CIMR-LDRS: The lighthouse project for non-dependence in European space travel enters the production phase of the qualification model (EQM) as planned

CIMR-LDRS: The lighthouse project for non-dependence in European space travel enters the production phase of the qualification model (EQM) as planned

Long before an unspeakable bloodbath sealed the end of peaceful life in Eastern Europe in 2022, the demand for technological “non-dependence” had already conquered a top position among the strategic priorities in German and European space travel. The focus was particularly on large reflector antennas that could be deployed in space, suitable for missions of all kinds.

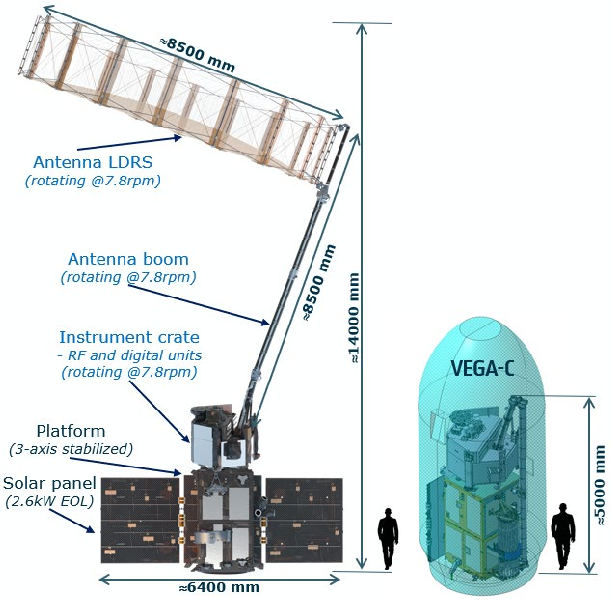

The history of this German technology for Europe began more than a decade ago with SCALABE, a technology development funded by ESA, and SMERALDA (SME’s Radar and Large Deployable Antenna), a study funded by the German Space Agency with significant participation by antenna specialist HPS GmbH. Through further technical chapters of successful concretization of the goal with significant support from ESA and the EU, the Munich-based company finally led a consortium of mostly medium-sized partners from eight countries to the spectacular win of the 115 million euro contract from Prime`sThalesAlenia Space (TAS) for “CIMR LDRS” (Large Deployable Reflector Subsystem) in 2020: the world’s largest rotating deployable reflector antenna construction for the EU’s Copernicus Imaging Microwave Radiometer (CIMR) lighthouse project for observing land, ice and oceans, particularly the Arctic, from space under the management of the European Space Agency (ESA). The LDR subsystem consists of a reflector, arm, deconvolution electronics, cabling, various hold-down mechanisms and thermal hardware.

After a long design phase and intensive iteration with the direct customer TAS in Rome and the end customer ESA, the go-ahead was given in phase C/D with the completion of the first so-called “Manufacturing Readiness Review” for the construction and testing of a qualification model (Engineering Qualification Model, EQM). In these days of spring 2025, HPS has now finally entered the intensive phase of manufacturing the EQM.

Challenges on the way to new shores

The technical challenges were and are immense, as the goal is nothing less than a deployable reflector construct for high frequencies (Ka-band) with a diameter of eight meters on an equally deployable eight-meter-long arm that rotates around its own axis eight times per minute in orbit. This results in extreme requirements such as an RMS (Root Mean Square) value for the surface accuracy, which must be much smaller than 1/10 mm over the entire 50 m² reflector surface, or a maximum permissible deviation of the 8 m distant arm tip of just 10 mm from the nominal value, including vibrations, centrifugal force and thermal deformations.

