A Quarter Century of Space Technology from Munich

December 2025

A Quarter Century of Space Technology from Munich

December 2025

The Munich-based space technology forge HPS GmbH celebrated its 25th company anniversary in 2025. Over a quarter of a century, HPS has, through its own efforts, developed from a small SME specialising in high-performance structures into a highly sought-after equipment and subsystem supplier across Europe, delivering demanding projects and missions for institutional clients (such as ESA and DLR), as well as commercial and defence customers, with the most innovative technologies.

Today, HPS is the leading address for precision-driven antennas, mechanics, thermal subsystem expertise, and lightweight structural technologies, for example as a valued subsystem-prime in flagship projects such as the LDRS development for the Copernicus-CIMR mission, supplier of critical signal intelligence antenna arrays, or development partner for serial MGSE solar arrays in the IRIS2 programme. At the same time, HPS is advancing active sustainability solutions for orbit with its own space debris solutions, such as the ADEO dragsail.

Furthermore, HPS is committed to driving forward Europe’s technological non-dependence and to developing products that previously had to be procured expensively from outside the continent. An outstanding example is the ultra-fine metal meshes of the highest precision at the micrometre level, known under the technical term Universal Space Mesh (USM), which, thanks to their combination of electrical conductivity and mechanical elasticity, are ideally suited for applications such as climate research, telecommunications, and Earth observation. On the looms of HPTex GmbH, the joint venture founded by HPS and Iprotex in Münchberg (Bavaria) in 2020, tailor-made MESH solutions are now being produced for the specific requirements of customers from all over the world—solutions found nowhere else.

Already four years earlier, HPS had established its Bucharest-based subsidiary High Performance Structures Inovatie si Dezvoltare S.R.L. (HPS-Romania) alongside its Munich headquarters, particularly for the development and production of mechanical and thermal space equipment, multi-layer insulation (MLI), secondary and tertiary structures, MGSE (Mechanical Ground Support Equipment), and antenna components, as well as engineering and integration services. This highly specialised team supports the growing Romanian space industry as well as key European missions (such as METOP-SG, BIOMASS, JUICE, SENTINEL 4, LISA) in the areas of design & engineering, production, and integration in their own clean rooms.

Altogether, HPS now employs a core workforce of 90 people in Munich, Bucharest, and Münchberg—with numbers rising, as additional specialists of all backgrounds are sought in Germany and Romania to tackle the various technological challenges posed by the rapidly expanding market that German, European, and global spaceflight presents to HPS.

“We look back with great gratitude on 25 years in which we have translated technological and mission requirements into functioning hardware with outstanding partners. Founded in 2000 by the two visionaries Reiner Klett (Kayser-Threde GmbH) and Professor Breitbach (INVENT GmbH), we have consistently followed the path of an organically growing SME independent of VC capital. Mainly supported by the many technology programmes of ESA and the national initiatives carried out within the German space programme, we are now firmly established in the market with our high-end products and are simultaneously scaling up for serial markets. In addition, we are consistently investing in sustainable solutions for the future of spaceflight, especially in LEO, so that we can contribute to avoiding space debris,” says Dr.-Ing. Ernst K. Pfeiffer, Managing Partner of HPS. “We have already achieved much, and we see even more ahead of us. We look forward to it.”

We wish you a Merry Christmas and a Happy New Year. And we would like to take this opportunity to thank you for placing your trust in us over the past 25 years at HPS, whether in the short or long term, as a customer, partner, subcontractor or employee.

Without you, we would not be where we are today with our high-tech products used in space.

THANK YOU!

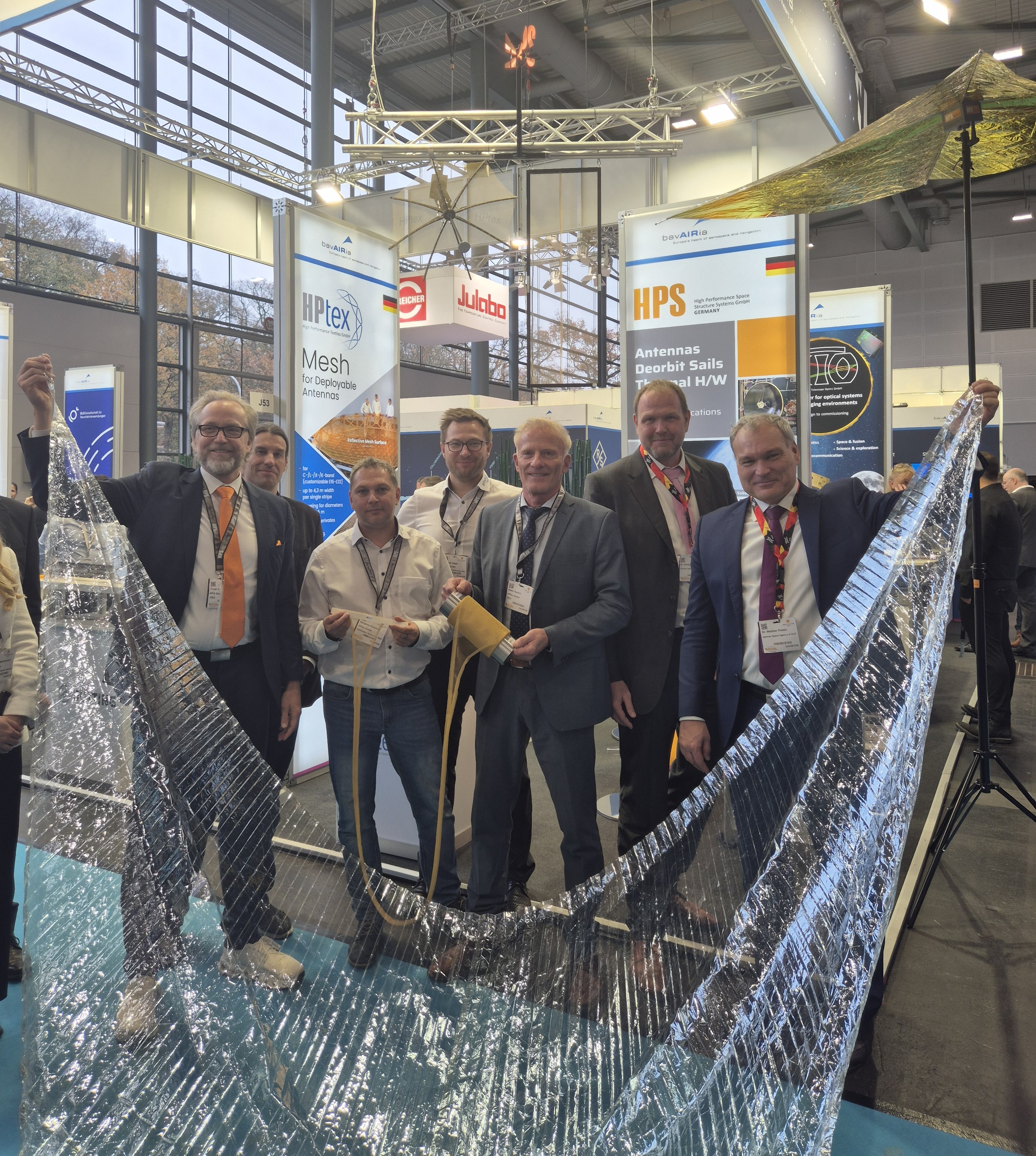

Innovative Raumfahrttechnologien live entfaltet und präsentiert.

November 2025

Am Mittwoch, dem 19. November 2025, empfing die HPS GmbH auf ihrem Messestand der Space Tech Expo 2025 in Bremen den DLR-Raumfahrtchef Dr. Walther Pelzer. Die CEOs und führende Vertreter von HPS München und deren Joint-Venture HPtex Münchberg informierten die hochrangigen Gäste der deutschen Raumfahrtagentur über die neuesten Fortschritte im Bereich der weltraumtechnischen Innovationen.

Im Rahmen des Besuchs wurden den Gästen zwei herausragende Entwicklungen live vorgestellt (siehe Bild):

Beide Technologien wurden zeitgleich und live am Stand als eindrucksvolle Demonstration entfaltet; sie stammen aus renommierten ESA-Technologieprogrammen wie GSTP und ARTES, welche den europäischen Raumfahrtunternehmen als Basis für stetige Wettbewerbsfähigkeit bieten.

HPS und HPtex waren Teil des von @BavAIRia großartig organisierten und schön arrangierten bayerischen Gemeinschaftsstandes.

Innovative Space Technology for Sustainable Satellite Disposal and Mitigation of Space Debris in the Spotlight

