August 2024

HPS Space News

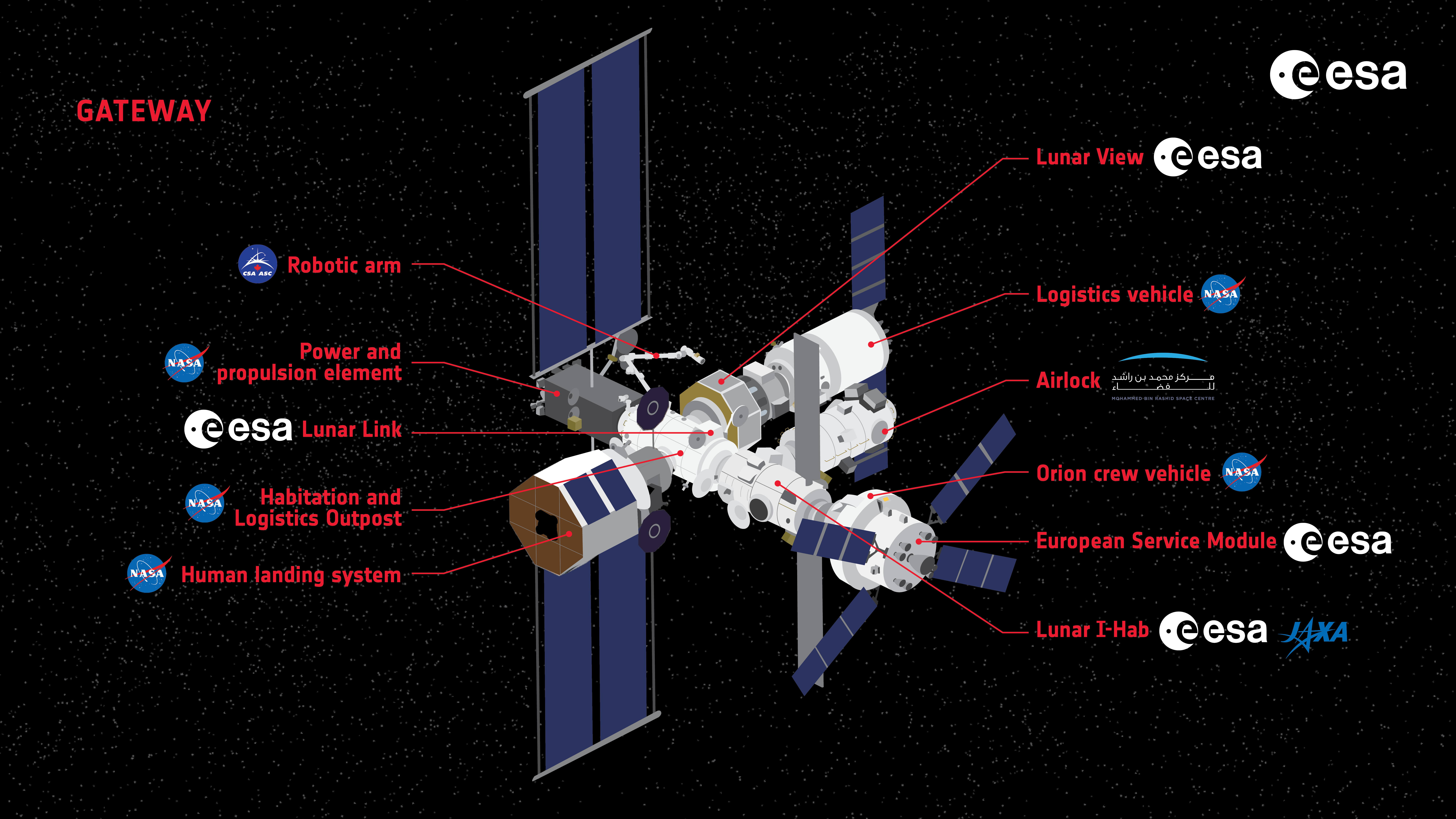

On the way to the moon: HPS secures participation in the humanity project I-Hab with a German SME consortium

It is one of the most ambitious international space programs of our time: Artemis, the return to the moon to stay on this most distant outpost of mankind. At the ESA Ministerial Council Conference 2022, Germany subscribed to the European work package under the name GATEWAY with a contribution of twentyfive million euros and the expectation that SME consortia in particular would be given the opportunity to demonstrate their skills.

The Munich-based space technology company HPS, which had already qualified for the contract to provide the Antenna Reflector Assembly (ARA) as a core element of the ESPRIT LUNAR-LINK, now presented its SME consortium. On August 8, 2024, HPS Germany with its SME consortium of proven cooperation partners signed the multimillion Phase C/D contract with the mission prime TAS-Italy and took on the task of developing and manufacturing the so-called “Internal Secondary Structures”, i.e. lightweight panels, hinges and brackets, following Phase B2, which began in 2021 – in a nutshell: to provide the central elements that hold the interior of the habitable I-Hab together while it orbits the Earth’s satellite as a “bus stop moon” and represents the supply hub for all activities around and on the moon.

With great emphasis and intensive commitment, prime contractor TAS has created in the past weeks the conditions for HPS to be able to schedule the kick-off for all project-consortium under its leadership for August 13, based on the written contract in the middle of the summer; this applies in particular to Astrofeinwerktechnik (Berlin), HPS-Romania (Bucharest), INVENT GmbH, Braunschweig, Space Structures GmbH (Berlin), SpaceTech GmbH (Immenstaad). The security of having the right partner in HPS and its consortium for Europe’s part in this extremely demanding humanity project can also be drawn by the Group Prime from the success of an HPS consortium in other highly complex tasks such as the deployable giant antenna for TAS Rome as part of Copernicus CIMR.

In addition to a series of small and large technology projects, in which the company involves other SMEs whenever possible, HPS has now also assumed the role of central “SME enabler” in the supreme discipline of space technology for astronautical survival infrastructure and supply.

HPS CEO Ernst K. Pfeiffer reacted to this renewed vote of confidence with great enthusiasm: “I can say for HPS and all our subcontractors involved without exaggeration: this is a milestone for German SME-industry in the history of international space travel and for all of us more than just a piece of technology. We are creating something here that will go down in the history books of nations; in addition to all the challenges for the engineer, participation is an honor that we are all determined to earn. In keeping with the image of the Olympic Games having took place: this job is the gold medal with value for eternity. Countless videos and live broadcasts of astronautical activities using our technical facilities over many years will keep the memory of this achievement alive for generations.”