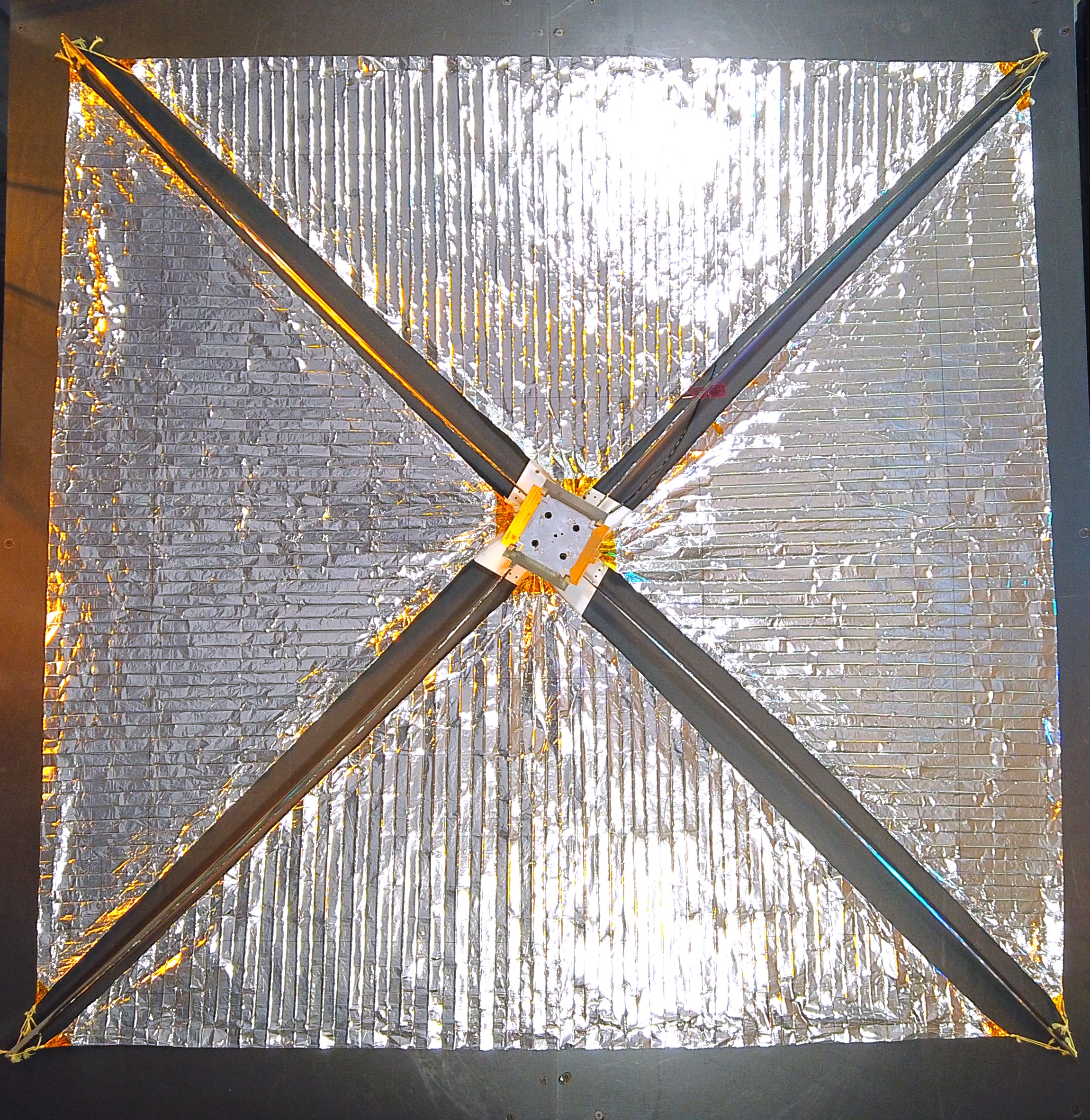

The challenges of managing the various aspects of the project were and are no less demanding. The program management of the CIMR team from ESA and TAS has played a prominent role from the outset, while HPS GmbH, known for its heritage in institutional, military and commercial antenna construction – in addition to its own development work at arm and subsystem level – is responsible for managing the consortium of around a dozen SMEs, including such outstanding innovation drivers as Munich-based LSS GmbH for the deployable reflector assembly (DRA), based on a highly successful, long-standing development partnership. The lightweight carbon struts for the DRA come from the former Portuguese HPS subsidiary and now FHP, INVENT GmbH contributes the carbon fiber-reinforced tubes for the 8-meter deployable support arm (DAA), NanoSpace Switzerland develops and produces the high-precision yet stable, motor-driven joints of the arm, HPS Romania and INEGI Portugal the constructions for ground tests and transports (“MGSE”). In addition, HPS is responsible for providing the central element for the deployable reflector: the measurably best Ka-band MESH from HPtex that is available to buy in a 9m x 9m size – and, as a “made in Germany” product, transforms European non-dependence from vision to reality. Until then, a MESH in such dimensions had only been available in American production. Originally planned as an essential element of the German-European supply chain for CIMR, the joint venture HPTex GmbH (JV of Iprotex GmbH & Co. KG and HPS GmbH), founded in 2020, now sells its mesh products worldwide, especially in Asian and continental American countries. The EQM mesh for CIMR recently came out of HPtex production.

The most important components (DAA and DRA) will be ready by the end of the year, and the series of tests will begin early in 2026.

“If you want to be ahead, you shouldn’t be afraid of the unknown” (Ernst K. Pfeiffer)

When CIMR sets off on its mission in 2029 on board a Vega C in a sun-synchronous orbit to observe ice sheets and snow, among other things, from dawn to dusk, Europe will not only benefit from the knowledge gained from the project, but also from the certainty of having mastered the step towards technological LDRS independence. LDRS are also products for a range of military applications that can contribute to an increased defense capability, especially in these years. HPS CEO Ernst K. Pfeiffer sees this as a milestone that goes far beyond the immediate success of the project: “This space project is clear proof that the mentality of all those involved in the project – both industry and institutions – is completely different to the risk aversion that the public normally attributes to Germany in particular, and to some extent also to ESA. Not being afraid of the unknown is the first key to success. Way up front is where it´s getting dark. Especially in space. But not only there.”

New ESA Technology Activity for HPS – Project MANT

Pushing the limits of what’s possible in CubeSat technology – for science, for Earth, for the future

We are thrilled to announce that HPS GmbH has been awarded a new Technology Activity by the European Space Agency (ESA)! The contract signature has been taken place on 08.04.2025.

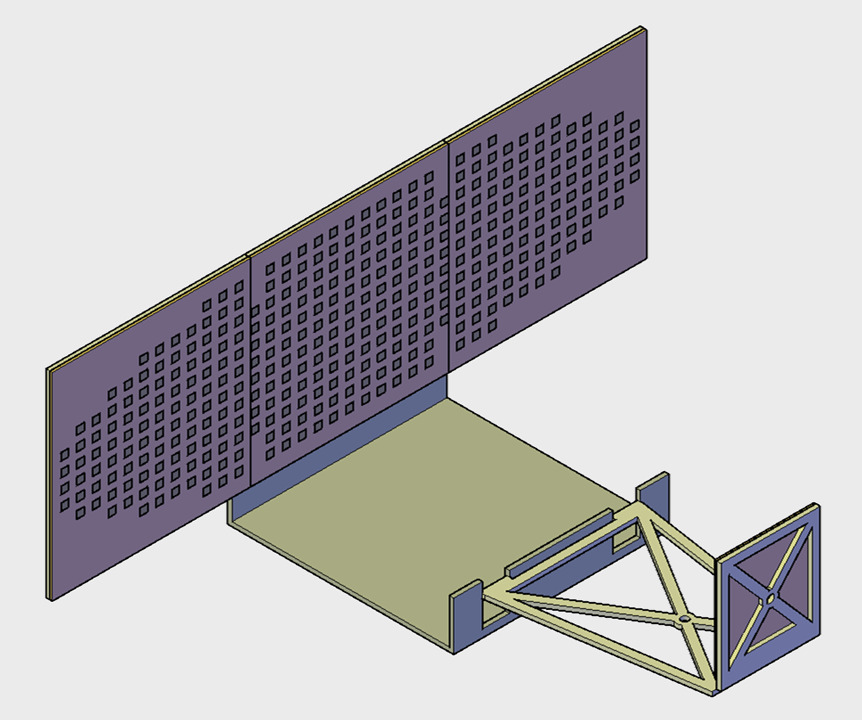

In this groundbreaking GSTP-project, we will develop a cutting-edge CubeSat deployable ArrayAntenna in collaboration with our esteemed partners at Fraunhofer-Gesellschaft (IIS, Germany). This innovative technology, known as MANT (Miniaturized Deployable Antenna for Small and Nanosatellites), will reach TRL6 by the end of the project, marking a significant advancement for the capabilities of small and nanosatellites focussed to civil Earth Observation applications, which always would enable also “Dual Use”. The project is fully funded with a budget of 750,000 euros and will run for two years.

We are excited to contribute to the next generation of satellite technology, advancing small satellite communication with more efficient, compact, and powerful solutions. Stay tuned for updates such as for detailed geometries (in stowed configuration: less than 1U), frequencies and interfaces, as we never stop working towards transforming space technology!

Next Milestone: Requirements Review by end of May.