Unusual Event at SpaceTech Expo Bremen: HPS Hardware Handover at the OHB Stand

November 2025

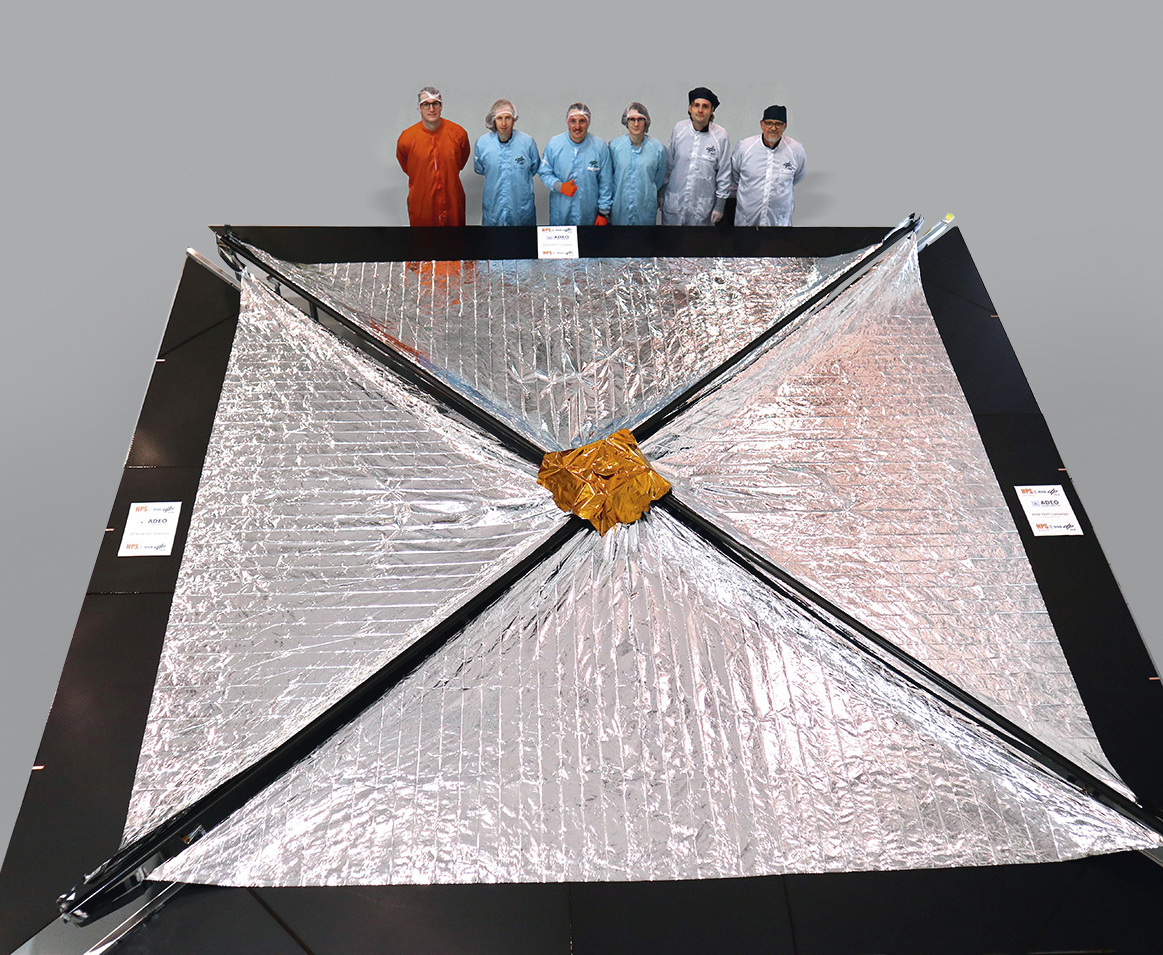

Unusual Event at SpaceTech Expo Bremen: HPS Hardware Handover at the OHB Stand

On 19.11.2025 at 15:30, an extraordinary event for a trade fair of this kind took place at the SpaceTech Expo stand of the German space company OHB in Bremen: For the first time, genuine ADEO hardware was ceremoniously and personally handed over between HPS (CEO Ernst K. Pfeiffer and CFO Peter Rauhut) and OHB (CEO Chiara Pedersoli and Member of Management Board Gianaldo Mantovani) for integration into a new satellite constellation – marking a strong, tangible sign of innovation and sustainability in the space sector.

HPS GmbH Supplies Drag Sails for Safe Satellite Deorbiting

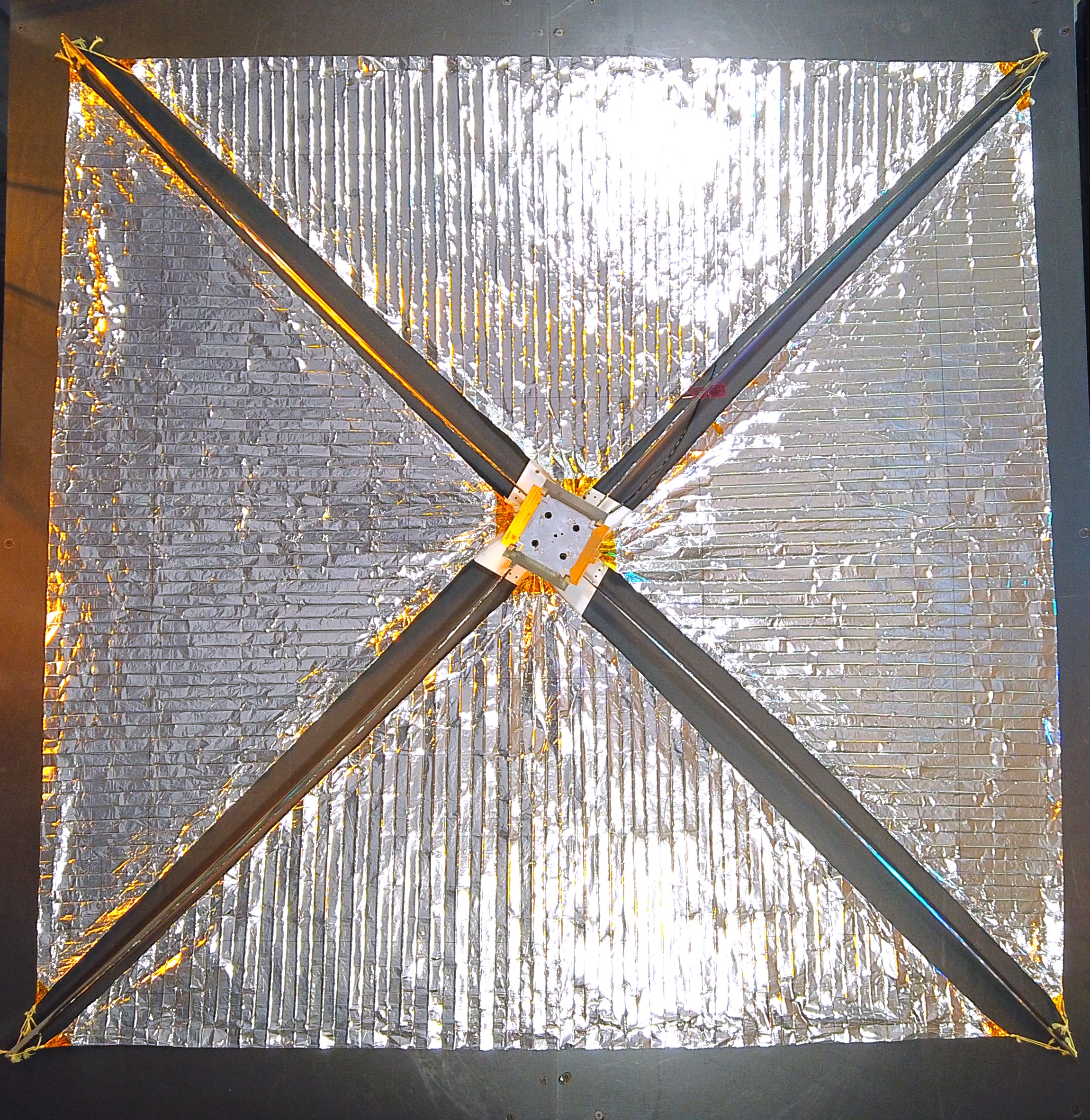

The Munich-based high-tech company HPS GmbH (headquartered in Munich, with a subsidiary in Bucharest) delivered four ordered ADEO-N(ano) class drag sails to its client, the renowned space company OHB, in Bremen. The ADEO modules are essential for the accelerated deorbiting of satellites at the end of their service life, ensuring compliance with the legal requirement of a maximum five-year deorbit period.

Technological Responsibility and Collaboration for Sustainable Space Activities

HPS is the developer and manufacturer of the ADEO product family of drag sails, designed for satellites of all sizes and weight classes in LEO and MEO orbits. Both companies – HPS and OHB – are also among the first signatories of the ESA Zero Debris Charter and are jointly as well as individually committed to its consistent implementation. By integrating ADEO into its LEO-PNT satellites, OHB underscores its top-level support for sustainable space activities, as well as for close collaboration between large system integrators and SMEs, which is of great and ever-increasing importance, especially in the context of European defence initiatives.

Significance of the Partnership and the Project

For HPS, collaboration with OHB is of particular relevance. For example, HPS supplied the downlink antenna for the OHB satellite of the HERA mission. The current delivery concerns a space programme of immense reach: the LEO-PNT satellite constellation is part of the ESA programme for the next generation of highly precise navigation and positioning technology in space. In general, ESA is committed with great dedication to consistently implementing its five-year deorbit requirements in its missions.

SpaceTech Expo Bremen as a Stage for Innovation and Sustainability

With its numerous space technology models and information stands from around one thousand exhibitors, the SpaceTech Expo in Bremen provided a unique backdrop for the handover of the ADEO modules, which are scheduled to launch into space in 2026. The timing of the fair and the already planned handover coincided by chance, so both companies spontaneously decided to celebrate this event as an extraordinary moment.

Dr. Ernst K. Pfeiffer, CEO of HPS GmbH, emphasised: “There is no better way to draw attention to pioneering technologies for the avoidance of space debris with a strong presence at by far the most important space fair in Europe – where all relevant institutions and companies of the industry are gathered. The ADEO modules of the N-version delivered here, are among the most in-demand ADEO-class of drag sails currently available.”

Continuity and commitment to small and medium-sized aerospace companies

November 2025

We are delighted that our managing partner and CEO, Dr. Ernst K. Pfeiffer, was elected spokesperson for the “AKRK – Working Group of German Aerospace SMEs” at the German Aerospace Center (DLR) for the sixth time in a row on November 12, 2025. Dr. Pfeiffer has held this position of responsibility without interruption since 2015 and enjoys a high level of trust and esteem within the industry.The AKRK represents the interests of around 40 leading German aerospace SMEs vis-à-vis key institutions and political decision-makers in Germany and Europe, including at events such as those organized by UNOOSA and the G20. With over 30 years of experience in the space industry, the focus is on a balanced space ecosystem in synergetic cooperation and the confident technological advancement of space travel. The aim is to actively shape the framework conditions for small and medium-sized companies in the industry and to drive forward future-oriented innovations.

Ernst K. Pfeiffer comments: “Being re-elected as spokesperson for German space SMEs is both a great honor and an incentive for me not to slacken my efforts. We are all working hard to create conditions that will strengthen the innovative power and competitiveness of our small and medium-sized enterprises in a resilient and sustainable manner for Germany beyond 2030. Important decisions are being made right now in the last two months of the year: in the run-up to the German 2026 budget decisions and the ESA Ministerial Council meeting, as well as in the Federal Ministry of Defense’s (BMVg) plans for the Bundeswehr’s space architecture. Germany can be proud of its large high-tech aerospace supply industry and its specialized small satellite expertise, and can now catapult itself into a global leadership position for the coming decades through appropriate industrial policy.”

