology developed by HPS’s NewSpace Team at Munich headquarters was largely supported by the hands of engineers and technicians of the Romanian subsidiary and Romanian workshops. This is now, according to Pfeiffer, our clear advantage having all in one company: heritage from institutional space, a tailored „internal start-up department“, a steadily growing house in Bucharest and several trustful development and production partners. New and expanded challenges to innovation and manufacturing are already waiting.

According to Renato Panesi, co-founder and CCO of D-Orbit: „We are very happy to have a chance to work with HPS on this project: sustainability in general has always been a relevant aspect of our identity, and with HPS we share a common vision aiming to a sustainable access to space. Being able to help HPS to test a new and innovative technology like ADEO to help control the increment of space debris is a point of pride for us. To HPS is reserved the grand finale of the mission and, while we are going to „enjoy the ride“, we are really looking forward to it“.

March 2016

ESA-Prime HPS with SME-Consortium Ready to Build New Generation De-Orbiting Subsystem

Hardly any messages have dominated the space community´s discussions in the past two years as perseverently as these two:

- the debris from past satellite missions forms a growing threat to future endeavors in space

- the number of satellites expected to form future constellations especially on LEO is exploding since new players are discovering space as their domain

- which again multiplies the problem of future debris.

So, on the one hand enormous growth of the satellite business is to be foreseen, on the other hand this business needs better rules in order to be sustainable. „Clean Space“ is ESA´s answer in general and the quest for a new, fully ecological de-orbiting sailsystem in particular.

While currently satellite manufacturers are already facing problems to comply with the 25-years-deorbiting „guideline“ without minimising the effectiveness and increasing the cost of their missions, ESA now aims to make this period as a strict requirement leaving neither ecological nor economical footprints.

Capitalizing on previous research and development in this area like the precursor project ADEO, led by the subsystem prime HPS with its consortium of DLR-institutes in Bremen and Braunschweig and the SMEs Etamax and HTS, ESA now announced its expectations for a full fledged demonstrator ready to fly by 2018 with a deorbiting time of lower than 5 years. The new project will be ignited this year and ESA´s subsystem prime HPS is expected to take this next step towards the final breakthrough in deorbiting technology, too, because:

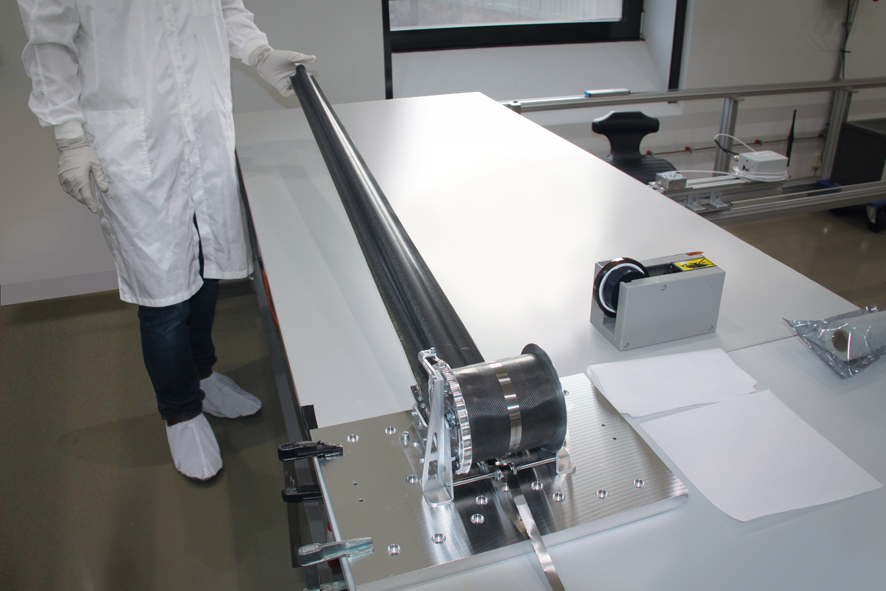

- the current HPS precursor project ADEO, featuring a 5m x 5m deployable boom and sail subsystem weighing just 20kg, has been successfully tested on breadboard level in February 2016 and will reach design maturity for an Engineering Model manufacturing and assembly through a CDR in these days in March.