Cubesat-UDAN by HPS: CDR successfully completed – a major milestone for Europe’s disruptive antenna technology

Cubesat-UDAN: CDR successfully completed – a major milestone for Europe’s disruptive antenna technology

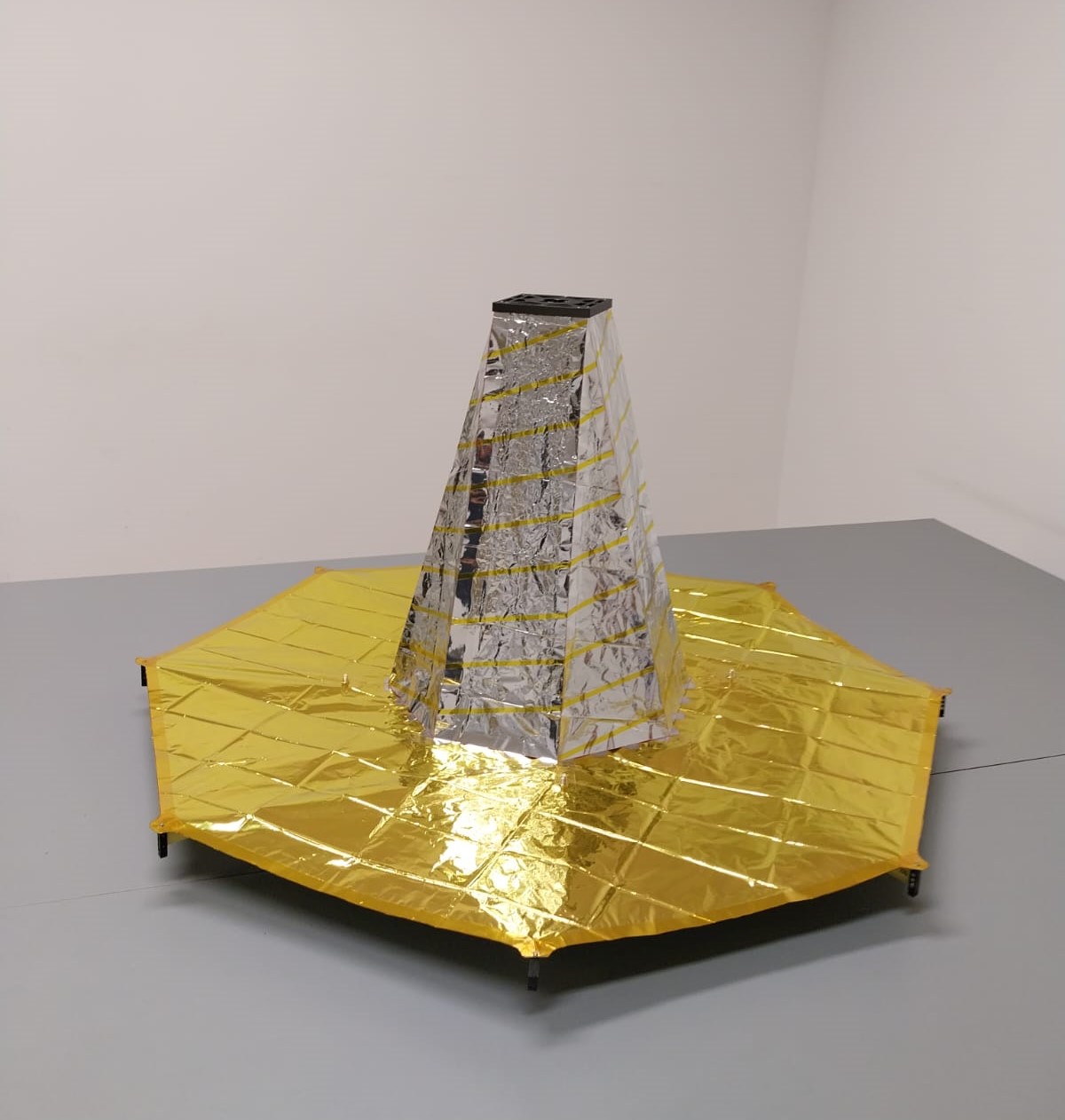

NewSpace relies primarily on small satellites. However, their efficiency is primarily based on antenna performance: the smaller the satellite, the lower the antenna performance and the more expensive it is to technically compensate for this on the ground. The solution from HPS Munich and its Romanian subsidiary in Bucharest: an antenna that can be deployed outside the satellite in the form of a 50 cm high conical quadruple helix and 90 cm diameter ground plane with the additional advantage that it can be scaled to even lower or higher frequencies than the planned bandwidth of between 410 and 460 Mhz but always keeping a gain above 10 dBi. Stowed together for the launch phase, the antenna package is only 10x10x15 cm in size.

ESA was convinced and awarded the development contract in 2018 within its ARTES program to the German specialist for deployable antennas, HPS GmbH in Munich and its Romanian subsidiary HPS S.R.L., Bucharest. In the meantime, the German Space Agency at DLR has provided further ARTES funding to maximize efficient development.

We are delighted that the next major milestone has also been passed with flying colors: the punctual completion of the CDR phase in March 2025. This will now be followed by the production of the engineering model in the second and third quarters and then the test campaign; the contract ends in the fourth quarter of 2025. HPS CEO Ernst K. Pfeiffer comments “With this project completion, HPS will raise UDAN’s maturity level to TRL 6 and then finally to TRL 9 with a planned in-orbit demonstration (IOD). This means nothing less than clear the way for the latest generation of antenna technology on the commercial NewSpace market!”

A full success: the “Space Day” at HPS

A full success: the “Space Day” at HPS

On March 28, 2025, HPS in Munich opened its doors to space enthusiasts and those who might want to become one – and it was a great success! We welcomed numerous guests who took part in our guided tours, presentations, Q&A sessions and workshops with great interest. We were particularly pleased about the visit of Ministerial Director Dr. Markus Wittmann and MRin Anne Köster from the Bavarian State Ministry of Economic Affairs, who came to get a personal impression of our work in Bavaria (Munich and Münchberg in Upper Franconia).

The entire day was characterized by innovation, thirst for knowledge and enthusiasm for space travel. Our guests were given exclusive insights into our products, expertise, processes, test laboratories and clean rooms. Our experts gave exciting introductions to the world of e.g. satellite communication, earth observation and manned space flight and their space technologies. Our CEO, Dr.-Ing. Ernst K. Pfeiffer, gave a presentation on “Why space travel?” in the early afternoon and in the evening, also providing insights into the latest news in global space travel.

The crowds were large and the curiosity of our visitors was overwhelming – every guided tour and every lecture was followed with great interest.

The consistently positive feedback was particularly pleasing: many participants praised the opportunity to experience space travel up close and learn more about HPS technologies. This great response reinforces our goal of sharing not only our fascination for space but also its necessity for Germany and Europe.

With this success, we are very optimistic about the future and hope that after a few years there will be another nationwide “Space Day” to spread the enthusiasm for space travel together with you!

Many thanks to everyone who took part and made this day possible! See you soon!

