March 2020

HPS Space News

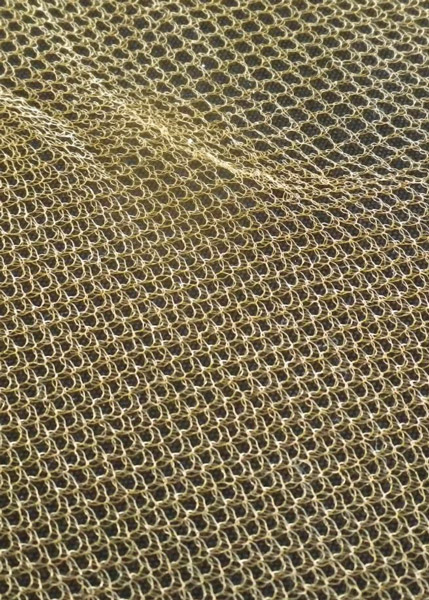

MESH Made in Germany

Technical Textiles from Bavaria for the Worldmarket Space

With the foundation of HPTEX GmbH in equal shares by the Bavarian companies HPS GmbH and Iprotex GmbH & Co KG, a company is being launched that no one else in the space industry has ever had on the cards before: HPS, the European specialist for satellite antennas of all sizes, and Iprotex, the heavyweight for technical textiles on the world market, are joining forces and competences to establish Bavaria and Germany as the centre for metallic high-tech fabrics, the “mesh”, in ordere to serve the international space market.

The HPTEX GmbH joint venture thus aims at a key component of satellite technology for two core applications at the same time: Earth observation and communication.

For both, the mesh functions as a resonance body for reception and transmission of radar and communication data between heaven and earth, for generating images for climate protection and to provide stable communications networks for the earth’s population. The precision of production is measured in micrometers, i.e. ten thousandths of a centimeter, and must achieve an optimum between electrical conductivity and mechanical elasticity homogeneously over reflectors of up to 15m diameter, for frequency bands between L- and Ka-band, and in the medium term also up to V-band. To guarantee this, the two companies behind HPTEX have concentrated development and production technology of the latest generation at the Münchberg site in order to meet the extremely special requirements of the customers.

Initial mission objectives are the pre-development and pre-qualification of a Ka-band mesh for “CIMR”, a satellite of the EU Commission’s latest flagship fleet Copernicus for the observation and measurement of climatically relevant developments in the Arctic, and a series of small satellite antennas from the commercial NewSpace sector. In the area of research and development, HPTEX works closely with the leading institutions in the region, the Fraunhofer Münchberg and the University of Hof.

For a transitional period of a few weeks, direct sales of the products will continue to be handled by HPS in Munich until the new staffing levels have been established to allow HPTEX to take over.

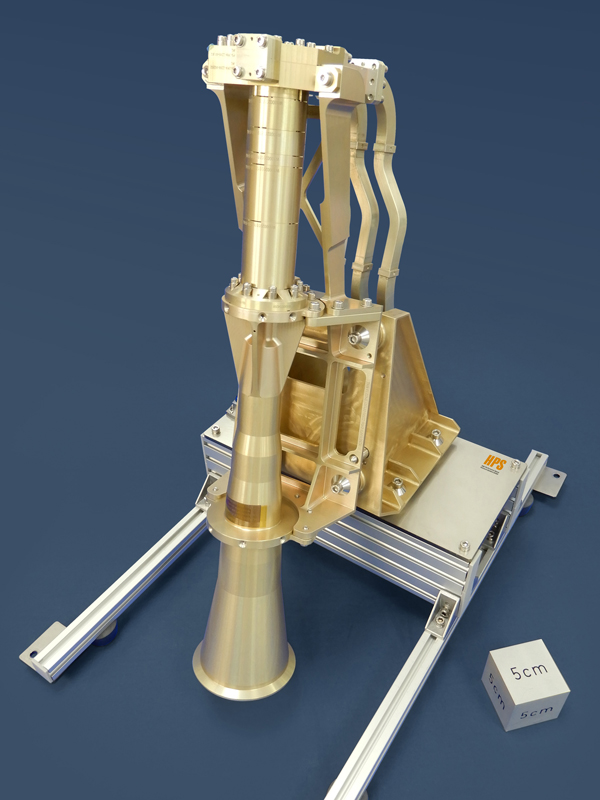

Flight model of the H2NBA Feed Assembly successfully completes RF test

March 2020

The „Feed Assembly” as an essential component in the RF signal transmit/receive-chain of the Ka-band North Beam Antenna “H2NBA” for the Heinrich Hertz Mission was successfully assembled in February 2020.