Current Status of the Satellite Project in Kruibeke, Belgium

November 2025

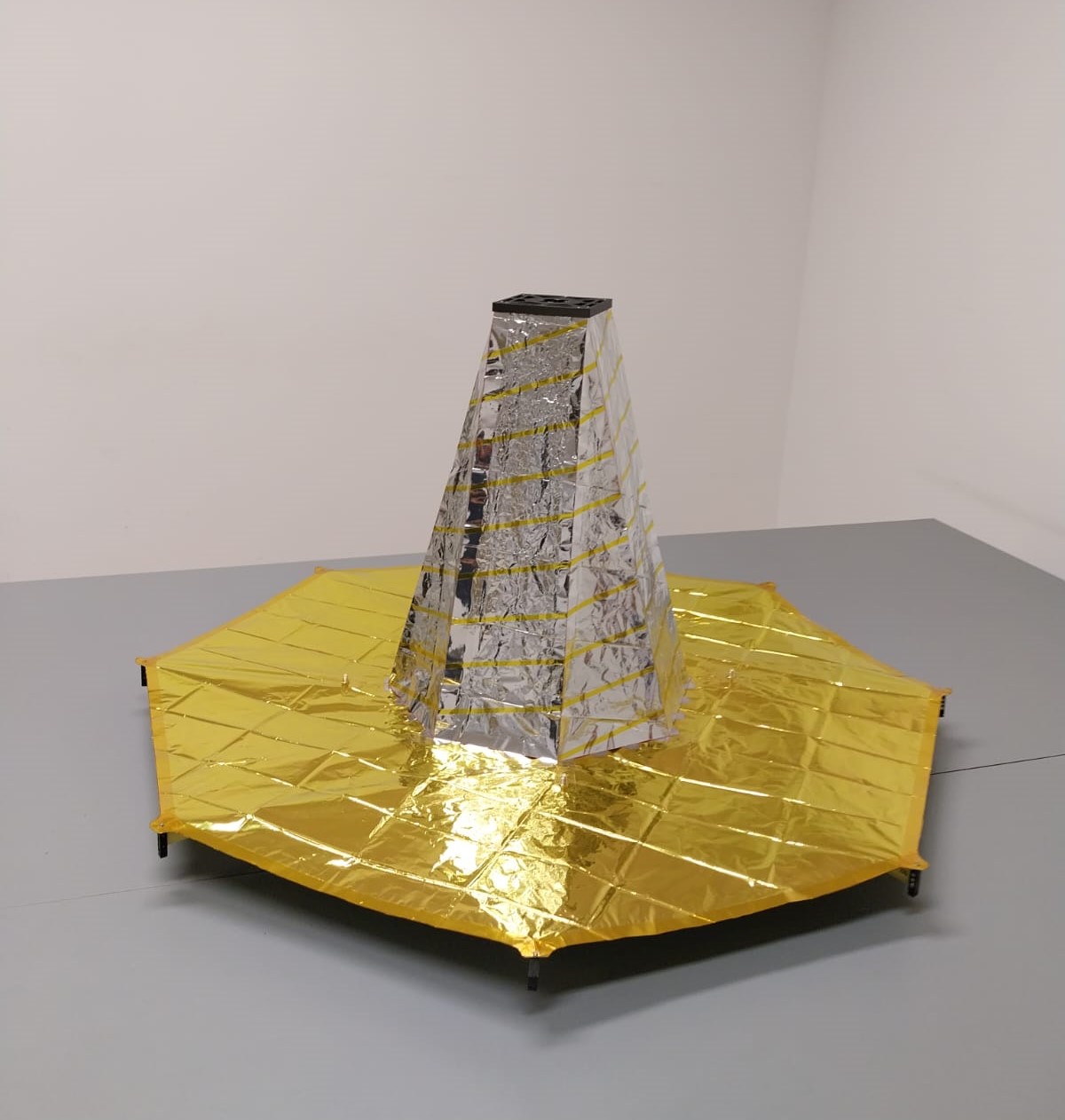

Back in July this year, it was announced that Redwire Belgium has also adopted HPS’s ADEO drag sail technology for satellite deorbiting. HPS is a global pioneer in developing sustainable space resource utilisation, and with its ADEO drag sail product family for all satellite classes in LEO orbits, it has established the international gold standard in deorbiting technology.

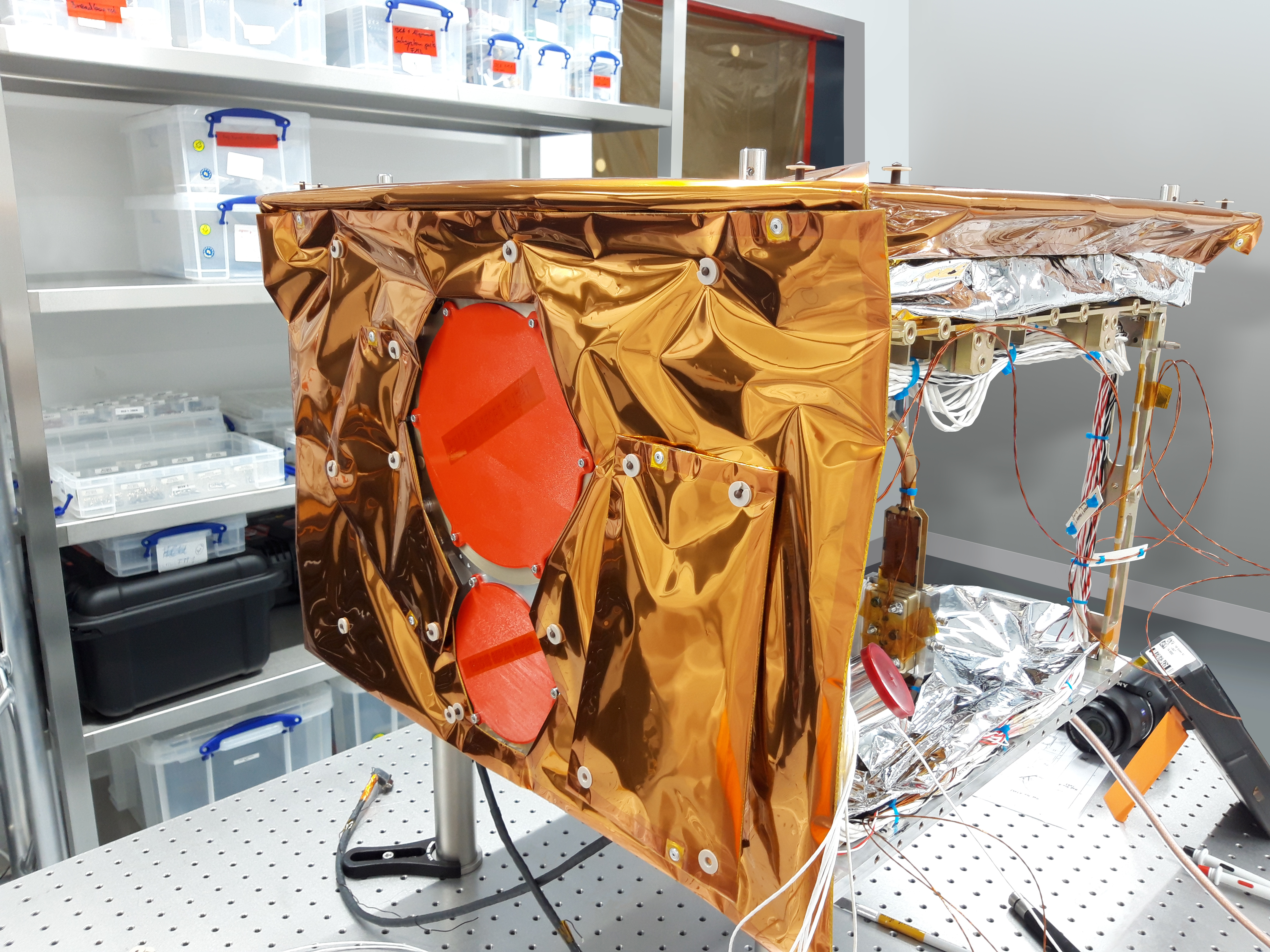

For Redwire’s current satellite project, HPS delivered the ADEO-L version – constructed under the ESA-GSTP-project umbrella of ADEO2 – of the drag sail in the summer. The Redwire spacecraft, developed specifically for an IOD/IOV mission in LEO for the European Commission, has medium-sized dimensions and therefore requires the ADEO-L deorbit module, featuring a surface area of 25 m².

The ADEO2 deorbit module was successfully integrated onto the satellite at the Redwire Satellite Processing Facility in Kruibeke, Belgium, on 3rd and 4th November 2025.

The next step will be comprehensive system tests of the fully integrated satellite—including environmental tests such as vibration, acoustic, and thermal vacuum (TVAC) testing—scheduled for the first quarter of 2026. The launch is planned to take place later in 2026 aboard a European launch vehicle, which is yet to be selected. Deployment of the drag sail for rapid and efficient deorbiting at the end of the mission is planned for about 1.5 years after launch.

As an integrated aerospace and defence company, Redwire focuses on autonomous systems and cross-domain operations utilising digital technology and AI automation. Redwire’s approximately 1,300 employees in the United States and Europe are developing innovative space and airborne platforms that are shaping the future of multidomain operations. The Belgian facility of Redwire can look back on more than 40 years of experience in spaceflight, during which it has developed spacecraft platforms and delivered innovative technologies for groundbreaking ESA programmes.