HPS congratulates ESA to first results of EUCLID mission

State-of-the-art antenna serving one of the most ambitious missions ever

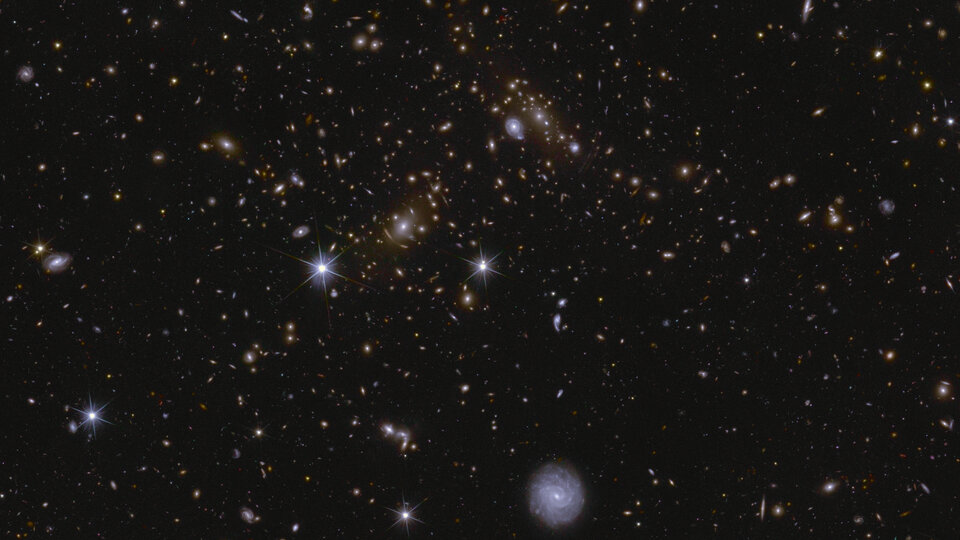

“We are opening up a treasure trove of information for scientists,” said Esa Science Director Carole Mundell. Clotilde Laigle from the “Euclid” consortium described the newly won probe of EUCLID as a “gold mine of data”.

HPS, leading provider of advanced antenna- and reflector-technologies, applauds the European Space Agency ESA to this remarkable progress in the project EUCLID (European Space Agency’s Cosmic Vision: Euclid) which aims to unravel the mysteries of the dark universe and gain insights into the nature of dark matter and dark energy.

EUCLID´s Antenna Reflector Assembly (ARA)” developed by HPS under TAS-contract represents a significant advancement in space communication technology. Its innovative design and advanced features make it an ideal choice for the mission, enabling high-speed data transmission and reception from the spacecraft to Earth and back.

“We are thrilled to contribute significantly to the Euclid mission,” says Ernst K. Pfeiffer, CEO of HPS. “Our cutting-edge technology facilitates seamless communication between the spacecraft and ground stations and allows scientists to unlock and reveal to us on Earth all those mysteries of the dark universe.”

Picture by ESA

Top position in NASA’s technology report extended

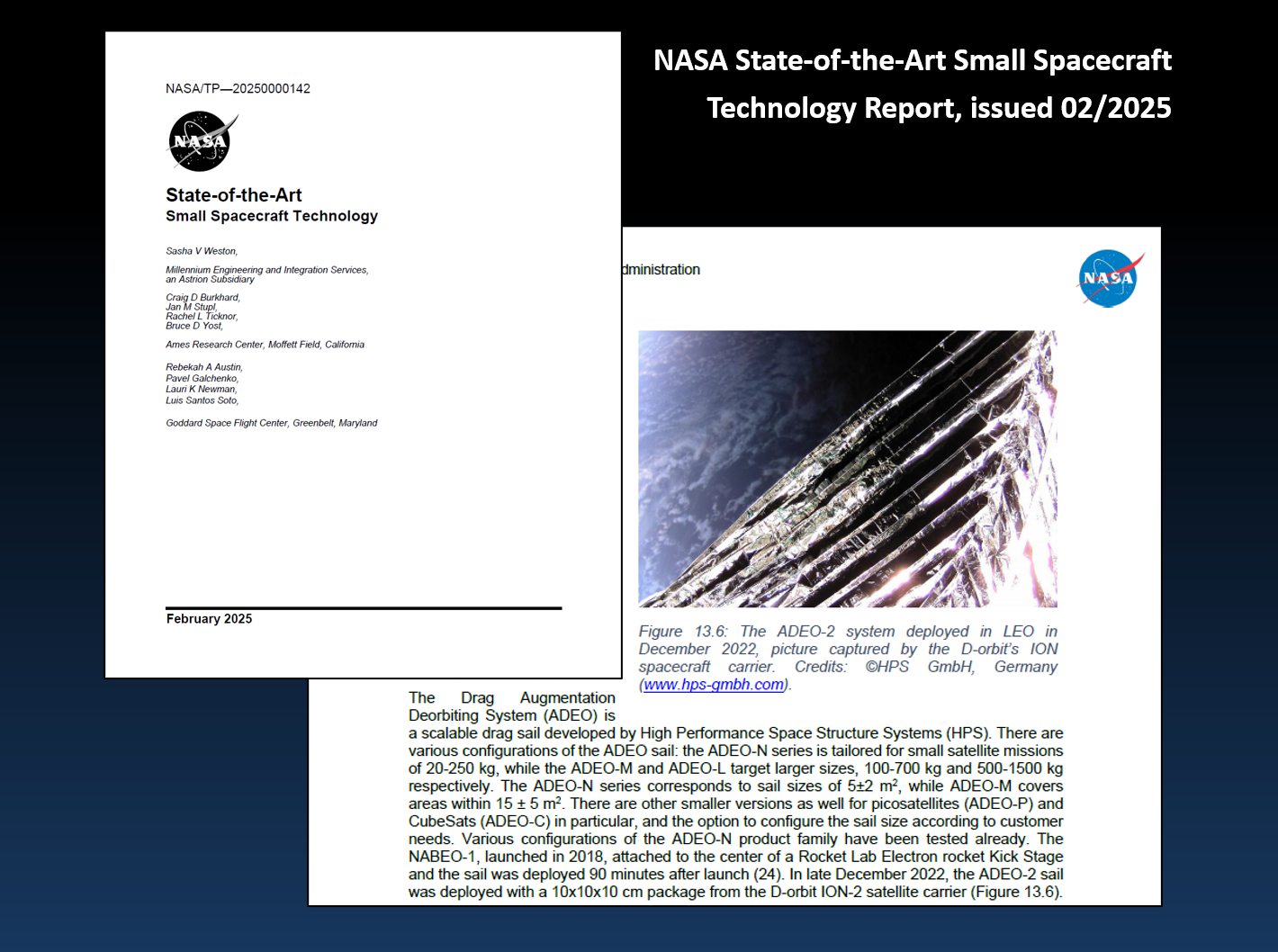

HPS with ADEO product family: top position in NASA’s technology report extended

A year ago, the deorbit module from HPS took its place at the top of the podium of the most important technology achievements according to NASA. This was because ADEO already had everything that the American space agency considered crucial for success at the time: top values up to TRL9, scalability and proven flight heritage. Exactly one year later: ADEO, now supplemented in the technology report by the presentation of the bestsellers ADEO-Cube and ADEO-Pico, maintains its position both against numerous Dragsail competitors and against other passive deorbit technologies.