Before the time consuming final surface treatment the assembly was RF-tested in the test laboratory of ADS, Munich Ottobrunn.

Other components of the H2NBA-Antenna such as the “CFRP Reflector Assembly” as well as the mechanisms for antenna deployment and pointing and the fixation during launch are already nearing completion. The final integration and all tests at antenna level will take place according to schedule between July and October 2020.

October 2020

HPS antenna for space mission Heinrich Hertz passes meticulous test

With the launch of the Heinrich Hertz satellite in 2023, Germany will once again be flying the black-red-golden flag in satellite telecommunications – twenty years after the DFS Kopernikus mission completed in 2002 – on the innovative “Small Geo” platform from OHB 36,000 kilometers above the earth. On board Heinrich Hertz are some 20 experiments on communications, antenna and satellite technology being conducted by institutes and companies to thoroughly test new satellite communications technologies for their suitability under the extreme conditions of space. Heinrich Hertz is nothing more and nothing less than the decisive step in the German space strategy to regain a foothold in the field of telecommunications with system capability of its own industry – on satellite and equipment level.

Beyond the previous design standard of installing only the receiving, forwarding and transmitting technology on a communications satellite, Heinrich Hertz has onboard processors for direct information processing and, in addition, for flexible readjustment of the satellite itself during operation. In addition to scientific mission objectives, the Ministry of Defense and the Ministry of Economics intend to use additional payload capacities for their own communications. And finally, Heinrich Hertz also serves as a relay station for smaller earth-orbiting satellites with a mass of up to 800 kilograms, extending their contact times to around 40 minutes each, thereby considerably increasing the amount of data transmitted.

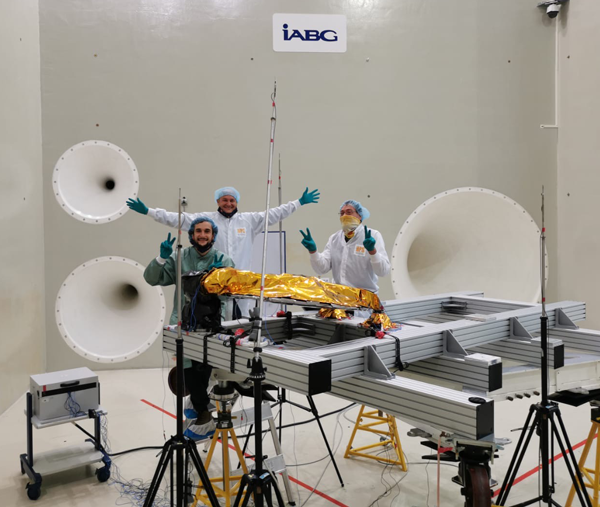

All political and technical ambitions of the project depend crucially on the reliability of the invisible umbilical cord of data transmission between heaven and earth, satellite and ground station. With the successful test of the laterally deployable H2NBA antenna – the abbreviation stands for “Heinrich Hertz North Beam Antenna” – from the German antenna specialist HPS, this hurdle has now been overcome: The surface measurement of the reflector with laser radar tested 0.04 mm RMS (average deviation) over the entire reflective surface, the unfolding test in the HPS laboratory with 0-g compensation mechanics went off without a hitch; the antenna also passed vibration tests in all axes at the testing company IABG, Munich, under the extreme load of 25 times the acceleration due to gravity and acoustic tests up to 142.5 dB – this corresponds to the volume of a launching rocket.

The CFRP-based antenna including reflector, feed and tower, hold-down-and-release, deployment and pointing mechanisms from HPS or their subcontractors, is extremely lightweight yet dimensionally stable, offers high natural frequency and is suitable not only for the intended data transmission in the high-frequency Ka-band, but also for the even higher frequency band Q/V-band.