Delivery of the qualification models is scheduled for mid-2025, with the flight-assemblies to be delivered to TAS a year later. The launch is scheduled for 2028. Prior to this, there will be intensive discussions in the autumn on all ongoing processes and the “Delta Work” action area, which have been postponed for the time being in favor of the earliest possible start of the work.

August 2024

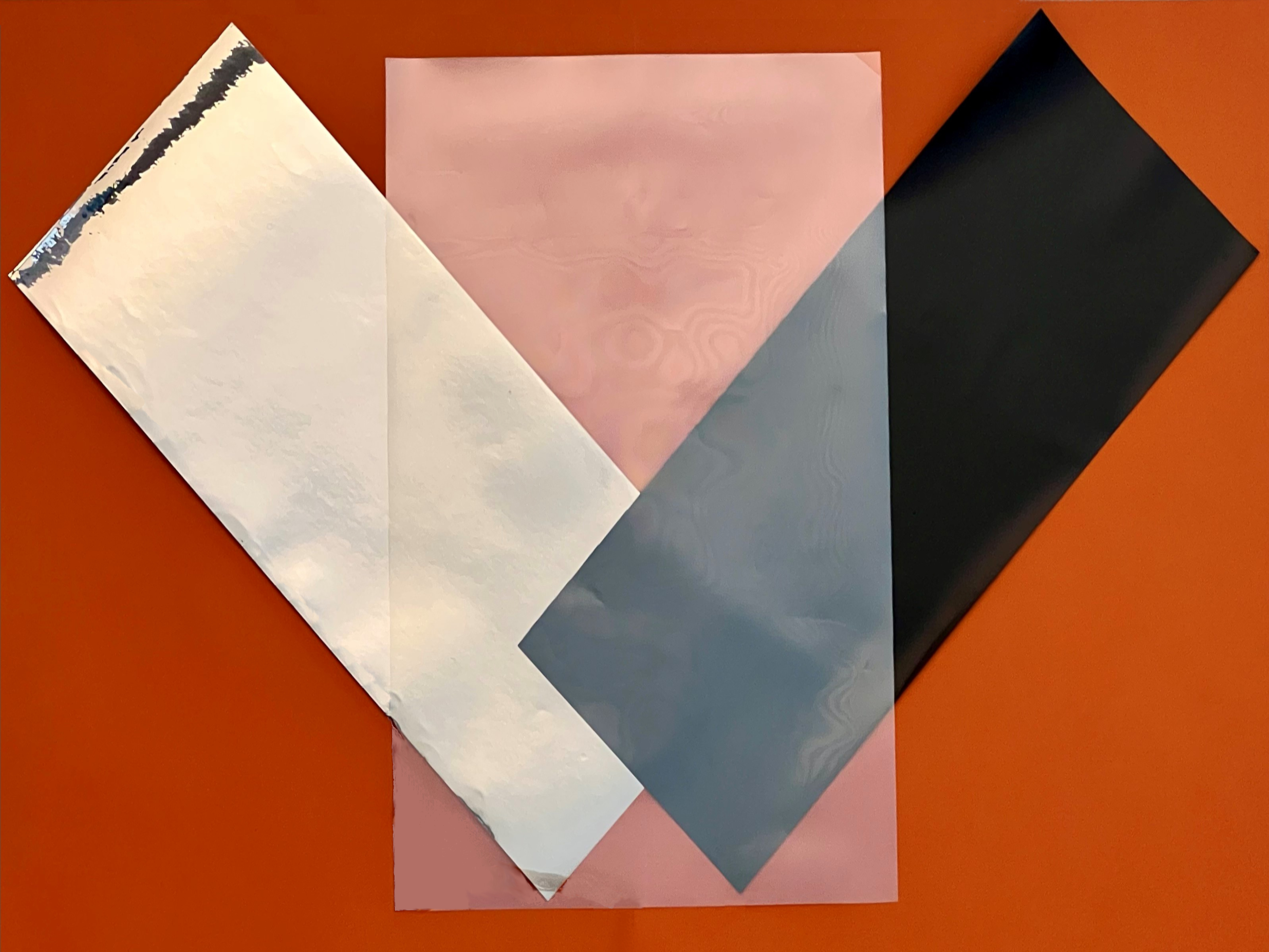

ESA: 1 million for product innovation by HPS, AAC and DLR

ESA’s GSTP program is one of the European Space Agency’s most important instruments for promoting new technologies, particularly those generated by SMEs. The program also enjoys high priority in the overall ESA portfolio at the German space agency; the corresponding financial resources now also enable the launch of a new sub-program called “Product Initiative”. With the signing of the contract on August 7, 2024, ESA and HPS as the main contractor gave the go-ahead for the first technology project in this category.

It took just over six months from the idea to the signing of the contract; the funding amount is one million euros. The Munich-based space technology company HPS and its long-standing partner, Vienna-based Aerospace & Advanced Composites GmbH, are contributing 20 percent of their own funds, while the DLR Institute of Space Systems in Bremen is also on board on the research side. Over the next 24 months, highly innovative films (working name “ProFilm”) will be developed in various thicknesses and surface configurations and for large-area applications, which are characterized by two special features in particular:

- they are resistant to the chemically aggressive residual oxygen molecules (ATOX-resistant) and are therefore perfectly suited for use in particular in the highly frequented low earth orbit LEO area,

- Special derivatives are invisible or non-reflective.

In addition to use as thermal insulation for satellites, this also results in innovative applications as invisible brake sails as a further development of the HPS ADEO product range for deorbiting decommissioned satellites.

In this way, they serve four strategic goals of European space:

- Securing technological independence from other major spacefaring nations that have already made progress in this area

- Support European manufacturers of spacecraft and satellites, for whom maximum physical protection is an element of the competitiveness of their products

- Avoidance of astronomy-hostile light pollution in space through non-reflective surfaces on dragsails and thermal insulation such as MLIs and SLIs. There are also plans to use them for solar panels and radiators.