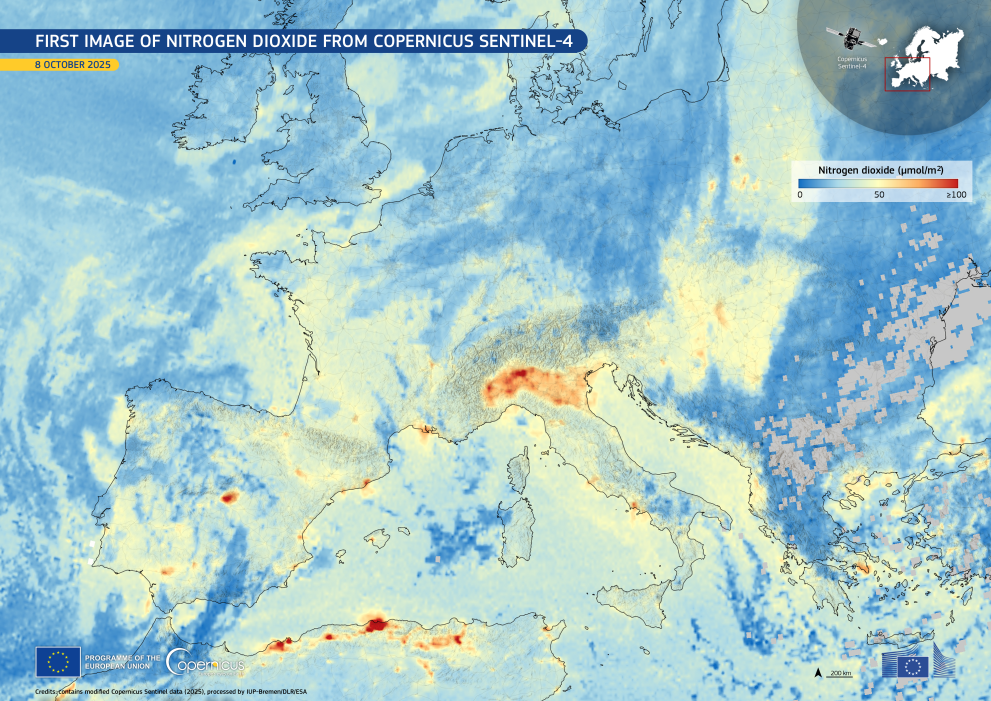

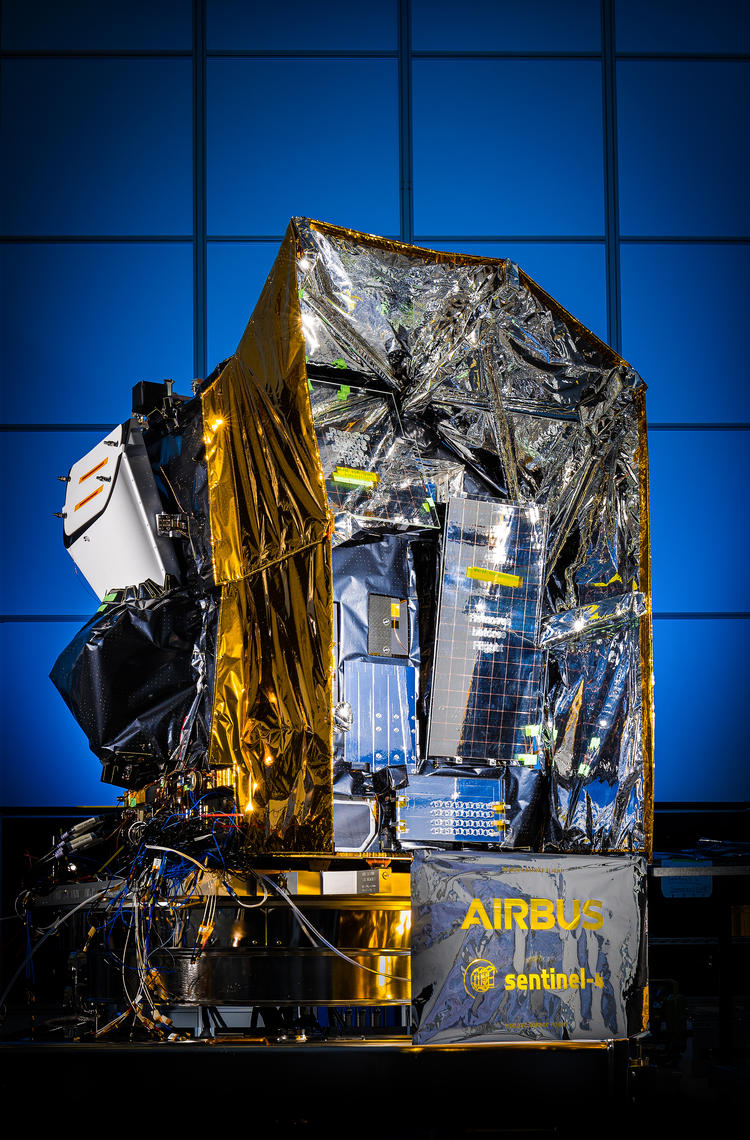

MTG-S1 and Sentinel-4 with Reliable Thermal Hardware from HPS

November 2025

With the successful operational launch of ESA’s MTG-S1 (Meteosat Third Generation – Sounder) mission, a new era in Earth observation has begun. On board is the highly sensitive Sentinel-4 instrument, which is now capturing air quality data in real time with previously unattainable precision – from around 36,000 kilometres up in geostationary orbit.

The journey there, the harsh environment itself, and the high-tech observation cameras all place extreme demands on every technical component: vacuum, intense solar radiation, dramatic temperature fluctuations between day and night sides. Only perfectly protected technology survives. This is where HPS comes in with its

High-Tech “Packaging” from a Single Source: Thermal Hardware Components by HPS

The Munich-based space technology company HPS was commissioned by OHB-Bremen, with Prime Airbus-Deutschland and end-customer ESA, for the design and production of all thermal hardware components on Sentinel-4 for this mission – a key role in its success. At the centre of this is the so-called Multilayer Insulation (MLI): a multi-layered insulation foil (see image, foil in gold/silver colour) that protects the most sensitive systems against overheating, overcooling or temperature gradients. This portfolio is complemented by radiators (see image, reflective plates), also supplied by HPS.

With this comprehensive thermal hardware package “from a single source”, HPS sets itself apart from the competition – and establishes new standards in reliability and system expertise.

Sentinel-4: Custom Protection for an Optical Precision Instrument

The optically complex Sentinel-4 instrument in particular demands special attention. To minimise stray light, a black MLI was developed – specifically for this application. In addition, a special “Sunshield MLI” protects the sensitive radiators of the instrument from direct sunlight – a central contribution to maintaining functionality in space.

As early as 2018, the MLI for Sentinel-4 was produced by HPS and integrated into the spacecraft system by the customer from 2021 to 2022, with on-site support from HPS. The MLI for MTG-S1 equipment was already manufactured in 2017 – an impressive example of long-term reliability and forward-looking planning within the European space programme.

International Success Story

The implementation took place in close cooperation between the locations of the HPS Group: the design was created in Munich, production was initially handled by the then subsidiary in Porto, today successfully complemented internally by the new HPS competence centre in Bucharest, which now plays a key role – especially in MLI and thermal straps.

This mission is exemplary of the HPS success model: an international team, high engineering expertise, continuous quality assurance, and absolute reliability – from concept phase to flexibility in final integration.

Future-Proof – Also for NewSpace

HPS is thus not only a proven partner in major ESA missions with clients such as OHB, Airbus, and ESA itself. NewSpace customers and operators of small satellites also find an experienced, flexible, and technologically leading partner in HPS – whether from Germany (HPS-DE) or directly from Romania (HPS-RO) for ISO8 satellite/equipment classes. With MLI from HPS, Europe’s space technology is on the safe side.

Picture by Airbus Defence & Space GmbH by Ralf Maurer

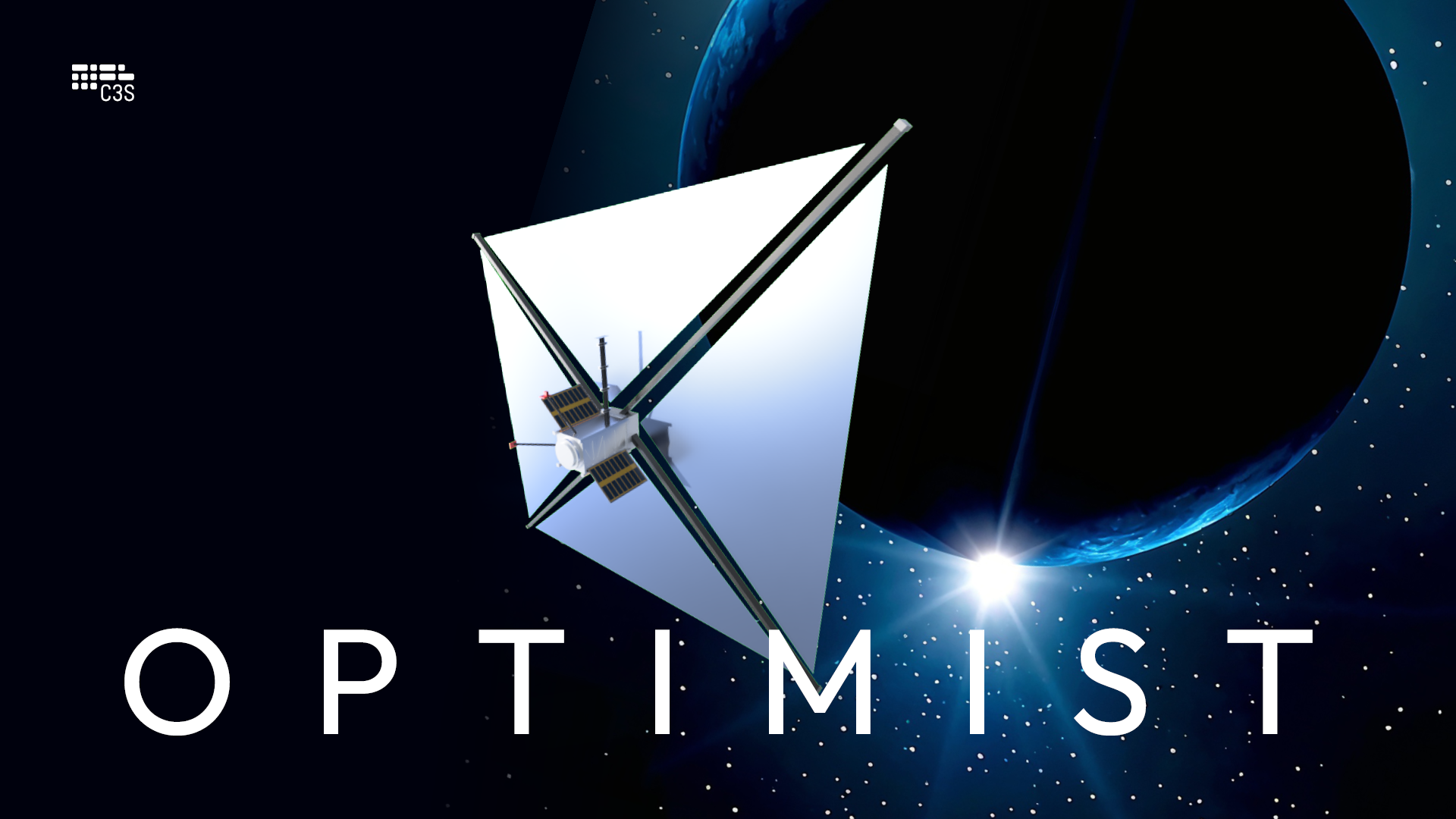

New in-orbit demonstration CubeSat project with Deployable Membranes based on ADEO-M

October 2025

The OPTIMIST mission, kicked-off in August 2025 to undergo a Phase A/B1, will involve a CubeSat deployed at an altitude of about 550 kilometers for one year. Its main goal will be to mature and validate the SAILOR payload technologies via statistically measuring near-Earth submillimeter, millimeter and centimeter sized debris populations and using a large deployable membrane (5–7 m²) equipped with acoustic sensors and a camera system. These instruments will detect and analyze impacts from small debris, providing valuable data for future, larger-scale missions: OPTIMIST will field-test essential technologies for the final target, the full-scale-mission SAILOR, which is dedicated to the scientific objective to investigate in-situ small space debris and its evolution. The results of the precursor mission OPTIMIST, to be launched in late 2027, will support the feasibility and design of a robust debris detection platform, which can be used with several satellites in the layer of a large satellite constellation for better debris impact predictions.