Following final on-time thermo-elastic and RF tests, the antenna will then be joined to the satellite in 2021/22 by the main contractor OHB.

HPS CEO Ernst K. Pfeiffer: “I am pleased and delighted with the results of the tests because even after a quarter of a century in space technology, as a passionate engineer you still break into a sweat during the murderous vibration tests at the latest. My respect to our structural engineers, who calculated all this so perfectly in advance and to all my test leaders who worked really persistent and carefully the last month to have a successful test! We are proud to be part of this groundbreaking mission at such a crucial point as specialists for both rigid and large deployable antennas, which we have been able to become thanks to the continuous support of DLR Space Agency and of ESA. After 20 years company history, with now 71 employees at our Munich locations and Bucharest, we stand for the M in SME at the level of the German as well as European space industry.”

Noveber 2020

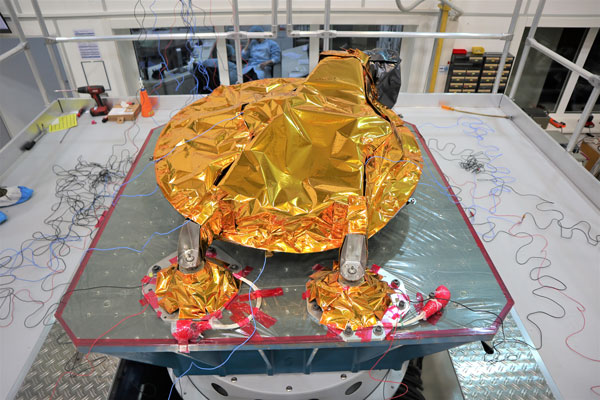

Deployable 5-meter “LEA” antenna starts baptism of fire on the test stand

Punctually three years after the decision of the EU, in November 2017, to place the development of the critical space technology of an antenna that can be deployed in space in the hands of an SME-consortium with 15 companies from seven member states led by the Munich-based antenna specialist HPS, the project celebrated four successful European premieres on November 10th 2020:

- Installation of a 5m deployable reflector of and by LSS GmbH

- First surface accuracy check of this reflector

- First RF (Radio-Frequency) test of the complete reflector

- First successful application of highly innovative RF-test technology.

The space programs of ESA and the EU reflect the enormous importance of research and application projects from earth observation and telecommunications for the development of independent ecological and economic positions in politics and business.

The first prerequisite for this is the unrestricted availability of the communication capabilities and image data collection of corresponding satellites – and thus of their antennas. In order to save weight and storage, more and more deployable constructions are being planned here, which have so far only been available in the USA. Europe has now put a stop to this dependence.

The 5-meter antenna (now under test) under the designation “LEA-X5”, is intended for X-band communication. The surface accuracy of the reflector, developed since the beginning and assembled now by LSS for many months, was measured by HPS with laser radar technology from NIKON. The element of the antenna responsible for the reflection, the gold plated metal mesh under the designation “ESM-European Space MESH”, is also compatible with the higher Ku-band. It is manufactured by HPTEX, a joint venture of HPS and Iprotex in cooperation with Fraunhofer in Münchberg. The high-precision carbon fiber struts were developed by the Portuguese company “FHP”, while unfolding electronics were supplied by the Schwetzingen Company “von Hoerner & Sulger”.

Also the adherence to all interlinked corridors of the participants all over Europe to realize this early test date was successful despite considerable organizational complications caused by the Covid-19 pandemic: “operative flexibility in teamworking, technical genius and the unconditional will to succeed – these are the decisive factors especially in these times. And the WeLEA example shows once again: These are medium-sized companies,” says HPS CEO Pfeiffer. And the CEO of LSS, Leri Datashvili adds: “it has been a very hard work of the LSS team after having collected all the needed components and materials from partners to have designed and built a 5 m large deployable reflector in a very short time reaching the high quality of the RF surface shape, which is now ready for the RF tests”

Now the reflector will be characterized in several frequency ranges (C to Ka-Band) from Airbus over the next 3 weeks in Ottobrunn. Special ground support mechanisms from the Portuguese company INEGI ensure that the reflector is positioned horizontally. The prediction of the antenna performance was carried out by the Danish company TICRA with the help of their special RF software GRASP, with geometrical data from LSS simulations.