The ideas go as far as deployable structures that could make entire satellites invisible with ProFilm.

HPS CEO Ernst K. Pfeiffer is enthusiastic about the start of the project: “The innovation processes that have now been initiated will result in highly exciting products – the cooperation with our partners, DLR in the north and AAC GmbH in the south, alone is a guarantee of this. Above all, however, this premiere of ESA’s new GSTP sub-programme shows how quickly and effectively the European space agency can identify, accept and master technical challenges. This is exactly what European space travel needs, and this is exactly what innovation drivers from the ranks of SMEs need in particular.”

July 2024

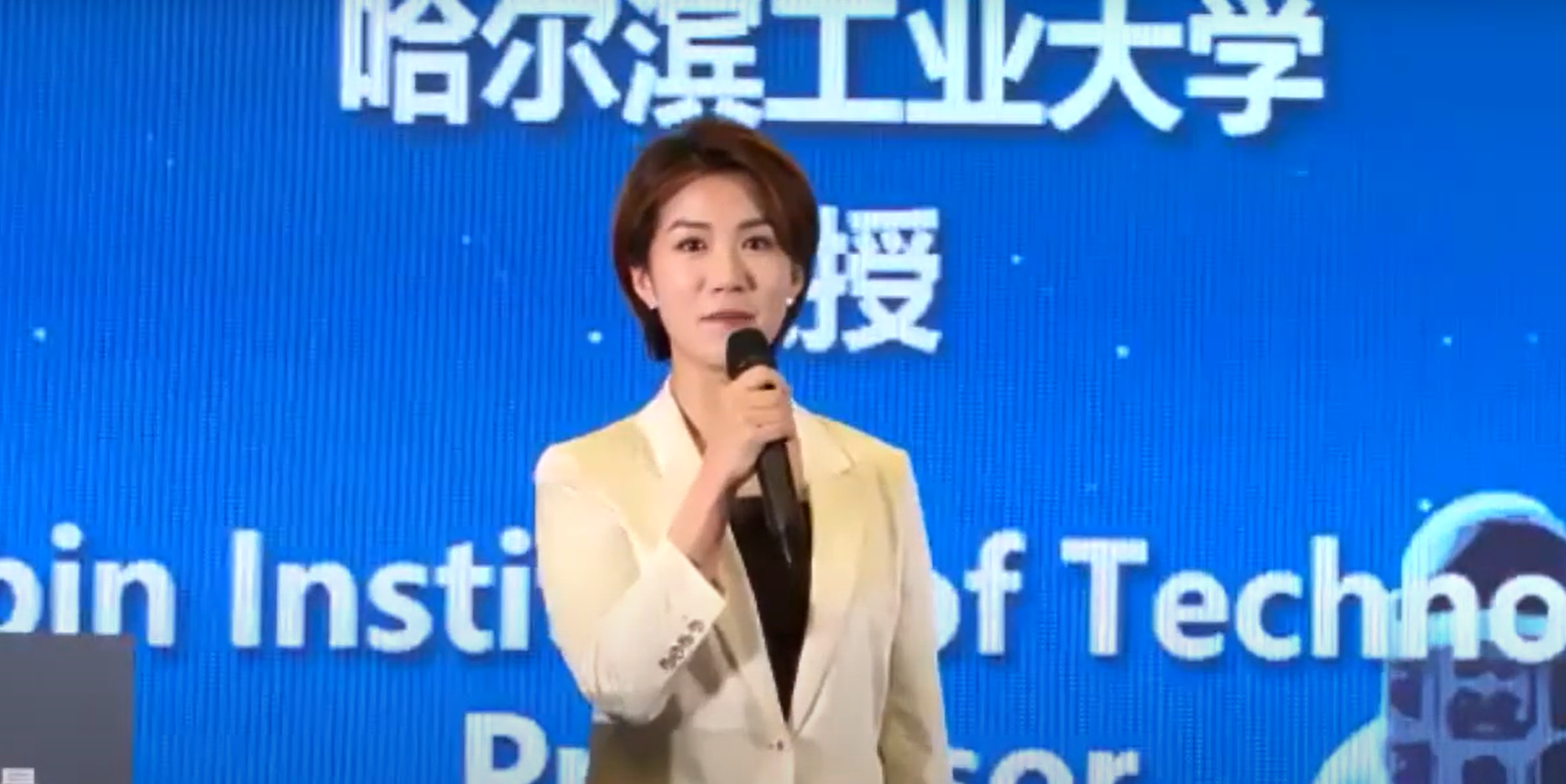

HPS CEO as speaker from Europe at the International Day of the Moon in China

On Saturday, July 20, 2024, the fourth International Moon Day, proclaimed for July 20 of each year by the United Nations General Assembly with Resolution 76/76 on “international cooperation in the peaceful uses of outer space”, took place. The physical venue this time was China. Participants came from the United Nations / UNOOSA, the USA, India, Saudi Arabia, Japan and Europe/Germany, among others. Dr. Ernst K. Pfeiffer, CEO of HPS in Munich, had the honour of flying the flag for the latter at this high-level event, which was connected via video link.

He took the floor in Panel 2 on the topic “LUNAR HORIZONS: The Economic Implications of Lunar Exploration and Utilization”, together with Nasr Alsahaaf, Gongling Sun and Satoru Kurosu, moderated by Zhao Chenchen. The video is available here: YouTube. In his triple role as CEO, spokesperson for German SMEs and voice from Europe, Dr. Pfeiffer focused on these key messages: The challenges facing space – and here both SMEs and corporations, European countries such as Germany and Romania – as well as a highly ambitious ESA are as immense as the opportunities.

Radically divergent budget lines of the major continental players reinforce the requirements for models of cooperation, as do the different perspectives that politicians in particular adopt: some see mainly risks, while others see opportunities. Exploiting these opportunities largely depends on the availability of the two main factors: industrial infrastructure and people who can leverage synergies between scientific and commercial exploration. An additional boost to cohesion, despite all cultural and political differences, can come above all from global cooperation on projects such as the exploration and colonization of the moon.

It is equally clear, Pfeiffer told the international plenary session, that more peace between the peoples of the Earth will ultimately lead to more freedom of action and financial budgets in joint planetary exploration. According to Pfeiffer, UNOOSA must play a leading role in this. There are enough topics: space debris, mining rights, space traffic. According to Pfeiffer, the quality and ability to contribute of the many equipment suppliers from Germany will be able to play an important role in solving all problems.