HPS CEO Ernst K. Pfeiffer comments: “With ADEO, we are surfing at the top of the wave worldwide that we have created ourselves with this technology over many years of R&D – often with significant co-financing by ESA and DLR plus considerable company resources. And we are actually delighted with every attempt by other companies to establish deorbit sails on the market: The bigger they make the wave, the higher our product family sails on its crest.”

The movie to a world success

January 2025

ADEO – Space Heritage

ADEO (Atmospheric Deorbit Sail Module) is the name for an entire product family of drag sails for satellites from the German space company HPS, Munich. They accelerate the disposal of satellites from space to a period of less than five years and thus fulfill the prerequisite for the satellite to receive approval for launch into space in the first place.

The sail is scalable and available in many variants from series production. ADEO-N is tailored to small satellite missions of 20-250 kg, while the ADEO-M and ADEO-L series are designed for larger missions of 100-700 kg and 500-1500 kg respectively. The ADEO-N series corresponds to a sail size of 5±2 m2, while ADEO-M covers areas of 15 ± 5 m2 and ADEO-L 25 m2 and more. However, smaller versions have also been available for a year, especially for cubesats, e.g. an ADEO-P for 1U-6U satellites (1-20 kg) and an ADEO-C for larger cubesats (5-50 kg). A total of five versions are currently available to order, all of which reliably dispose of satellites from LEO – including those from higher MEO orbits when combined with satellite’s onboard propulsion – within the required time frame. A corresponding configurator for selecting the perfectly suitable ADEO module is available for individual mission calculation (ADEO Online Configurator).

Now there is a short film about the production and testing of the product family, as well as ADEO’s heritage story:

Based on over ten years of development, HPS has successfully completed a series of missions up to “full burn” and has thus firmly established itself at the top of deorbit technologies at qualification level TRL 9.

2018: ADEO-N1 (“NABEO”) was launched on a Rocket Lab Electron rocket kick stage back in 2018, with Peter Beck himself (CEO RocketLab) even personally handling the sail. On this flight, the sail was unfurled just 90 minutes after the launch. Visual ground observations confirmed the successfully deployed sail and its performance.

2021: In June 2021, ADEO-N2 (“Show me your Wings”) was launched into space by the spacecraft carrier ION-003 of the Italian launch service provider D-Orbit, as part of SpaceX’s Transporter-2 mission. The successful deployment of the sail in December 2022 was recorded by the ION carrier’s on-board camera. The integrity of the sail after one year in orbit was confirmed, again by means of the onboard camera. On December 8, 2024, HPS received confirmation that ADEO-N2 had completed its mission with deployment of the dragsail at 506 km orbit altitude in a record time of just two years after the 210 kg satellite’s “end-of-business” with fireworks of success at 120 km orbit altitude, beating international rules and regulations by three full years.

Even NASA ranks the ADEO module from HPS as the number one automatic passive deorbit technology in view of the qualification and Flight Heritage.

ADEO is now a bestseller not only with European institutions and companies, but also in the fully commercial markets of the USA and Canada.

Highest qualification levels, proven reliability and flight heritage combined with scalability, availability and attractive pricing make the ADEO product family a highly visible beacon in the global field of deorbit systems for all satellites that must comply with the new 5-year deorbit requirement to obtain launch authorization.

Click here for the latest clip about ADEO

————————-

Video: © HPS GmbH, Munich, Germany, www.hps-gmbh.com

Production: Daniela Creutz, www.bluecirceproductions.com

————————-

Fly, Falcon, fly!

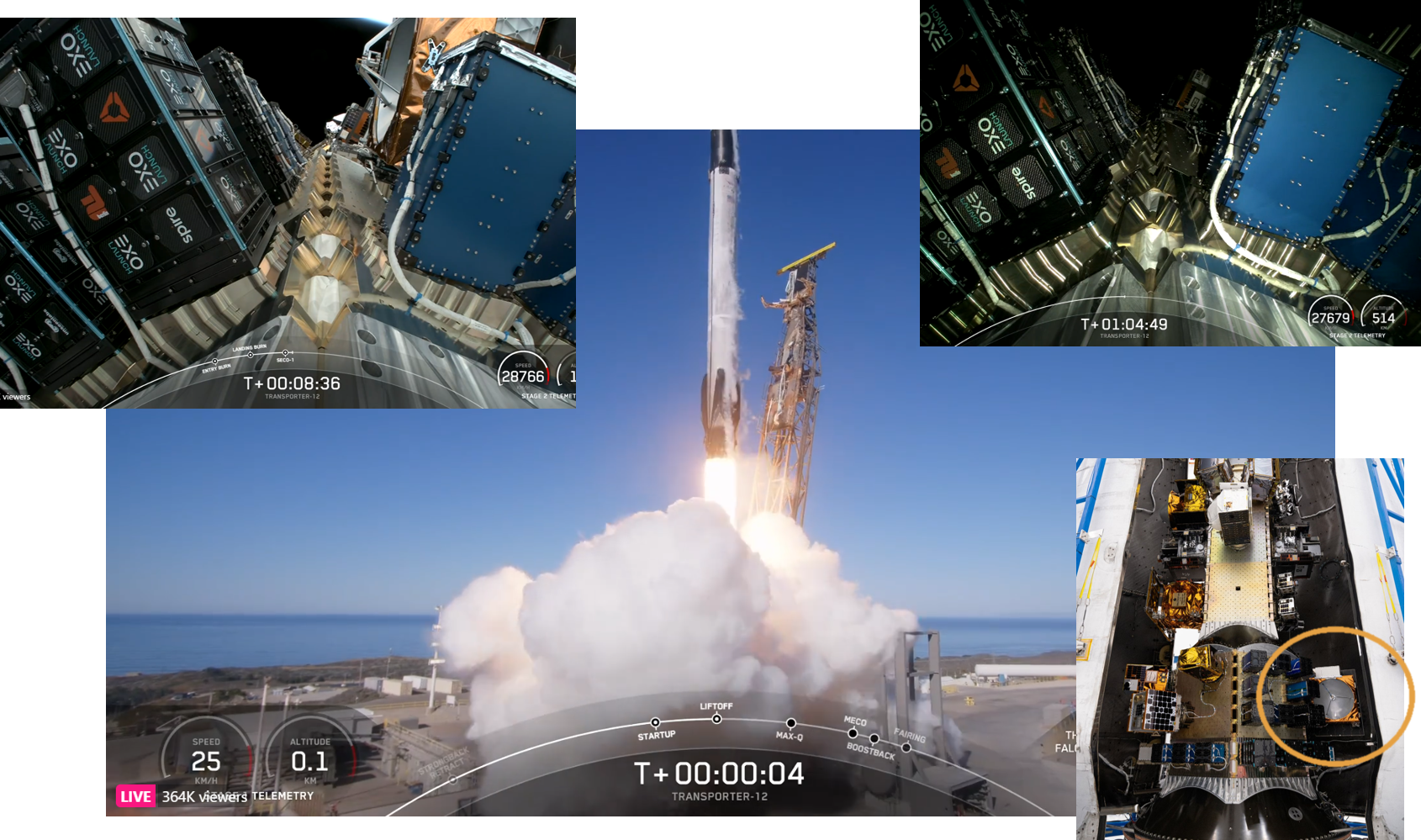

Two HPS contributions on board the Transporter 12 mission on January 14, 2025

Even HPS has never done this before: two of the company’s products are on their way to a sun-synchronous orbit on a Falcon 9 mission. This has been made possible by the rideshare- version of the SpaceX rocket named “Transporter 12”.