In the next step, not only the reflector, also the deployable arm of the antenna will be tested environmentally at INTA in Spain; the focus will be on compliance with vibration, shock and thermal vacuum requirements. Beginning next year intensive deployment tests will follow finally. The entire test campaign will be concluded with PFM (proto-flight model) status in March 2021.

In parallel, WeLEA is already working on an 8-meter Ka-band capable engineering model “LEA-K8r” (reflector and arm) in contract to ESA, as preparation for the technical realization of the polar cap mission CIMR (Copernicus Imaging Microwave Radiometer), which will help Europe to gain its own and politically unbiased picture of the status of climate change. The first deployment tests are planned here for the first quarter 2021.

About WeLEA:

The European SME dominated „WeLEA“-SME-consortium consists of the following European space companies: HPS (prime contractor, DE), LSS (main partner for the reflector, DE), RUAG (DE), FHP (PT), vH&S (DE), Luma (SE), Invent (DE), HPtex (DE), ARQUIMEA (SP), etamax (DE), TICRA (DK), WSS (DE), Inegi (PT), INTA (SP), ONERA (FR). The consortium is strengthened in the H2020-LEA-X5 project on system- and test-side by OHB (DE), TAS (FR) and Airbus (DE).

December 2020

ESA and Thales Alenia Space Italy (TAS-I) authorize HPS to develop the large deployable reflector subsystem “LEA” for the Copernicus mission CIMR

It is official today, 02.12.2020: Europe is going to develop a new independent technology in the European space sector. Thales Alenia Space Italy has been selected by ESA and the European Commission as the Satellite Prime for the Copernicus mission CIMR contract. At the same time, HPS Germany, as leader of an SME-oriented consortium of 15 companies from seven countries (main partners are LSS, vonHoerner&Sulger and RUAG), were selected to develop the “Large Deployable Reflector Subsystem” (LDRS) called “LEA-K8r”. This large, 8-meter diameter reflector will be deployed in space and rotates about a non-symmetrical axis: a world first! Today, with this contract signature, HPS and the European consortium have been authorized to start the development with the phases B2/C/D.

The CIMR-mission, in the context of the Copernicus Earth Observation Programs of the European Commission, provides a significant contribution to the „Integrated European Policy for the Arctic“, whose objective is an improved understanding of the effects of climate change, especially in the Arctic region, and thus will establish key requirements for the Arctic communities. The CIMR-mission will provide improved continuity (sub-daily) in the monitoring of floating sea ice in terms of spatial and temporal resolution. In addition, the instruments will provide global coverage of sea surface temperature measurements, but with a specific focus on the Polar Regions.

Authorized was now the first tranche with 23.0 MioEuro for Phase B2, with an HPS-share of 7.1 MioEuro for two years. In total, the Phase B2/C/D/FM2 contract amounts to 110 Mio Euro until the PFM Satellite launches in 2027 and until the delivery of the FM2 LEA-reflector-subsystems in 2028. The share of HPS Germany values to 26 Mio Euro, which results in an average of 3.2 MioEuro per year, and which assures 15-20 high quality jobs.

HPS CEO Ernst K. Pfeiffer commented: “We are all very pleased to be able to make an active contribution to European non-dependence in an area of critical technology as a subcontractor to TAS-I, and to be able to assume global technology leadership with the innovation of an unprecedented rotating 8m Ka-band reflector subsystem in our portfolio. On behalf of the WeLEA-consortium, I would like to thank all those in Germany and throughout Europe who have supported our ten-year journey to this strategically, politically and technically magnificent position.”