July 2024

Family & Friends Team Event at HPS Munich

HPS celebrates “Family & Friends”: July 10, 2024 is a special date – we celebrated with the entire HPS workforce and their families and all those many friends of our company according to the motto: Shared joy is double the joy.

Because we at HPS have many reasons to be happy: Since July 1, 2024, our HPS family has grown to a new record level with a total of 93 employees (including 11 freelancers and students) at the Bucharest (HPS Romania), Münchberg (HPtex) and Munich (HPS HQ) locations, and in Munich we have just expanded with a new, large floor in Hofmannstrasse as well as a large assembly area in the basement.

The circle of our friends from joint projects and association activities is huge, many from the Munich area came to visit us today, we were overwhelmed by the large number of surprise guests. Success is best celebrated with “Family & Friends”!

ESA pushing market-driven series production with co-financing of 1.2 million euros

July 2024

ADEO deorbit sail system from HPS

Space-related technologies should be clean and sustainable, because only then access to space will remain possible for future generations. This topic, which is currently a top priority of space policy, has led to a number of technical solutions which are now available on the market, with the ADEO deorbit system from HPS leading the way. Being recognized even by NASA, the ADEO dragsails ensure already before launch that satellites will not turn into space debris at the „end-of-business“. Instead, they re-enter the Earth’s atmosphere.

The European Space Agency ESA, as well as its national counterpart DLR and the Bavarian Ministry of Economic Affairs, has consistently supported the twelve years of development of this product by HPS. The sharp increase in demand from customers, particularly in the CubeSat and SmallSat sector from Europe, but also from North America and even Asia, is driven by the simple fact that both ESA, for European launches, and the FCC, for American launches, now demand on-board systems to be able to deorbit a satellite in just 5 years instead of the previous 25 years. Also SpaceX confirms that no more satellites will be launched without complying to this requirement.

With the ADEO variants “Pico”, “Cube”, “Nano”, “Medium” and “Large”, HPS meets the market demand for all sizes of LEO satellites in orbits between 300 and 900 kilometers. All variants are already in production, with manufacturing at the HPS production sites in Munich (Germany) and Bucharest (Romania) which are closely working together. Nevertheless, HPS and the technical ADEO experts at ESA have identified a number of optimization and expansion opportunities in order to urgently increase the pace of the series production and in response to the increasing price pressure of the New Space scene. The company is now raising the required funds for the implementation of these opportunities in the short term, using co-financing of 1.2 million euros signed by ESA on June 28, 2024.

ESA-Director Dietmar Pilz for Technology, Engineering and Quality in a videocon on July 1st: „my best wishes for this important technology development.“

HPS CEO Ernst K. Pfeiffer: “As a company, we are very pleased about the trust and continuous support from the European Space Agency, and therefore indirectly also from the German Ministry of Economic Affairs. However, this is at least as much a reason for joy for all those who, thanks to its technology programs such as GSTP, would like to see Europe in a leading role in the development of components for space technology and -transport, especially in the commercially so important LEO and MEO supplier market.