The first milestone of the project has already been completed with successfully closing the Mission Baseline Review with ESA. The Phase A/B1 study with breadboarding activities assesses technologies identified in SAILOR’s earlier phase, define mission architecture and evaluate launch options—favoring European launchers. Trade-off analyses ensure the mission is designed for maximum reliability and cost-efficiency, while meeting all technical requirements.

Under the project-lead of C3S (Hungary), HPS-Germany is responsible for the deployable membrane module, which is based for the OPTIMIST Mission on HPS’s deorbit module ADEO-M. HPS-Romania will perform the membrane manufacturing and the acoustic sensor bonding process. Further project partner under the prime C3S is University of Kent (UK) ensures extensive knowledge at the space debris science part and access to facilities to perform experimental simulation of hypervelocity impacts.

With SAILOR’s closure of Phase A and start of Phase B1 and the incorporated by the OPTIMIST precursor study, the SAILOR-project is poised to make significant progress toward safer and more effective management of space debris, paving the way for future missions that will help protect Earth’s orbital environment. SAILOR and OPTIMIST are part of ESA’s Space Safety Programme (S2P), which is dedicated to protect Earth’s and in-orbit infrastructure from dangers from and in space.

CIMR-LDRS 8m-EQM Assembly-Story, Episode 2/12

October 2025

Recapping the first episode of our 12-part series, the CIMR mission is multi-hundred million euro ESA mission to measure sea-ice concentration, sea-surface temperature, sea-surface salinity, and more.

Our focus in the groundbreaking mission, is the Large Deployable Reflector Subsystem (LDRS) – a combination of complex state-of-the-art technologies, built by the best minds across Europe.

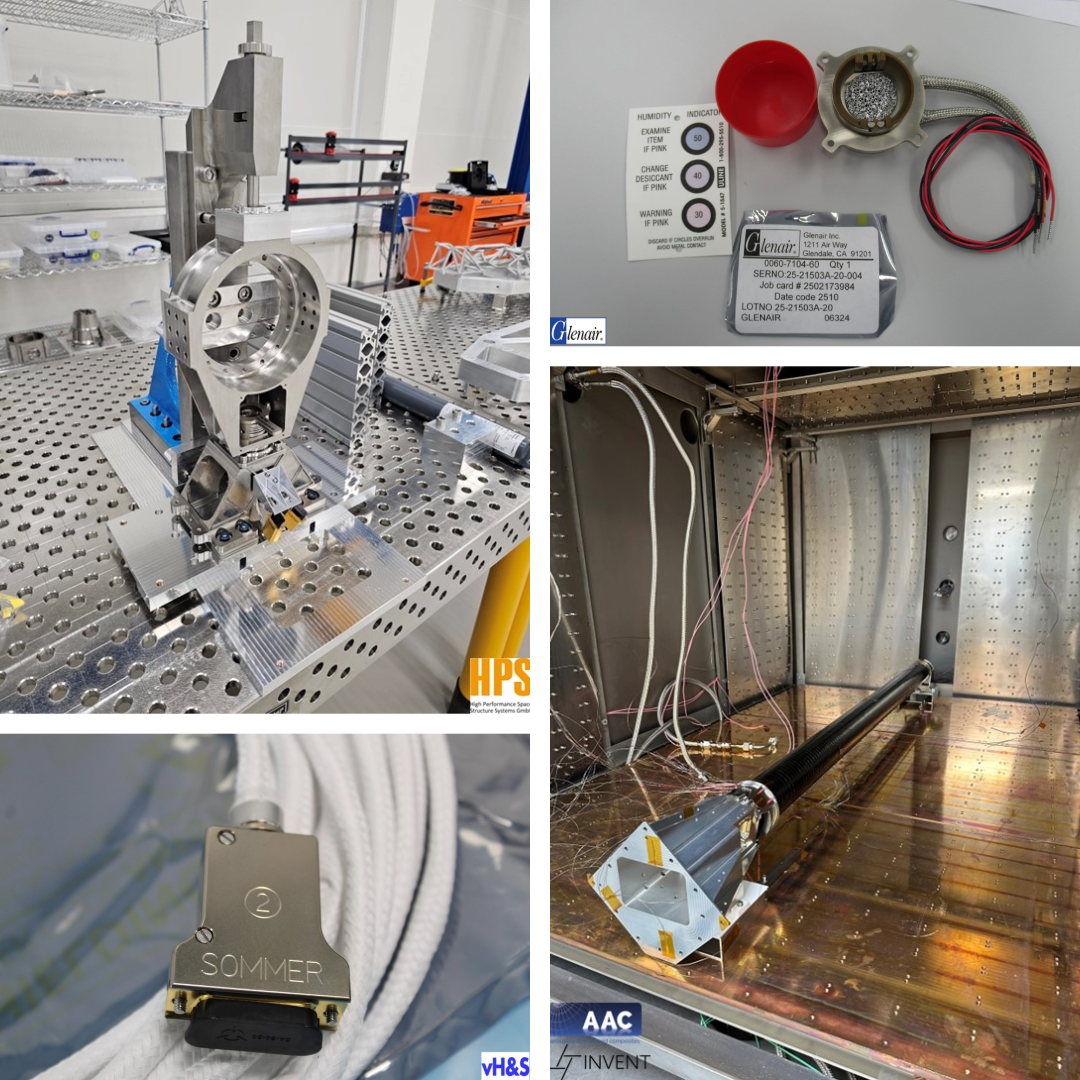

In today’s episode we will zero in on the day-to-day progress. Starting with the image on the upper right, release nuts from Glenair (which are used in HDRMs (Hold Down Release Mechanisms) to either keep space equipment stowed or to deploy it, have been procured and integrated into the HPS-Deployable Arm Isostatic HDRM (see upper left image). This isostatic HDRM will at some point be assembled onto the full DAA (Deployed Arm Assembly) of which one Arm Segment (see lower right image) has been through Thermal Vacuum Cycling at AAC in Wiener Neustadt (AT).

The lower left picture shows the arrival of the DRA harness built by VH&S (DE) at LSS premises (DE). This harness will connect the same Arm segment to the LSS-DRA (Deployed Reflector Assembly).

Stay tuned for more insider info as we observe and learn together how an ESA mission is realized.

HPS/LSS, 10.10.2025

HPS Romania and OHB Germany Sign Major Subcontract on Delivery of Radiators for ESA´s Space Mission LISA

October 2025

Just a few months after the groundbreaking contract between the European Space Agency (ESA) and OHB for the LISA mission, another milestone has been reached: HPS Romania (HPS-RO) has signed a multimillion-euro contract with OHB Germany to deliver a critical component for one of ESA’s most ambitious science missions to date.

LISA (Laser Interferometer Space Antenna) stands as one of the ESA’s science cornerstone missions, aiming to explore the deep-space phenomena of gravitational waves. These tiny ripples in the fabric of space-time hold answers to some of the most fundamental questions about our universe, since LISA will be the first space-based observatory to detect and measure gravitational waves, offering insights into phenomena like black hole mergers and galactic formation. The mission requires three spacecraft flying in a triangular formation across 2.5 million kilometers, using laser interferometry to detect distortions in space-time with unprecedented precision.

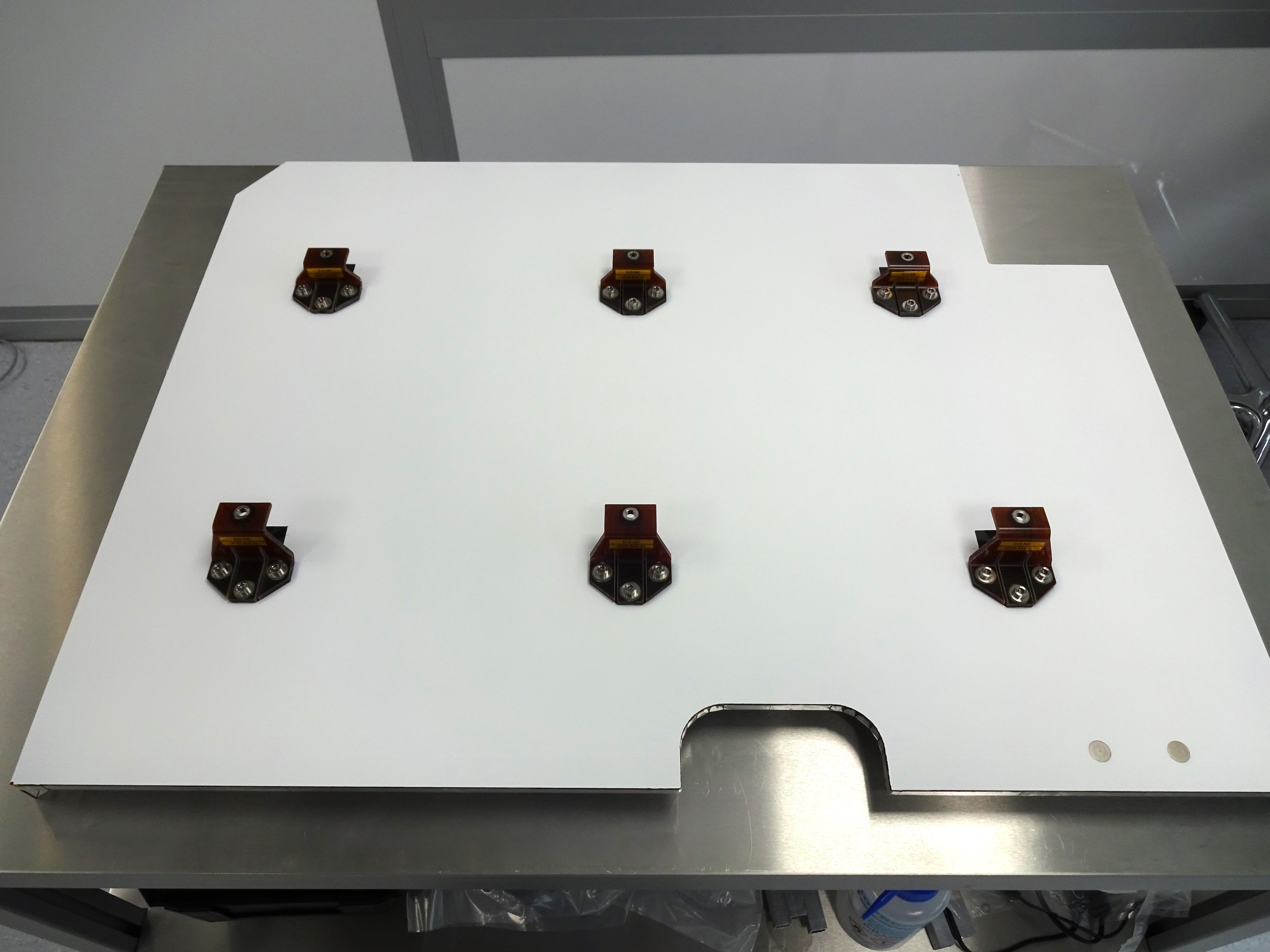

As part of this mission, HPS Romania will supply essential thermal radiators that ensure the spacecraft’s high-performance instruments and electronics remain within optimal temperature ranges by emitting the satellite’s heat via large metal structural panels into open space. Without these radiators, the delicate measurements LISA must take across millions of kilometers in space would be compromised.