The first phase, B2, includes the detailed design of an EQM. Central to this effort is an intensive breadboard test program, which will raise the few remaining critical elements of LEA to Technology Readiness Level (TRL) 5 within 6 months. As an example, a Ka-band mesh, the “European Space Mesh”, is being developed and produced by the new HPS/IPROTEX joint-venture “HPTEX” along with cooperation from Frauenhofer ISC, in Upper Franconia. Since this metal mesh needs to have an optimal design with respect to electromagnetic wave reflection and mechanical stretch parameters, intensive parameter studies are currently being undertaken. Promising initial results have already been achieved in pre-development.

And our next goals are already in sight: Hydroterra, ESA’s EE10 Candidate Mission which requires a deployable reflector of at least 7 meters in diameter; SENTINEL-1 NG Mission, requiring a single large reflector; and a Ka-Band Internet Broadband mission with 5-metre reflectors.

In addition to large deployable reflector subsystems, the main product lines of the HPS portfolio are classic 1-2 meter reflector antennas for science missions (e.g. Euclid & HERA) and telecommunication missions (e.g. Heinrich Hertz), as well as the world’s only operational product series of serially-manufactured satellite-de-orbit systems under the brand name “ADEO” for decommissioned satellites. By the end of 2021, the HPS Group, consisting of HPS Germany, HPS Romania and HPtex, will grow at least up to 100 employees.

December 2020

… and the world watches via an HPS antenna!

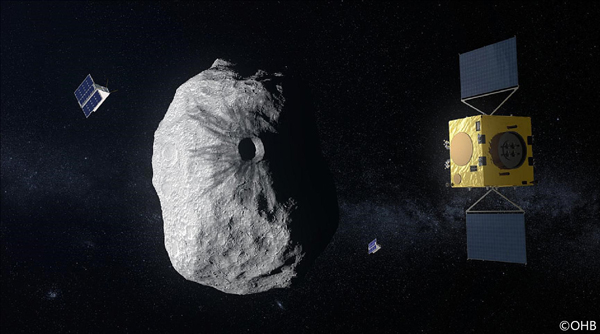

As is well known, the ESA Council of Ministers Conference 2019 has brought a major “jolt” to the German space industry – which German President Herzog had called for as early as 1997 – and a “jolt” that will travel around the world as the moon landing once did! With HERA, Europe is participating in the development of the first Earth defence mission against asteroid aggressors from space. USA is preparing the second satellite. And just like the moon landing more than half a century ago, this project will capture the attention of people all over the world with its images! HERA will transmit these images from well over ten million miles away starting in 2027. Just before Christmas 2020 TAS-ES/OHB contracted HPS now for Phase 1 of the antenna development.

A central element of the HERA satellite is the X-Band antenna subsystem from the German antenna specialist, HPS (Munich). A complete 1.2-meter diameter antenna will be made of highly stable Carbon Fibre, with an extremely low weight, high Eigenfrequency, and good reflectivity. For HPS, the experience gained from its major antenna projects, such as Euclid (ESA, direct customer TAS-SP) and Heinrich-Hertz (DLR, direct customers TESAT/OHB), has created a well-known and proven technology background. This is a major advantage for a mission whose launch date is unalterably fixed in 2024, leaving only 22 months from Kick-off until the required delivery date of the antenna in October 2022.

On 15.09.2020, ESA signed the HERA satellite Prime Contract with OHB-Bremen.

For this mission, Thales Alenia Space Spain (TAS-SP) is responsible for the entire Communication Subsystem and will be the direct customer for HPS GmbH. HPS will utilize INVENT (Braunschweig) as its main subcontractor for the “Build-to-Print” production of the Main Reflector Dish. HPS´s subsidiary in Romania will support with engineering services and hardware components, e.g., the Secondary Reflector.

On 16.12.2020, HPS received their official “GO!” from TAS-SP for PHASE1. For several months now, the project team has been working on the design in order to safeguard the project schedule.

HPS CEO, Ernst K. Pfeiffer, commented: “We are delighted and honoured by our participation in this historic mission. We are pleased to contribute, not only with our established expertise as antenna specialists, but also with the passion of SMEs, being willing to start immediately with a very highly-motivated team. We will be on time! It is exciting to be part of a process of turning science fiction into a technological reality for the benefit of all mankind. My employees are fired up for this mission, and we are investing our own resources, because HERA will also support HPS’s long-term expansion plans.