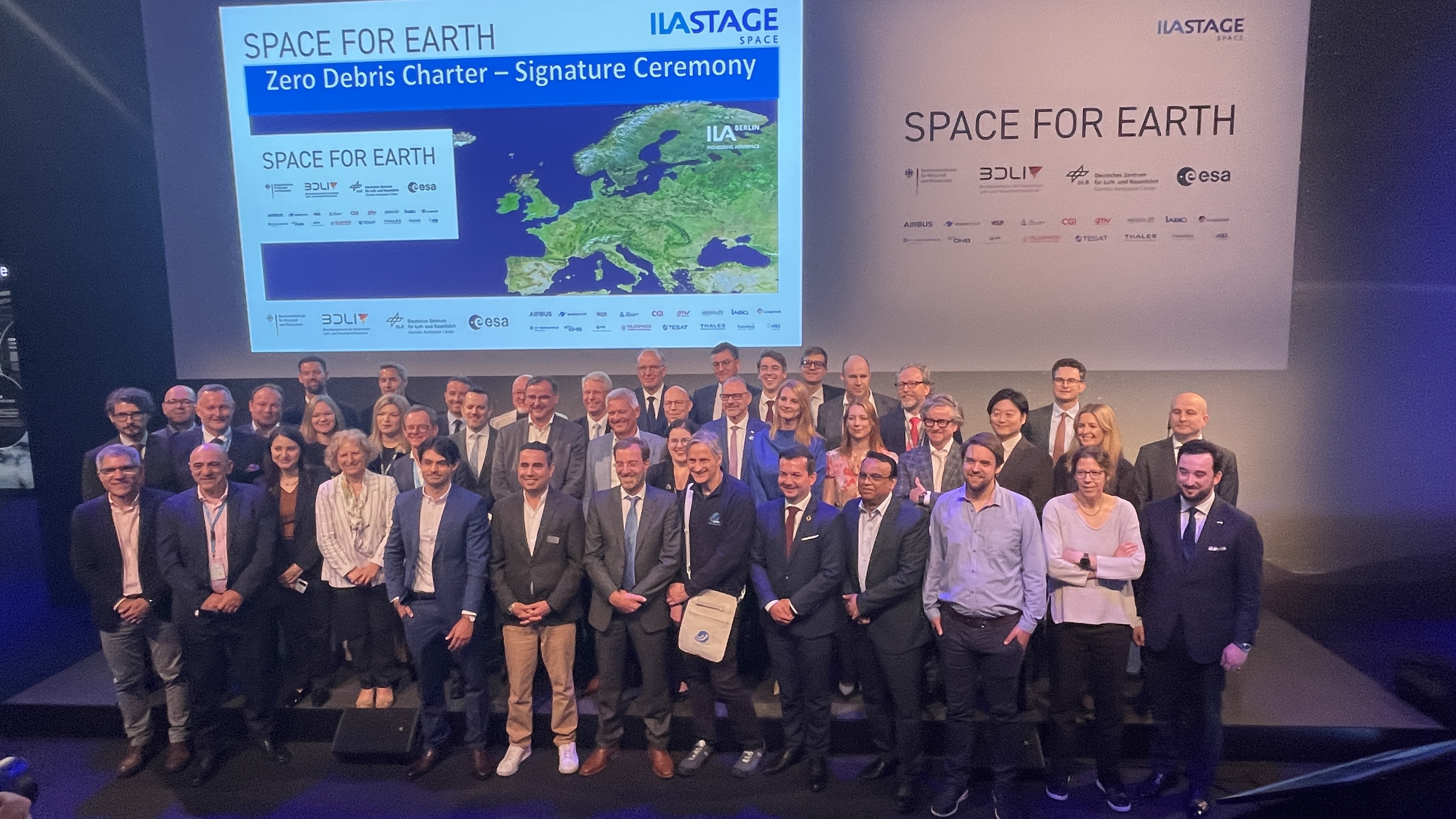

ESA’s priorities here are not only clear, but are also being consistently implemented. One milestone was the recent signing of the Zero Debris Charter in Berlin. The upcoming optimization of series production and the enhancement of our ADEO product portfolio, while maintaining the same level of quality and reliability, will effectively help to face the upcoming peaks in global orders, including those received very late, and thus still enable the launch of these satellites. We shareholders see our own funds, in the 7-digit range over the years, on the one hand as an investment in a strong future for HPS, and on the other hand as our moral obligation to make a contribution to the sustainable use of space.”

HPS Signing of the Zero Debris Charter at ILA on June 6, 2024

June 2024

ESA Leads the Way: Rapid Implementation of the Zero Debris Charter

Sustainability in space travel has also been an issue for the European Space Agency ESA for years. However, only a few months passed between the decision to adopt a Zero Debris Charter and its implementation.

Keynote speaker ESA Director General Josef Aschbacher also saw this as a sign that the time is finally ripe for concrete steps instead of pure symbolism, especially as ESA itself has provided significant impetus for the development of the two main technologies on the way to “Zero Debris”: firstly, ways of removing scrap from space, but above all, equipping satellites with deorbit technology from the outset so that no more waste is produced after the end of the mission.

ADEO Drag Sail: The Key to Sustainable Spaceflight

The ADEO brake sail, which is now available as an entire product family for all sizes of LEO satellites from HPS series production, stands for this. In addition to grants and support from ESA, DLR and Bavaria, HPS CEO Ernst K. Pfeiffer also invested a lot of the company’s own money in the project, always firmly convinced that the hour of ADEO would come sooner or later – and if a little later, then all the more powerfully.

It was exactly the same when, in mid-2023, the ESA set the new rule of a deorbit maximum of 5 years for ESA-funded missions instead of the previous 25 years, and, accordingly, LEO satellites without ADEO (or similar) will no longer be launched at all from October 2024, as SpaceX, for example, makes clear in its conditions of carriage in accordance with FCC regulations.

Historic Moment: 12 Nations Sign the Zero Debris Charter

The Charter was signed in Brussels on May 22 by 12 countries, including Germany. Since then, over 100 organizations, companies and entrepreneurs have been waiting for their cue to sign.

The ILA 2024 marks a very important stage on this path towards the sustainability of European space travel and sets an example for companies on other continents.

January 2024

KEAN II passes the acid test at the University of the German Armed Forces and in the field

KEAN, the integrated deployable lightweight manpack complete antenna from HPS and its development partners, has taken a decisive step forward in the KEAN II (Second Generation) version: it passed the tough link test at the University of the German Armed Forces in Munich in December 2023 and the handling test in the field. This brings the goal of the joint HPS project much closer: the development of a complete system for bidirectional satellite communication based on preliminary developments already carried out by HPS and these specifications:

- Conformance to satellite operators (e.g. EUTELSAT, INTELSAT)

- Ku-band, 1.2 m diameter, also X- and Ka-band capable

- Including communication system, electronics, battery, tripod, backpack carrying system

- Total weight <20 kg

- Commissioning in under 15 minutes from backpack transport to satellite link

- Innovative, cybernetic folding mechanism based on the opening and closing of flowers

- Design and definition of components and production processes suitable for series production for a rapid transition to series production in large quantities.

Partners in the project are:

- The system supplier MTEX (Wiesbaden) with a focus on ground stations and electronics.

- The start-up Blackwave (Ottobrunn) with the economical series production of complex carbon components.

- The Chair of Carbon Composites (LCC) at the Technical University of Munich for the design of innovative extremely lightweight reflector fins.

- The Bundeswehr University for defining the user requirements and carrying out the antenna link tests with satellites.

The additional antenna deployment tests in rough terrain in the Bavarian Alps were closely monitored from the air by camera-guided drones; they provided complete documentation of the challenges, but also of the success of these tests. Videos are available at the YouTube Channel. Particular attention was paid to features and elements such as these during the tests:

- Wearing comfort off-road (walking and running) with different body sizes

- Assembly and disassembly over time in rough terrain (bushes, gravel, snow)

- Speed of unfolding and folding

- Handling by untrained test persons

- Wind load compatibility

- Handling in cold conditions (requirement: from -30o C to +55 o C)

- Robust construction

The target markets for applications of this completely new technology for communication via satellite, especially on X-, Ku- and Ka-band, cover all three conceivable directions:

- commercial, such as journalistic reporting from rough terrain

- institutional, such as rescue and disaster relief operations

- military, such as for small special forces operating independently of vehicles without a direct connection to the base of fully equipped large units

- scalable up to 3.6 m, also for mobile transportation on small vehicles.

Beyond the technical successes, KEAN II is currently growing wings from a completely different direction: the European Commission’s major IRIS2 project to establish absolutely secure connectivity via a dedicated multi-orbit constellation of several hundred satellites from LEO to GEO is giving a significant boost to all those application scenarios that were previously considered to have only seen very hesitant development due to their dependence on non-European constellations and individual satellites. This applies in particular to the institutional and military markets, both of which are now growing into larger dimensions.

The last stage of development was funded by the German Aerospace Center (DLR) as part of the ILKA project with funds from the Federal Ministry of Economics and Climate on the basis of a decision taken by the German Bundestag.