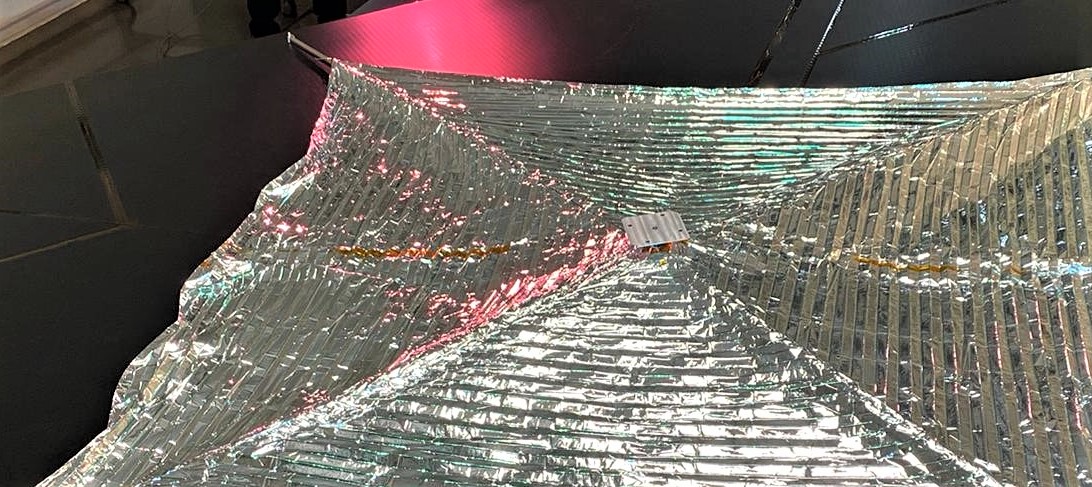

- ADEO will then already fulfill the requirements of providing sail and boom materials able to withstand the very severe Atomic Oxygen (AtOx) and Ultra Violet (UV) environment, offering scalability down to 100-kilo-satellites down from the current reference case of spacecrafts at 1-1.5 tons of weight, and of providing reliable deployment technology tested under ambient conditions and in a vaccum chamber in mid 2016.

HPS as ESA subsystem prime is aiming at the follow-on project also with its proven partners.

In parallel and as leading specialist on deployable structures and antennas, HPS Germany acts as prime contractor for Large Deployable Antennas (LDA) in cooperation with the German SME LSS, while the HPS subsidiary in Portugal is working on a deployable highprecision mast system (10-20m) for instruments weighing 100-250 kg on science missions.

June 2018

Just a few weeks before the launch of „Pride of Bavaria“, the space test mission of the nano-version of the space sail system ADEO for fast deorbit of decommissioned satellites, Bavarian minister of economy Franz-Josef Pschierer paid a personal visit to HPS, the Munich based driver of spacetech innovations. Founder and CEO of HPS, Dr. Ernst K. Pfeiffer, explained the ADEO-system designed to avoid space debris – a unique development which has been funded by Bavaria – and also introduced other important product lines to the minister: reflectors for antennas serving earth observation and telecommunications projects in space, which today are the European benchmark in high frequency data transmission, thermal and radiation protection systems, large deployable antennas, and a high-precision mesh-net for the reflection of antenna signals – developed by HPS and produced in Hof, center of the Bavarian industrial „textil triangle“. (Links to tv-coverage/interviews: https://www.sat1.de/regional/bayern/videos/die-sendung-vom-25-05-2018-ganze-folge)

On Saturday, May 26th, the HPS-crew took the ADEO flight model plus a spare to the launch site in New Zealand. ADEO will be launched end of June aboard an American ELECTRON rocket of RocketLab (lLinks: http://spacenews.com/rocket-lab-reschedules-next-electron-launch/; https://www.rocketlabusa.com/)

September 2018

3 million more for next-stage development of deorbit device ADEO

With the support of the German Space Agency delegation HPS has been awarded a 3-million Euro GSTP-contract with ESA for development and manufacturing of a large passive dragsail version of ADEO with presumably about 25 squaremeters in size. The goal of the activity is the delivery of a flight ready protoflight model prepared for an in orbit demonstration mission as early as 2020. Final design and size – on the basis of a market analysis currently undertaken– will be frozen in December 2018.