This comprehensive contract covers Phases B2 and C/D, spanning a total of several years. It includes the production of advanced, ultra-lightweight radiator systems—one of the most visible and significant hardware contributions ever made by an ESA New Member State industry to a flagship space mission.

“We are deeply proud that Romania, through HPS-RO, is stepping into a frontline role on a global mission of this scale,” said Astrid Draguleanu, COO of HPS Romania. “This contract is proof of what consistent support, national policy, and strategic industrial partnerships can achieve.”

The contract also reflects a remarkable success for ESA and national industrial policies, showcasing how New Member States like Romania (official ESA-member since 22.12.2011) can rise to deliver high-performance, flight-critical products for leading space missions. In just nine years since its founding, HPS Romania — founded in 2016 and backed by technology programs, ESA special initiatives, national investments, own investments and the support and investments of its parent company HPS Germany — has evolved into a key contributor to European space infrastructure.

Over the next two years, HPS Romania will develop mission-specific manufacturing processes to realize an extremely lightweight radiator design tailored for space. This phase will be followed by four years of serial production, supplying radiators for all three LISA satellites: The radiator systems are built using a “built-to-print” approach, delivering around 50 high-performance sandwich panels during Phase C/D. Each panel can measure up to 1.5 by 2.0 meters and contains hundreds of inserts, followed by specialized thermal painting.

This contract is part of HPS-RO’s core product line “Thermal Hardware”, which includes:

In addition, HPS-RO’s broader portfolio supports ESA and commercial missions with:

For actual and potentially new customers, the LISA radiator contract is a strong statement of HPS Romania’s capabilities as cost-efficient supplier for high-end space equipment. For ESA and OHB, it confirms the strategic value of continued cooperation with a highly reliable and innovative partner. And for Romanian institutions and decision-makers, it’s a symbol of the nation’s growing role in cutting-edge space exploration.

CIMR-LDRS 8m-EQM Assembly-Story, Episode 1/12

September 2025

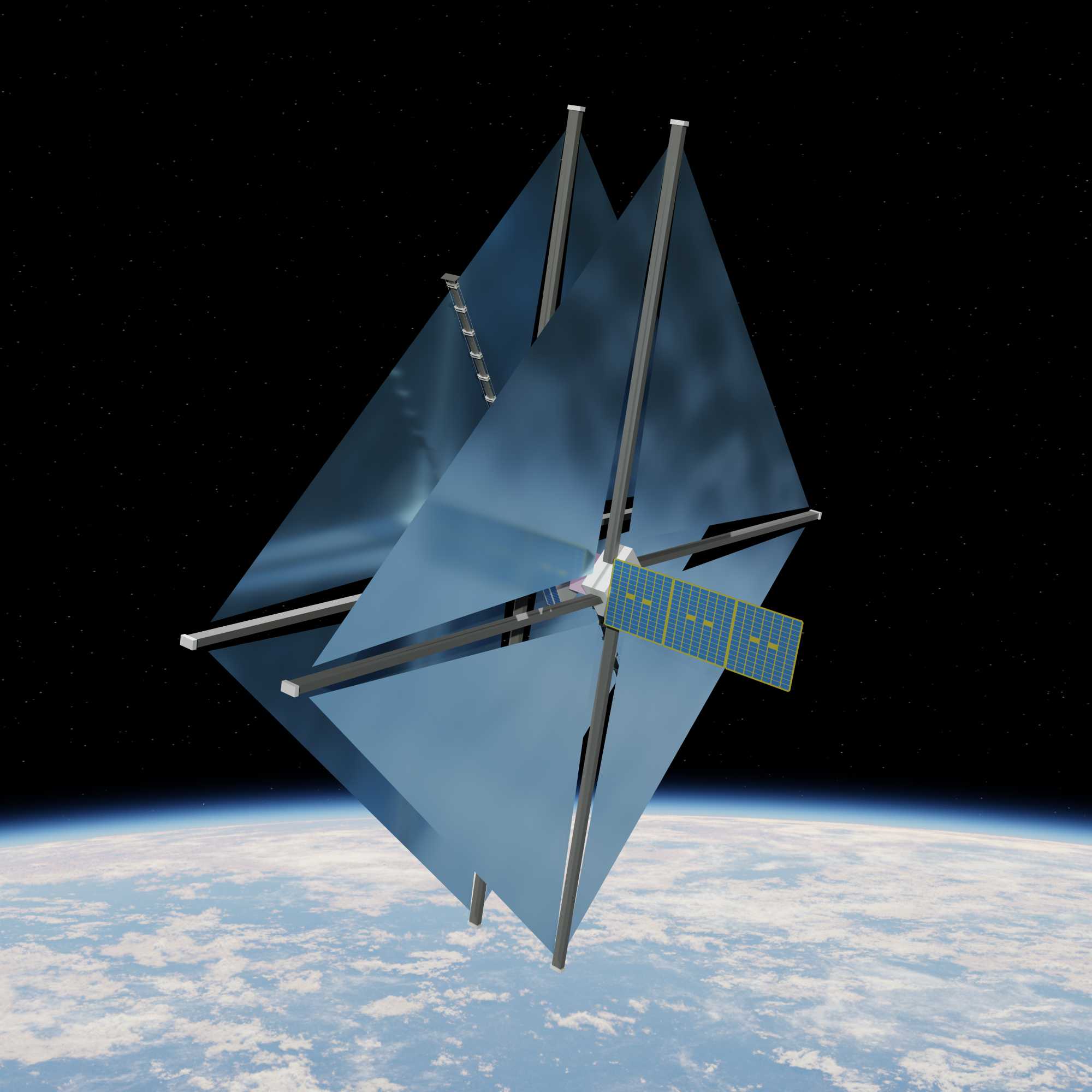

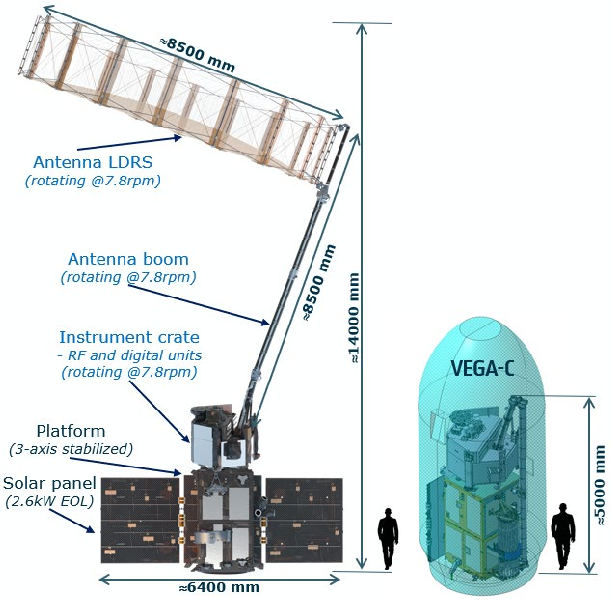

The goal is as ambitious as the means: technological non-dependence for Europe in space with a deployable reflector construction for high frequencies (Ka band) measuring eight meters in diameter on an equally deployable eight-meter-long arm, which rotates around its own axis eight times per minute in orbit. Extreme requirements: for example, an RMS (root mean square) value for surface accuracy that is to be considerably less than a few thenths mm over the entire 50 m2 reflector area, or a maximum permissible deviation of only 10 mm from the nominal value at the tip of the arm 8 m away, including vibrations, centrifugal force, and thermal distortions. Overall, the Large Deployable Reflector Subsystem (LDRS) consists of reflector, arm, deployment control electronics, harness, various hold-down and release mechanisms, and thermal hardware. This is the €120 million task of the LEA consortium (product name: Large European Antenna) of more than a dozen space companies, mainly SME, from eight countries led by HPS/LSS.

Now that the most difficult part, the coordination of the design and structural analysis between the large LDRS and the satellite, as well as achieving the “manufacturing readiness” of all components through countless process developments, has now been overcome, the “Engineering Qualification Models (EQM)” is now in the middle of production. We want to take you with us in a sequel story in 12 episodes.

As a reminder in relation to our LEA-team: Munich-based LSS GmbH is responsible for the Deployable Reflector Assembly (DRA). The unique Ka-band gold-plated MESH for the DRA is developed by HPtex GmbH, located in the German textile-triangle in Upper Franconia (DE). The unique Ka-band MESH for the reflector is produced by HPtex GmbH located in the textile-triangle Upper Franconia, the 9m x 9m gold-plated EQM-Mesh (see picture) has already been produced. INVENT GmbH, Brunswick (DE), is supplying the carbon fiber reinforced tubes (see picture) for the 8-meter “Deployable Arm Assembly (DAA)”, the first EQM-segment is already under inspection. NanoSPACE AG, Switzerland is developing and producing the highly accurate and stable motor-driven hinges for the arm. INEGI Portugal has already delivered the 0-g ground test support equipment for the DRA to LSS, the final tests for the 0-g DAA-GSE are in full swing before delivery (see picture). HPS S.R.L., Romania is currently finalizing under great time pressure one assembly and transport ground support equipment (MGSE) after the other (see picture). HPS GmbH, Munich, as direct contractor of the satellite Primes ThalesAleniaSpace, Rome (IT), has the LDRS subsystem responsibility, as well as that for the deployment arm DAA.

When CIMR embarks on its mission aboard a Vega C in 2029 to observe ice sheets and snow from dawn to dusk in a sun-synchronous orbit, this will be a step forward in terms of critical technologies, as LDRS are also products for a range of military applications that can contribute to increased independent defense capabilities, important especially in these days.

Sequel follows.