The magic triangle: competence – quality – capacity

January 2024

Servicing Europe´s ambitions in space from Romania

In less than a blink of an eye, it will be a full decade that Romania´s leading space-SME “High Performance Structures Inovatie si Desvoltare S.R.L.” will look back to the beginnings of the company´s history in 2016, when it opened its office in Bucharest. Founded to meet the needs for additional capacities of HPS Munich, HPS RO quickly developed ttowards becoming one of the most renowned full-service spacetech-companies from ESA-member states in the Eastern Europe.

Just one question to managing director Astrid Draguleanu:

From the very beginnings and through the years, you have been in the position to significantly participate in shaping and guiding the company´s development. From your perspective, which factors are the ones that keep pushing HPS forward on the road of success?

From our point of view, there are three rock solid pillars the company´s success rests on.

Number one: COMPETENCE. HPS RO is an engineering company, with driven top engineers trained in the sectors of engineering, development, assembly, secondary and tertiary structures, thermal and RF-components, mechanical ground support equipments. In addition, we have managed to combine forces with commercial and institutional suppliers and partners, contributing competencies in special segments like precision manufacturing, welding, process verification, and assembly tests. So when one´s looking for a onestop source of competence in Romania and ESA´s Eastern European presence as a whole, they will sure find it in Bucharest.

Number two: QUALITY. In the Space Industry, quality is attributed to those who manage to comply to the specific standards and building up an immaculate heritage of successful steps on the ladder to the top. HPS RO proved that it has taken those steps, and done it with at an amazing pace: In the past eight years we have contributed to a total of twelve Space Missions so far. To get an idea of what´s behind that, let us just take a more detailed look at the contributions we´ve made in the area of mechanical ground handling and support equipment, MGSE:

- Purge Equipment for the JUICE Spacecraft on behalf of Airbus Germany

- Satellite Vertical Integration Stand for the Biomass-Mission, Airbus U.K.

- Instrument & Optical Bench Lfting Frames, Copernicus Chime Mission, OHB

- Instrument Turntable Support Stand and Instrument Turntable, Instrument Alignment Trolley, Instrument Lifting Device, Multipurpose Adapter, Vibration Test Adapter, Vertical Integration Stand, Instrument Support Structure and Instrument Mass Dummy for the METOP mission, Airbus Germany

- Satellite Hoisting Device, transport containers, various adaptors – in total 14 MGSE-assemblies for Copernicus CIMR by HPS Germany.

Number three: CAPACITY. From the very beginning, it has been absolutely clear to all of us that HPS RO has a great future, by focusing on its character as a company with high professional level and not afraid of hard work. That is why building and keeping up capacities is yet another pillar we use. Take, for example, the fact that, before having even one contract to justify the expenditures, we started out from the beginning with production facilities, giving room the even the most ambitious dreams of development. And it proved to be the golden path to go: Apart from servicing all current needs of customers, we were most happy to have the capacities for starting out the series production of the HPS Satellite Dragsail product family “ADEO”, when the winds of change reached politics and deorbit technology became a legal prerequisite to let a satellite go into space to begin with. Of course, we apply this philosophy of “growth follows capacity” also to our HR-management. Today we employ a total of 20 engineers in Bucharest, growing in numbers at top speed. We are convinced that the reason for the whole success story is the delicate balance we have learned to keep in our magical triangle of COMPETENCE, QUALITY, and CAPACITY.”

The Munich-based space-tech company HPS had this development in mind more than ten years ago, when no one else was really thinking about ways to avoid space debris. With great support from the space agencies ESA and DLR, the DLR institutes in Bremen and Braunschweig, the companies DSI, Bremen, and formerly HTS, Coswig, plus a seven-digit-investment of HPS, the company´s highly committed young team of experts has created an entire product family under the generic name ADEO, from the smallest versions ADEO-P (Pico), ADEO-C (Cube) and ADEO-N(Nano), ADEO-M (Medium) and the latest member of the group, ADEO-L (Large). The development master plan not only extends even further to possible ADEO variants with up to 100 square meters of braking surface, but also leaves enough room for derivatives with completely different applications, such as the monitoring of space debris smaller than1 cm directly in space.

In its largest flight-ready version to date, L1, ADEO has a take-off weight of 10 kg at dimensions of 43 cm x 43 cm x 25 cm; in contrast to the smaller versions, this unit also requires its own power supply for motor-controlled deployment of the masts and sails. ADEO-L1 generally fits perfectly on satellites up to the 1,500 kilo class.

In the first quarter of next year, ADEO-L1 will be integrated onto a satellite of the Belgian company Redwire for its first test flight at the end of 2024/beginning of 2025 as part of a EU program, while the versions ADEO-N1 and ADEO-N2 have already passed their baptism of fire in space. Approaching the fiery finale is currently ADEO-N2, deployed in December 2022. Since then, it has already lowered its satellite from an orbital altitude of 510 km to 460 kilometers in only 12 months without the aid of any fuel or attitude control. Expected “arrival” in a completely burnt-up state: mid2025 – and thus even around five times faster than without sails and twice as fast as prescribed.

ADEO-L1 will master this path of final in-orbit verification just as safely, company boss Dr.-Ing. Ernst K. Pfeiffer is certain. As with the other versions, it will then go straight into series production for which the company has special production facilities at its Munich and Bucharest sites.