On the one hand, the contributions from HPS relate to the highly innovative BANT-1 reflector antenna for Reflex Aerospace’s premiere satellite – see also the HPS news item “HPS congratulates Reflex Aerospace” from today, January 14.

On the other hand, a contribution from HPS itself is the premiere. For the first time, HPS Germany and HPS Romania have jointly prepared a flight hardware with the MLI insulation of the central radiator in such a way that the thermo-optical properties of the satellite are maintained even under the most adverse conditions in space.

The satellite is Sky Bee-1 and part of a thermal infrared constellation HiVE that provides highly accurate yet cost-effective daily temperature data of the world’s land surfaces with a resolution of 30 meters for the benefit of agriculture, urban and industrial environments. The HPS teams of both European countries warmly congratulate their client OHB on the launch success. The first flight model SkyBee-1 is being developed under the InCubed Programme, co-funded by the European Space Agency.

HPS congratulates Reflex Aerospace on the successful launch of the “SIGI” satellite

Space premiere also for the innovative BANT-1 reflector antenna from HPS

On January 14, 2025, “SIGI”, the first satellite from the NextSpace company Reflex Aerospace, Berlin/Munich, was launched on board a Falcon 9 – Rideshare Mission Transporter-12. “NextSpace” is the term legally reserved for exclusive use by Reflex to describe the new speed in the development, production and provision of space technology, coupled with innovative versatility as a leitmotif for the performance of the product.

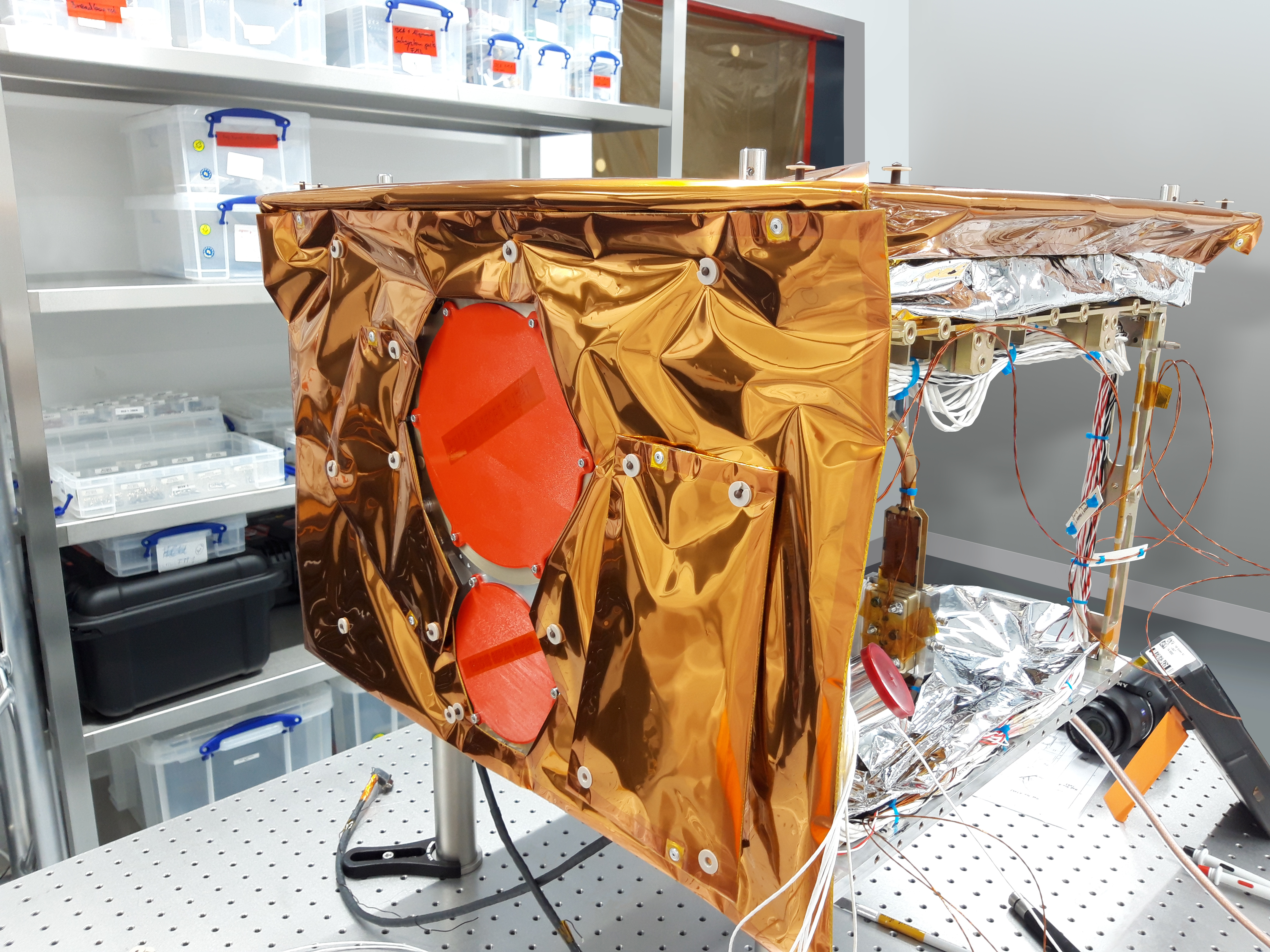

To a large extent, this also applied to an essential element of the satellite not manufactured by Reflex: the core broadband reflector antenna developed by HPS from the medium-sized space technology company HPS GmbH (Munich, Germany) with a cavity-backed spiral antenna as an axial feed for a wide bandwidth and considerable gain – and all that from order to delivery in just 12 months.

HPS congratulates Reflex Aerospace on the first launch of one of its products and looks forward to working with them on further NextSpace challenges in space.

Pictures by SpaceX

Antenna specialist HPS conquers new territory in RF applications

Antenna specialist HPS conquers new territory in RF applications with verification of innovative 3D production

Even formerly very sceptical augurs of space travel now agree that the ability to largely automate the series production of lightweight components while minimizing raw materials and ensuring maximum reliability will have a significant impact on the future development of applicable technologies.

However, the central prerequisite for the implementation of such visions is still a very classic step-by-step verification, in this case of two materials selected by the HPS engineers using the new ESA standard ECSS-Q-ST-70-80C.