HPS/LSS, 16.09.2025

HPS brings space technology to the world’s most iconic rock festival

August 2025

Wacken 2025 – Countdown is On

HPS team heading to the Space Camp

On July 23rd, the HPS team departed for Wacken Open Air 2025. The next day, we began setting up at the Space Camp to be ready for the pre-opening on July 27. With our HERA antenna and the ADEO mockup, we brought cutting-edge space technology to one of the world’s most iconic music festivals.

We looked forward to an exciting week ahead – filled with inspiring conversations, valuable encounters, and the opportunity to meet other exhibitors in person.

Wacken 2025 – let the mission begin.

Wacken 2025 – Space has Landed

A powerful start for HPS at the Space Camp:

After the first full days at Wacken Open Air 2025, it became clear: our mission had launched with great success. At the Space Camp, hundreds of visitors stopped by our booth to explore space technologies up close. The interest was remarkable – from insightful questions and inspiring discussions to several spontaneous applications for jobs in space, even from career changers out of the automotive industry.

Highlights from the first days:

Even with challenging weather conditions, our team remained motivated and fully committed. We looked forward to the coming days at Wacken Open Air until August 3, continuing to combine the fascination of space with the energy of the metal festival.

Wacken 2025 – What a Ride it Was!

HPS rocks the Space Camp at the world’s most famous metal festival

After an unforgettable week at the world-famous Wacken Open Air Festival, it is time to look back on an incredible Space Camp mission. What began as a collaboration between music, science fiction, and real space technology turned into one of the highlights of the festival – for us as exhibitors and for thousands of fascinated visitors alike.

Our highlights from Wacken 2025:

Mud, Metal, and Motivation:

Despite Wacken’s legendary weather and muddy grounds, our team embraced the spirit with boots, energy, and enthusiasm. The atmosphere was not only fun for us – the passion and excitement clearly resonated with the guests, leaving many inspired by the unique connection between heavy metal culture and space innovation.

Thank You for the Ride, Space has arrived

This unforgettable week would not have been possible without the outstanding organization by our partners: A heartfelt thank you to BDLI and Fraunhofer AVIATION & SPACE for bringing the Space Camp vision to life and for providing such a professional framework.

We also thank all exhibiting colleagues of the space ecosystem and visitors who contributed to making Wacken 2025 a one-of-a-kind experience. Wacken 2025 will stay in our memories for a long time – and we are already looking forward to what comes next.

![IMG-20250801-WA0058[1]](https://www.hps-gmbh.com/wp-content/uploads/2025/08/IMG-20250801-WA00581.jpg)

![IMG-20250729-WA0034[1]](https://www.hps-gmbh.com/wp-content/uploads/2025/08/IMG-20250729-WA00341.jpg)

![IMG-20250728-WA0128[1]](https://www.hps-gmbh.com/wp-content/uploads/2025/08/IMG-20250728-WA01281.jpg)

![IMG-20250730-WA0066[1]](https://www.hps-gmbh.com/wp-content/uploads/2025/08/IMG-20250730-WA00661.jpg)

Redwire Belgium also relies on the gold standard of deorbit technology: the ADEO dragsail from HPS

July 2025

Twelve years ago, it was just an idea: quickly and inexpensively removing spent satellites from space traffic – quite simply with an automatic brake sail. Today, HPS, the global pioneer of development to ensure the sustainable use of space as a resource, is the international gold standard in deorbit technology with its ADEO dragsail product family for all classes of satellites on LEO orbits. From experimental university projects to global constellations: satellite manufacturers and operators from the EU and Asia, Australia and America rely on ADEO to reliably dispose of their spacecraft within the prescribed window of a maximum of five years after the end of operation.

The latest example: US-corporation Redwire´s branch in Belgium. The integrated aerospace and defense company focusses on autonomous systems and multi-domain operations leveraging digital engineering and AI automation. Redwire’s approximately 1,300 employees located throughout the United States and Europe are committed to delivering innovative space and airborne platforms transforming the future of multi-domain operations.

Redwire’s facility in Belgium has more than 40 years of spaceflight heritage developing spacecraft platforms and success delivering innovative technology for game-changing ESA programs.

The spacecraft specifically designed for this mission will operate on LEO. Its weight as a midsize satellite requires a deorbit module of the ADEO-2 class series, which is now with integrator Redwire. HPS CEO Ernst K. Pfeiffer: “We at HPS in Munich and Bucharest are delighted to be able to count this prestigious customer Redwire among our ADEO customers. The importance of Redwire´s role model function for others as a responsible space company cannot be overestimated.”

Experience space in person at Wacken Open Air 2025

July 2025

At the end of July, Wacken will be reaching for the stars: Wacken Open Air will be bringing numerous players from the German space and astronomy sectors to the field – including astronauts.

As part of a special collaboration, visitors can look forward to a space camp with an exciting and informative program on the topic of space. Partners include ArianeGroup, the Astronomical Society (represented by the Max Planck Institute for Radio Astronomy, Bonn; the House of Astronomy, Heidelberg; the Institute of Physics and Astronomy at the University of Potsdam), the German Aerospace Industries Association (BDLI), CRAF, the German Aerospace Society (DGLR), Fraunhofer AVIATION & SPACE, HPS, Hylmpulse, NEUROSPACE, OHB, and POLARIS Spaceplanes. A special highlight is the visit of astronaut Alexander Gerst and astronaut Rabea Rogge to Wacken Open Air.

Rockets, rovers, stars, and satellites: In addition to large-scale exhibits such as a replica of the European Ariane 6 launcher, a suborbital rocket from HyImpulse, a moon balloon from OHB, and a prototype of the MIRA 1 space plane from POLARIS Spaceplanes, there is much to discover at the Space Camp at Wacken Open Air. These include the HiveR moon rover from NEUROSPACE, a model of the Fraunhofer Earth observation satellite ERNST, and a mock-up of the ADEO deorbit sail for preventing space debris from HPS. Two-time ESA astronaut Alexander Gerst and the first German woman in space, Rabea Rogge, will land on the stage at Wacken Open Air on July 30, 2025, and August 1, respectively.

W:O:A festival co-founder and organizer Thomas Jensen on the collaboration:

“With Space Camp, we are creating a place where innovation can be experienced and shaped first-hand. This collaboration with our partners opens up completely new possibilities – we are really looking forward to the joint mission – it’s going to be loud and legendary!”

Holger Hübner, W:O:A festival co-founder and organizer, adds:

“The cooperation around Space Camp is a milestone for everyone involved. It stands for innovation, inspiration, and a genuine spirit of optimism across all boundaries – a feeling that is also reflected in the music. It’s great to be part of this ambitious project and to set new standards together.”

But there’s even more in store for metalheads between July 27 and August 2, 2025. In the exhibition tent, visitors can learn about a wide range of topics such as astronomy, light pollution, and space technology. Here, they will find stands from the BDLI, the DGLR, Fraunhofer AVIATION & SPACE, HPS, the Astronomical Society, and OHB. Interactive elements invite metalheads to try their hand at moon rovers to drive themselves, interactive games for Earth observation, and water rockets, which are being implemented by six student research groups and the Department of Space Technology (RFT) at the Technical University of Berlin (made possible by the DGLR).

In the lecture tent, Space Camp offers a top-class program of exciting lectures compiled by experts from the industry. Participants can get a taste of astronomical topics, satellite missions, and current challenges such as sustainability in space: “Heavy Metals in Space – How Gold is Formed,” “Saving the Night – How Important Darkness is for Humans, the Environment, and Astronomy,” and much more. Those who want to get involved after gaining these exciting impressions can also learn more about a career in space travel at Space Camp. Daily highlights include an Ask the Scientist or Ask the Industry format, as well as an evening Space Pub Quiz.

______

About Wacken Open Air:

Wacken Open Air is the largest heavy metal festival in the world. Starting with 800 visitors in 1990, today 85,000 fans from all over the world make the pilgrimage to Wacken in Schleswig-Holstein every year, turning the community of 2,000 souls into the center of the festival scene for several days. The organizing company, WOA Festival GmbH, has a broad network at its disposal, including band management, the Wacken Foundation, tour booking, music publishing, travel & stay, merchandising distribution, and ticketing. In cooperation with partners, this results in creative solutions and ideas that revolutionize the festival experience, enable technical innovations, and produce extraordinary event concepts. Wacken Open Air 2025 will take place from July 30 to August 2, 2025.

Successful delivery of ADEO deorbit modules to ISISPACE (NL)

July 2025

HPS, one of the industrial pioneers worldwide in the development of sustainable use of space as a resource, is now the international gold standard in deorbit technology with its ADEO t dragsail product family for all satellite classes on LEO orbits. Satellite manufacturers and operators from the EU and Asia, Australia and America use an ADEO to reliably dispose of their spacecraft within the prescribed time window of a maximum of five years after the end of operation.

The most recent example: ISISPACE, Dutch satellite system integrator and space infrastructure provider, offers innovative turnkey solutions for space missions worldwide. Founded in Delft (NL) in 2006, the company specializes in the design, development, production, testing, launch and operation of small satellite platforms, both for individual missions and for constellations. The first ADEO for an ISISPACE satellite, an ADEO-Nx class module (only 745 gr., integrable into cubesat rails, TRL9-based, short delivery time), was delivered by the HPS project team at the end of June. Yesterday, July 1, 2025, the team personally handed over the CleanGreen Certificate on site in Delft to ISISPACE coinciding with the opening of the “Symposium on Space Sailing”

HPS CEO Ernst K. Pfeiffer hopes to celebrate the “possible start of a great collaboration with one of the most prominent and successful small satellite specialists in Europe”.

ISISPACE’s vertically integrated approach has been proven in more than 50 missions carried out in a wide range of solutions and applications, including Earth observation, IOD/IOV and many others. ISISPACE is headquartered in the Netherlands and employs around 120 people from more than 30 countries.

ADEO shines at the “International Symposium on Space Sailing” 2025!

July 2025

This week, at the “7th ISSS” in Delft (NL), HPS is proud to represent Europe’s leading deorbit solution: ADEO – the dragsail for a sustainable orbit.

With the presentation by our project manager Dorottya Milankovich on Day 1, June 30th, we’re showcasing:

HPS CEO on site: “We are proud to be part of this very specialised space sailing family, ranging from solar sail developers to dragsail suppliers, from radiation scientists to sailing simulation experts.”

In total 82 participants from all over the world listened on site and via online, from USA to Philippines, from NASA to TU Delft.

This Symposium proved:

ADEO is not just a product – HPS is one of the world market leaders for deorbit dragsail modules.

Let’s sail toward a cleaner orbit!