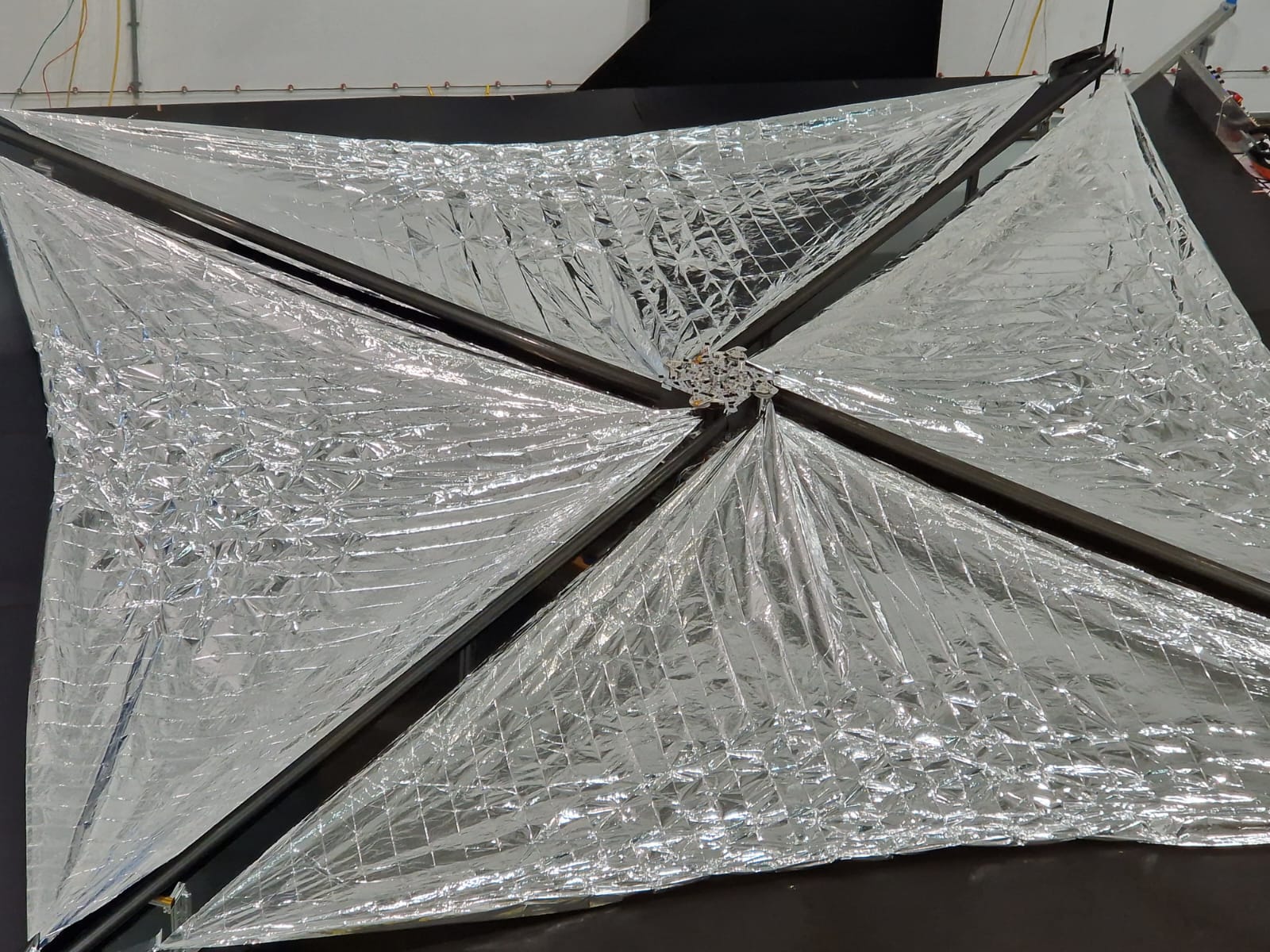

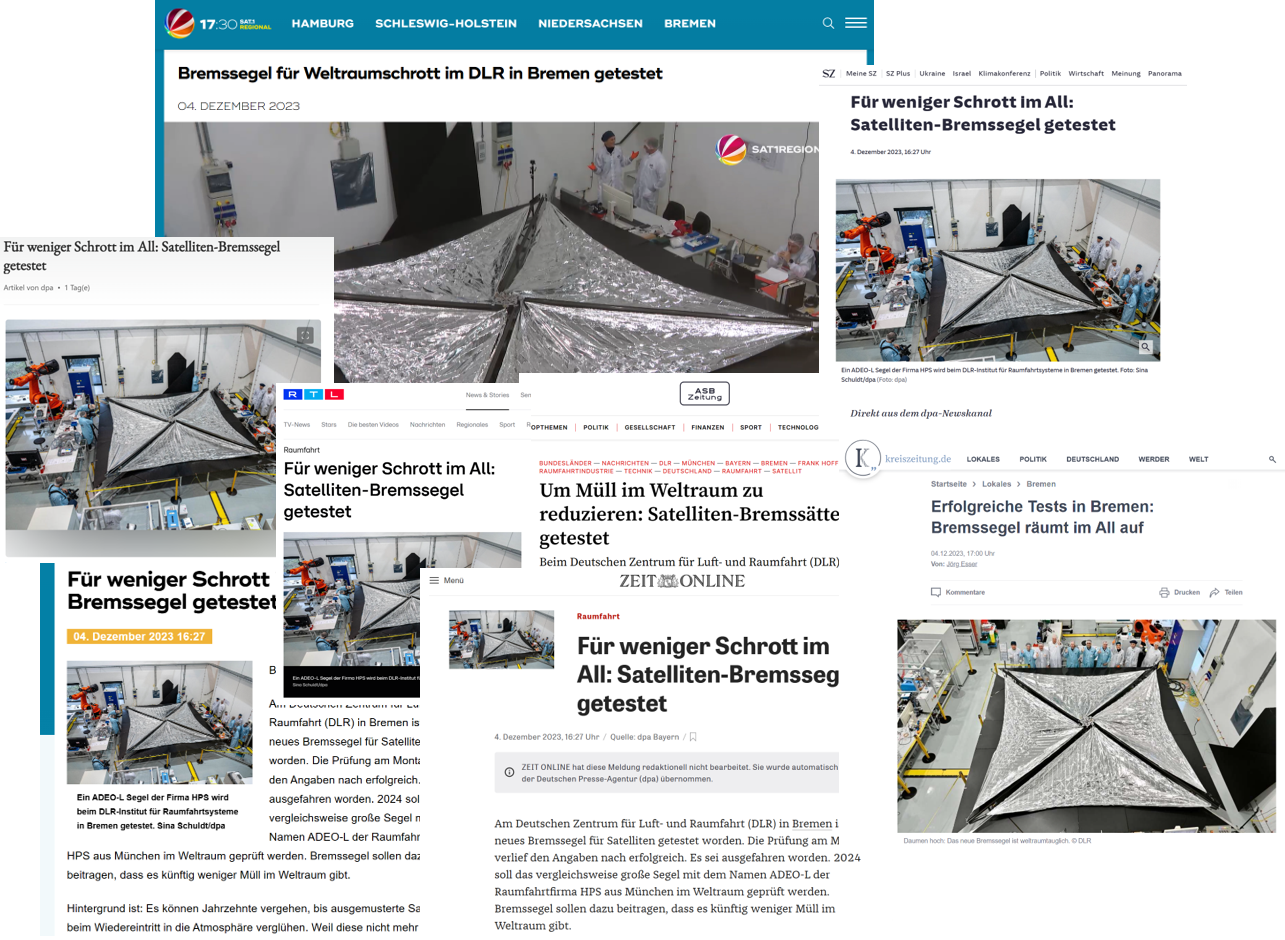

ADEO L1 “ready for lift-off”: World’s largest operational brake sail for the disposal of space debris successfully tested