Like projects on system level, for example, ARIANE, GALILEO and COPERNICUS, ADEO on the subsystem level is classified as one of Europe´s „lighthouse projects“ in space, since

- a solution for fast deorbit of satellites especially from the very crowded LEO orbits at 300-750 km perigee is the absolute prerequisite for sending future single satellites and even whole constellations of short-lived satellites into space in the first place

- ADEO by HPS is Europe´s top chance to gain and keep the globally lead position on the emerging world market with a critical technology ensuring the continent´s independence in space.

- ADEO will in the end address the market commercially and consequently create new jobs as well as contribute to yet another increase of the return-on-investment ratio of public funding in space.

While a 2.5 squaremeter ADEO-N test version is waiting in New Zealand to go on its „Pride of Bavaria“-mission on top of the Electron rocket (#ItsBusinessTime of Rocket Lab USA), this second development – ADEO-L – represents an upscaled version of just 10 Kilo mass and 25 squaremeters enabling passive de-orbiting without the need of any extra propulsion. Due to its virtually unlimited variability and scalability ADEO can be applied to return dead satellites of any size and mass. For example, the current version supported by ESA (and DLR) will reduce the time for disposal of a 500 kg satellite at 650 km altitude from 460 years down to just 11 years, while the small version currently mounted on top of Electron could drag for example a 10 Kilo cube satellite (6U = 30cm x 20cm x 10cm) down from a 500km orbit in 77 days instead of 26 years.

The large version is planned be applied as a protoflight model to a 200-1000kg satellite with an In-Orbit Demonstration as early as 2020. The In-Orbit Demonstration planning phase has already started and HPS is looking among other things for satellite providers that would take the PFM onboard their missions free of charge.

The ADEO subsystem is designed, assembled and tested by HPS as prime contractor of ESA and supported by eight subcontractors, 5 of them being SMEs. Main subcontractors are DLR institutes Bremen and Braunschweig and RUAG Space Germany (formerly HTS).

Dragsail technology demonstration mission NABEO-1 (ADEO dragsail family) successfully launched into space on Rocket Lab’s Electron #ItsBusinessTime

November 2018

On the 11th of November at 4:50am Central European Time, the HPS GmbH developed NABEO-1 dragsail technology demonstrator was launched into space onboard the Rocket Lab Electron rocket #ItsBusinessTime. This dragsail is a means to passively remove satellites from highly congested Low Earth Orbit regions after their mission life without the need for the spacecraft to be still alive.

With a dragsail area of 2.5m2 deployed from a cubesat sized box (<1U: 10cm x 10cm x 10cm) the NABEO-1 dragsails fit right into the ADEO-N dragsail class for cube and nanosatellites. Further developments for dragsails for larger missions (ADEO-L for 100-500kg satellites) are currently undertaken at the ESA GSTP/CleanSpace activity ADEO which will lead to a qualified dragsail Protoflight Model in 2020 with a follow up In-Orbit Demonstration Mission right after.

The opportunity to fly the NABEO technology demonstrator on the #ItsBusinessTime mission was offered by Rocket Lab (Huntington Beach, CA, USA / Auckland, New Zealand) and Ecliptic Enterprises Corporation (Pasadena, CA, USA) via Ecliptic’s Hosted Payload Program (HPP), with NABEO-1 serving as a pathfinder for demonstrating the Electron rocket’s hosted payload capabilities. The NABEO-1 subsystem development at HPS GmbH was co-funded by the Bavarian Ministry of Economic Affairs, Energy and Technology. The foundations for the dragsail technology have been laid in 2017 by joint research activities between the DLR Institute for Space Systems (Bremen), Fraunhofer Ernst Mach Institute (Freiburg), and HPS GmbH (Munich).

The #ItsBusinessTime rocket was launched from Rocket Lab’s Launch Complex 1 at the Mahia Peninsula on the North Island of New Zealand. The NABEO-1 subsystem was attached to the kick stage (3rd stage) of the Electron rocket and stays on the kick stage for its deployment which was commanded 2 hours intro the flight. Currently, the team at HPS GmbH is waiting for a confirmation of the dragsail deployment with the help of the Falcon Telescope Network who will also try to investigate the de-orbit behavior of the kick-stage with the attached dragsail via their optical telescopes.