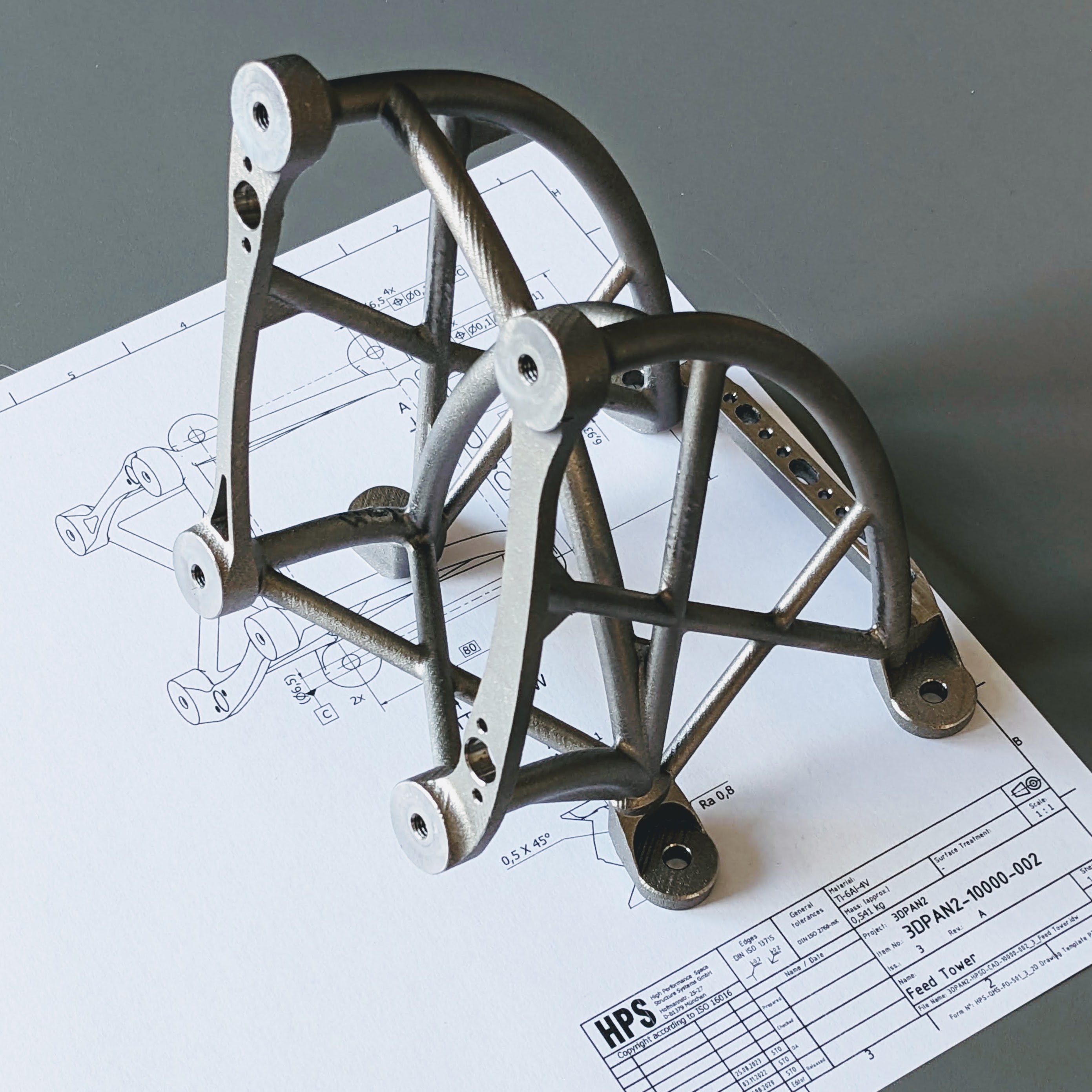

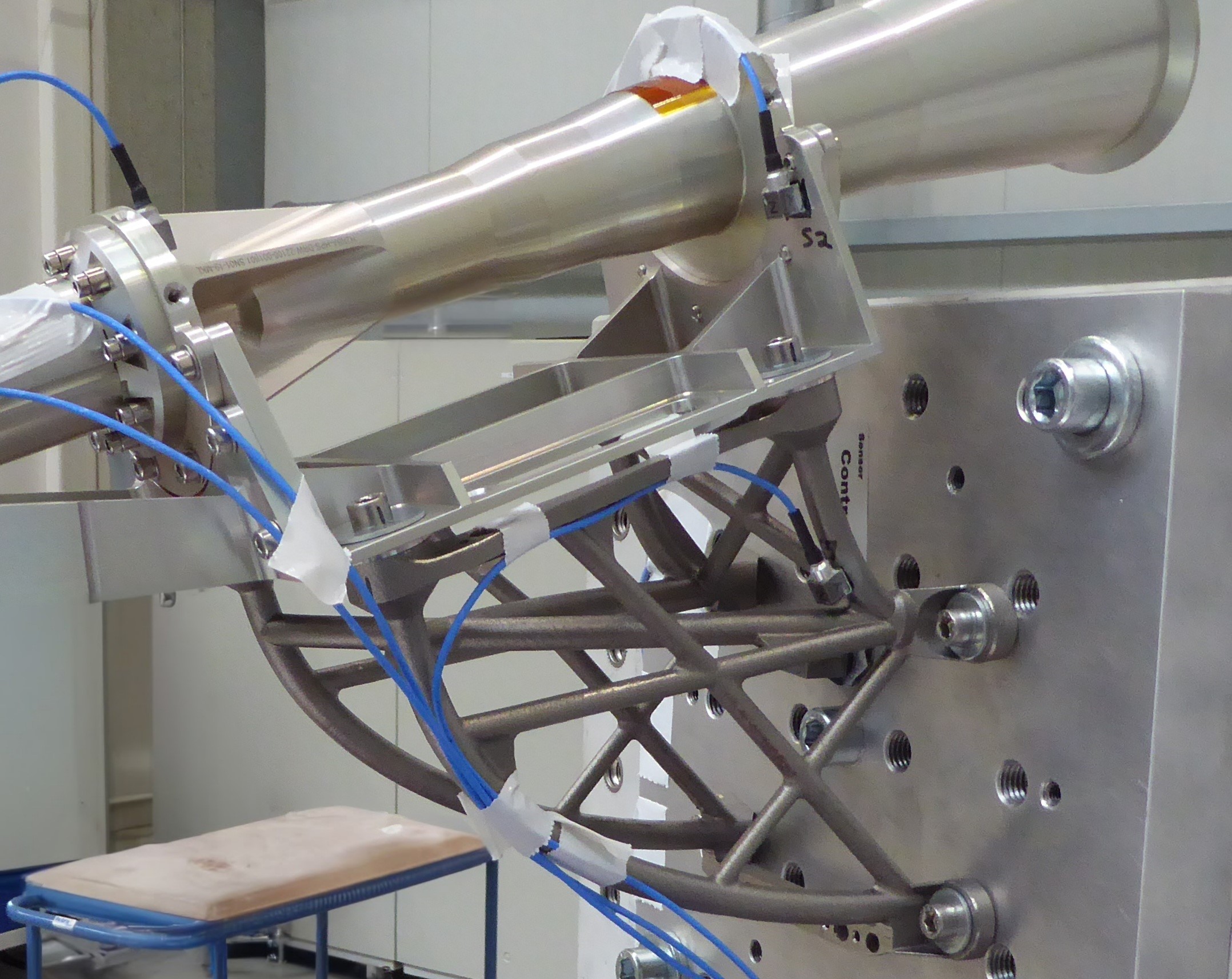

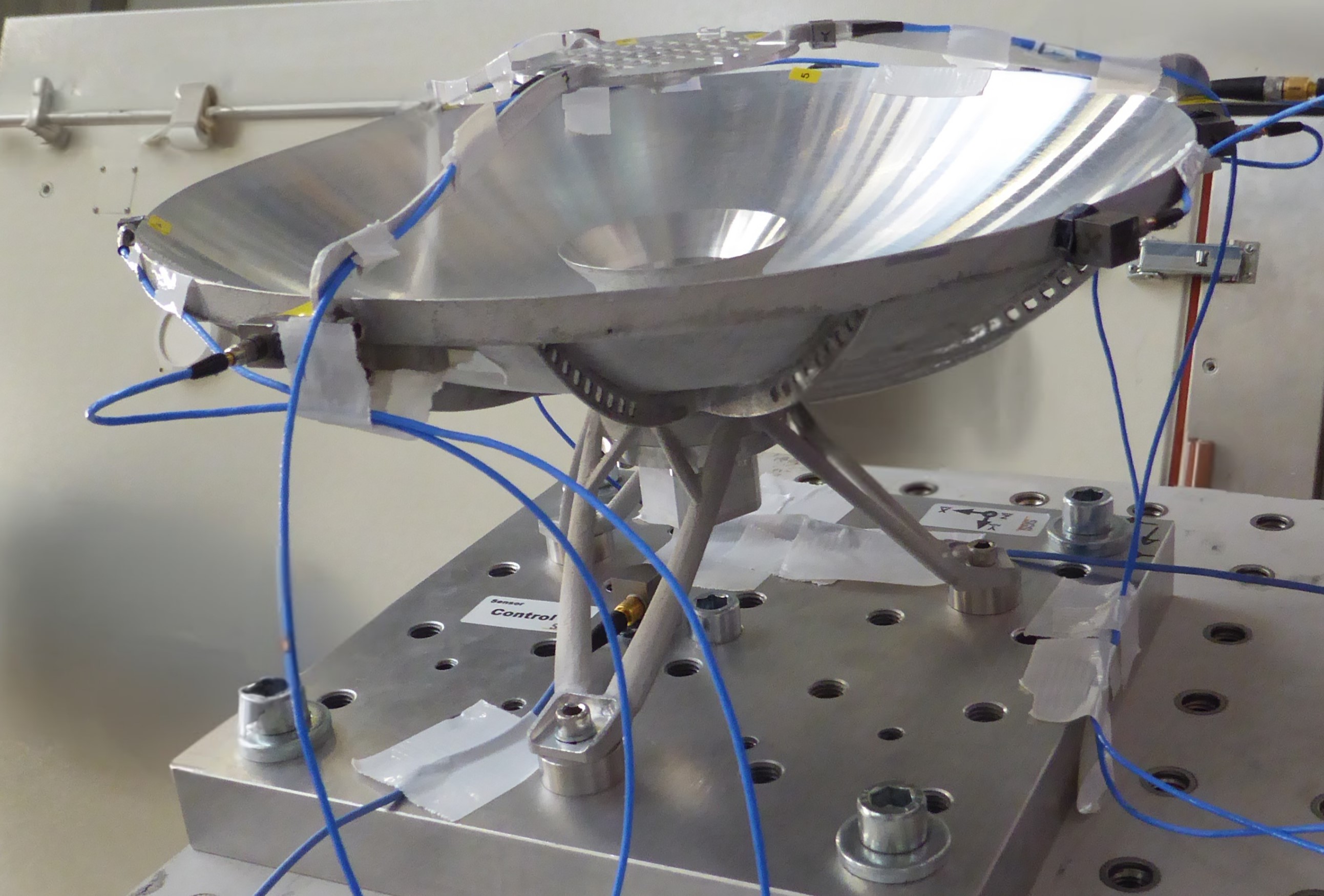

Given the future potential of such technology, the European and German space agencies have a primary interest in the success of the research at HPS and provided GSTP funding for the 3DPAN2 project: “3D-Printed Antenna 2” is a follow-up project to 3DPAN, which was completed five years ago and initially demonstrated the feasibility in principle of 3D-printed RF components.

The product objective was an extremely lightweight X-band antenna with a diameter of ~30cm for the data downlink of earth observation satellites. It was finally manufactured from the aluminum alloy SCALMALLOY at the sub-contractor APWORKS GmbH in Ottobrunn. In addition, a filigree feed support bracket made of titanium was manufactured for fold-out antennas by the long-standing HPS trusted partner, the Fraunhofer Institute for Material and Beam Technology IWS, Dresden, as a subcontractor.

Meanwhile, the respective designs and FE analyses, as well as their iterative optimization, were carried out by HPS in Munich itself.

The final tests delivered positive results that exceeded all expectations. This applied in particular to the RF performance of the X-band antenna in the Compensated Compact Range (Munich University of Applied Science MUAS). Resistance to vibration (sine + random) was also successfully demonstrated for both demonstrators at SGS GmbH, Geretsried: here too, everything went without complications, i.e. above all without damage or deformation. Even a final TVAC test (10 cycles between +120°C and – 120°C) showed no cracks or deformations on the demonstrators.

Olaf Stolz, the responsible project manager at HPS, summed up the project as follows: “The objectives of the verification processes were achieved without any restrictions: the additively manufactured demonstrators were 20% and 25% lighter than corresponding conventionally manufactured components – a well-known enormous advantage in space travel. There were no restrictions on qualification for space applications. We would like to thank our cooperation partners, especially Dr. Samira Gruber (Fraunhofer IWS) and Mr. Nicklas Schwab (APWORKS) for the extremely good and successful cooperation in the project, as well as ESA, in particular Ms. Isabel Olaya Leon, Technical Officer of the 3DPAN2 project.

HPS CEO Ernst K. Pfeiffer is delighted: “It is fantastic that we are already implementing 3D printed components with the technology results of the ESA GSTP program in current flight projects. A goal that we set 8 years ago and that is essential for the future market has now been achieved.”