Dezember 2023

ADEO L1 “ready for lift-off”: World’s largest operational brake sail for the disposal of space debris successfully tested

HPS completes the ADEO sail fleet with its first largest version under the version named L1. Its 25 square meters of sail area unfolded successfully deployed on Monday, 4th of December 2023 in a final ground test after a complete completed PFM qualification campaign. This included vibration tests in all axes as well as tests under thermal vacuum, including hot and cold firing tests (tests to verify the deployment release mechanisms under extreme temperatures). The tests were carried out under responsibility of HPS Munich at the facilities of the DLR Institute of Space Systems in Bremen – a prime example of cooperation between industry and research & development. This final and most important test enjoyed great interest from the media (including SAT1, RTL, NTV, DPA) covering the 20-minute deflation process and interviewing the enthusiastic project team of HPS and DLR. Links to the articles and television videos can be found HERE.

This test is also a success of ESA’s GSTP program, which significantly supported the development of ADEO-L1 financially and technically. Technology programs in general are essential for independent SMEs in the space industry and their products on the way to market readiness and worldwide series sales.

The ADEO brake sails deploy after the end of the satellite’s mission and brace themselves against the resistance of the atmosphere that still prevails in orbits up to an altitude of just under one thousand kilometers. This deployment immediately leads to a drastic reduction of the speed of the satellite and the entire package sets off on its accelerated descent towards the earth’s atmosphere, where it then burns up in the frictional heat of up to two thousand degrees Celsius. The entire return process takes even significantly less time than the latest guidelines prescribe. Until recently, the process could take up to twenty-five years, while it must now be completed within five years. And, to ensure that operators follow the rules, launch service providers such as SpaceX no longer even take satellites into space if they are not equipped with the appropriate return technology from the outset.

The Munich-based space-tech company HPS had this development in mind more than ten years ago, when no one else was really thinking about ways to avoid space debris. With great support from the space agencies ESA and DLR, the DLR institutes in Bremen and Braunschweig, the companies DSI, Bremen, and formerly HTS, Coswig, plus a seven-digit-investment of HPS, the company´s highly committed young team of experts has created an entire product family under the generic name ADEO, from the smallest versions ADEO-P (Pico), ADEO-C (Cube) and ADEO-N(Nano), ADEO-M (Medium) and the latest member of the group, ADEO-L (Large). The development master plan not only extends even further to possible ADEO variants with up to 100 square meters of braking surface, but also leaves enough room for derivatives with completely different applications, such as the monitoring of space debris smaller than1 cm directly in space.

In its largest flight-ready version to date, L1, ADEO has a take-off weight of 10 kg at dimensions of 43 cm x 43 cm x 25 cm; in contrast to the smaller versions, this unit also requires its own power supply for motor-controlled deployment of the masts and sails. ADEO-L1 generally fits perfectly on satellites up to the 1,500 kilo class.

In the first quarter of next year, ADEO-L1 will be integrated onto a satellite of the Belgian company Redwire for its first test flight at the end of 2024/beginning of 2025 as part of a EU program, while the versions ADEO-N1 and ADEO-N2 have already passed their baptism of fire in space. Approaching the fiery finale is currently ADEO-N2, deployed in December 2022. Since then, it has already lowered its satellite from an orbital altitude of 510 km to 460 kilometers in only 12 months without the aid of any fuel or attitude control. Expected “arrival” in a completely burnt-up state: mid2025 – and thus even around five times faster than without sails and twice as fast as prescribed.

ADEO-L1 will master this path of final in-orbit verification just as safely, company boss Dr.-Ing. Ernst K. Pfeiffer is certain. As with the other versions, it will then go straight into series production for which the company has special production facilities at its Munich and Bucharest sites.

HPS wins German government space competition with ADEO deorbit sail

November 2023

Space sails from the ADEO series enable legal launch and disposal of satellites

As part of the National Program for Space and Innovation and based on the decision of the Budget Committee in November 2022, the German Space Agency launched a competition for promising space innovations. The winner can expect a fully organized and financed demonstration flight with launch by 31.12.2025. On Thursday, 23 November 2023, the Federal Government’s Space Coordinator, Dr Anna Christmann, selected Munich-based space technology company HPS as the winner of the competition in the small satellite payload category with its ADEO-Cube space sail version at the 2023 Small Satellite Conference. The ADEO product family is designed as a series with different model types (Pico, Cube, Nano, Medium, Large), with which all satellites from the Cubesats to the larger representatives with 1.5 tons (class “M”) are automatically removed from low Earth orbit (LEO) and disposed of at the end of the mission. This so-called “deorbiting” with the ADEO braking sail not only fulfills, but even undercuts the maximum duration of 5 years that will apply from October 2024 instead of the 25-year guideline that has been in place since the 1960s. Quite simply, this means that no satellite will soon be accepted for launch without special on-board technology, such as the appropriate space sail from HPS’s ADEO series, if it cannot otherwise be legally disposed of. Since SpaceX, for example, as the leading launch service provider, will be introducing this rule from October 2024, it will apply to practically all future satellites, including those that are already in the design and manufacturing phase today.

As HPS CEO Ernst K.Pfeiffer, there is still only one alternative to ADEO, but it “is chemical, expensive and – in the case of a damaged satellite – inoperable”, the passionate aerospace engineer states about the market position of the ADEO space sail: “ADEO is currently the cheapest, most reliable and cleanest solution for legal deorbiting on the global market, available in all classes thanks to series production at HPS Bucharest and HPS Munich, and highly competitive in the hotly contested commercial market for satellite technology.We at HPS, especially our development team, are all very pleased that our sustainable technology has been recognized by the Small Satellite Competition at the highest level.”