#ADEO #Dragsail #ZeroDebris #CleanSpace #SpaceDebris #ISSS2025 #SpaceSustainability #HPS #SpaceTech #Delft #TUDelft #LEO #SpaceSailing #ESA #SatelliteDeorbiting #Deployables #SolarSailing

Inspection of the HPtex-Mesh for ESA’s Next-Gen Earth Observation Satellite Successfully Completed

June 2025

After months of precision manufacturing at HPtex GmbH, a specialist in space-grade textiles based in Upper Franconia, Germany, a major milestone was reached on June 24, 2025, for the European space mission CIMR (Copernicus Imaging Microwave Radiometer). A large-scale inspection of the mission’s deployable antenna mesh took place in the newly commissioned cleanroom assembly hall at HPS headquarters in southern Munich.

At the heart of the event: the newly developed Universal Space Mesh USM TUCH 32 – an ultra-fine metallic mesh tailored specifically for CIMR’s demanding Ka-band requirements. Available in two variants (20 µm and 25 µm wire diameters), this mesh features E32 needle fineness (32 needles per inch), an exceptionally low mass of approximately 40 g/m², and dimensions of 10.2 x 9.5 meters – making it one of the largest high-performance space meshes of its kind worldwide. The individual mesh stripes were sewn by HPtex with its reengineered sewing machine in a now fully automated and touchless sewing process. Thanks to the large knitting width (over 4 m) of the in-house high-performance knitting machines only two seams have been necessary to assembly this large mesh.

The mesh itself is woven using high-purity wire from LUMA WIRE TEC in Sweden, a long-standing partner of HPS and HPtex.

The inspection was attended by a top-tier delegation, including representatives from:

This milestone marks the culmination of four years of dedicated development under the CIMR program, building on six prior years of preparatory research and prototyping. Over the course of the project, hundreds of mechanical tension tests were conducted—primarily using HPS’s proprietary testing setup, which has been steadily refined over the years. In parallel, hundreds of RF tests were carried out, culminating at ESA/ESTEC, using their cutting-edge, high-precision RF characterization facility, to fine-tune the mesh’s electromagnetic properties. Cyril Mangenot, former RF specialist at ESA/ESTEC and one of the earliest supporters of a European LDRS solution on the agency side, supported the mesh development for HPS with all his experience.

The next step: mating the mesh with the Engineering Qualification Model (EQM) of the cable network provided by LSS. CIMR is currently in Phase C/D, with the Critical Design Review (CDR) scheduled for the first half of 2026.

This achievement exemplifies the strength of European collaboration in space technology. From materials science to RF performance, every aspect of this “dream team” effort—including ESA, TAS-IT, HPS, HPtex, LSS, and others—has contributed to an outstanding result.

HPtex is now the central European source for supplying high-performance space meshes to customers across the globe – from the Americas to Asia – and demonstrates once again that world-class aerospace innovation is alive and thriving in Bavaria.

Ernst K. Pfeiffer: Summary of the Zero Debris Symposium and Workshop

June 2025

Great: the Zero-Debris Symposium and Workshop on the Zero-Debris Booklet brought a full house to ESA’s European Space Operation Center from June 10 to 12. The program covered all relevant aspects of the topic with slots for exchanging experiences on developments over the last 12 months, panel discussions such as “Zero Debris Progress & Challenges” and presentations such as the one by HPS CEO Ernst K. Pfeiffer on “How we work with the Zero Debris Booklet”. HPS High Performance Space Structure Systems GmbH is one of the central suppliers in this “clean space” sector – but not only that: it is also one of the driving industrial forces when it comes to making space travel sustainable. To this end, the company has been investing heavily in corresponding technologies for over ten years and today covers the demand for towing sail modules (ADEO), is working on deployable membranes for the in-situ measurement of small debris (SAILOR) and has recently developed non-reflective films (ProFilm) for “dark skies”. At the end of the event, Pfeiffer summarized his summary in the following positions:

Pfeiffer particularly emphasized the positive spirit of optimism of all participants, which was carried and spread by the space giants such as TAS and OHB, the midcaps such as GMV or FEV etamax, as well as NewSpace companies such as D-Orbit, RIVADA, VYOMA, Astroscale, Clearspace, investors, lawyers, institutes, EIC and national space agencies. Special thanks went to the organizers from ESA’s Space Safety Department, in particular Quentin Verspieren, Sacha Bressollette and Calum Turner.

HPS prominently present at ESA’s Zero Debris Week

June 2025

From 10 to 12 June 2025, everything at ESA’s European Space Operations Center in Darmstadt will be dominated by the highly ambitious “Zero Debris Program” of Europe’s space agency. The days are divided into two large action chapters: from June 10-11 at noon, the Zero Debris Future Symposium will focus in particular on high-level discussions of non-technical aspects, such as the future direction of the Zero Debris Initiative and its community, as well as commercial and political challenges in connection with orbital debris. Day two, June 11-12 at noon, will be dedicated to another working session on the Zero Debris Technical Booklet. Among other things, the technical leaders who will oversee the next edition of the booklet will be elected on this occasion. The participating organizations will also discuss how they have used the booklet so far, how the work on the booklet should be regulated and organized, and how the technologies listed in the booklet can be implemented.

The Zero Debris Technical Booklet published on January 15, 2025 lists technologies that ESA believes will contribute to achieving the goal of zero debris by 2030. The booklet is essentially a technical zero debris “to-do list”. The aim is to minimize the release of new debris and reduce its impact on people, infrastructure and the Earth’s environment.

Developed by a team of engineers, operators, lawyers, scientists and policy experts from a wide range of institutions in the Zero Debris community, the booklet identifies six key technology objectives that are essential to achieving Zero Debris goals:

ESA itself is focusing its efforts on the development of debris-resistant materials and technologies, the design of satellites that can be easily removed from orbit and do not burn up on re-entry into the atmosphere, and finally the development of standardized interfaces for efficient removal in the event of a malfunction.

Beyond the satellite itself, the focus is also on new systems to remove all components of the launch vehicle from orbit. Another source of debris are small particles released by certain types of fuel and pyrotechnics in orbit during deployment. Alternatives are to be developed for this. The distribution of space debris around the Earth highlights the importance of collision avoidance measures. Once the satellites are in operation, much can be gained by optimizing collision avoidance processes and space traffic management. A key element is improving tracking capabilities for smaller, currently untrackable debris objects to refine risk assessment.

Operational practices can also be optimized, supported by new technologies to improve communication infrastructure and spacecraft health monitoring. At the end of a mission, the deorbit and re-entry process (for LEO and MEO satellites) and the impact on the environment need to be considered. Active debris removal services are required in orbit, as well as reducing the environmental impact of debris re-entry on the ocean and atmosphere, which will begin with further research.

Participation in ESA’s Zero Debris Initiative is a top priority for HPS – and accordingly, HPS CEO Ernst K. Pfeiffer will take part in the central program items on both days in Darmstadt. HPS’s commitment goes far beyond academic aspects, as the company has already made a remarkable contribution to avoiding space debris with its ADEO Deorbit Module product family by rapidly removing disused satellites from orbit; in addition, it is already on the threshold of Phase B with initial developments for a detector for previously undetectable particles from 0.1 to 10 mm in size called SAILOR.

The HPS boss doesn’t mince his words when it comes to emphasizing the importance of the ESA initiative: “The Zero-Debris Initiative is a start, but we are still a long way to our goal. We still have to reach an important milestone, and that is directly in the minds of the target groups: In parts of the space community, the debris issue is still seen as merely a green nice-to-have topic. This is absolutely wrong: it is an issue of great commercial interest and value, because if the littering of orbits continues at this rate, economically viable activities in space will soon be history – and that so before they have really taken off.”

HPS puts ADEO know-how at the service of ESA´s Hungarian Prime C3S

May 2025

It seems to be a basic law of nature: Wherever and however humans are active, they end up producing large quantities of waste. To suppress the problem, many terrestrial areas, the oceans and, in recent decades, outer space itself have become dumping grounds. However, the latter in particular is now threatening to take radical revenge, as flying debris from previous space missions is increasingly becoming a threat to all other activities, especially in the most frequented orbits between 200 and 1200 kilometers.

While large debris such as burnt-out rocket stages are the easiest to detect and can be avoided by new guests in orbit, it is the small projectiles, flying with 5-10 km/s orbital speed, which have often shrunk below millimeter size as a result of previous fragmentations, that pose the greatest threats. Even one millimeter-sized debris impact can render a satellite inoperable. Emerging their threat further, their flux increases significantly as their size decreases, with the consequence that the much more frequent impacts of debris of this size can pose a far greater risk to space operations than the more dramatic catastrophic incidents.

However, only larger debris can be observed and tracked from the ground – but not in the critical range of 0.1 to 50 mm. Therefore, measurements in situ, i.e. directly in orbit, are urgently needed to make it possible to describe the Earth’s flying garbage dump with sufficient reliability in the first place. After critically weighing up the alternatives, ESA has turned its attention to a possible large-area detector based on the successful ADEO deorbit sails from HPS. If the sail membranes are now equipped with acoustic sensors and cameras on board, it will be possible to measure the dust flow in the required size range. The name of the project: SAILOR – Sail Array for Impact Logging in Orbit.

The spacecraft consists of two large detector surfaces 100 cm apart. The two sails have an exposed surface area of 25 m2; in the ADEO program, they are the main actors of the large dragsail versions under the name ADEO-L. The membranes are around 10 μm thick and are held in position by extendable cross booms. The booms are stowed together with the sail membranes during launch and deployed in orbit. The deployment module in which booms and sails are integrated, consists of a deploying mechanism with a motor that pushes the boom arms outwards. A system of multiple cameras is mounted to a separate boom to document the holes created on the inner surface of both sail membranes. Acoustic sensors are attached to the sails to detect an impact in real time. The interaction of SAILOR’s technical equipment will ultimately allow the density, speed and trajectory of the small debris to be determined.

The ambitious ESA project SAILOR is currently in the transition from Phase A to Phase B1, which will also include the construction of breadboard models of the spacecraft and its electronics as well as the associated test programs. It also involves these steps:

Overall, the specifications of the project in this phase should lead to a positive decision at the ESA Ministerial Council meeting in Bremen in November 2025 on the continuation of a three-year mission at an altitude of 850 km to be launched in 2031/2032. The industrial team proposes a small precursor CubeSat mission, called OPTIMIST after this type of sailboat, to test the sensor technology using an approx. 10 m2 membrane as early as 2027/2028 as risk mitigation for the full-scale mission.

The industrial structure behind SAILOR also stands for this. This is because C3S, a leading Hungarian aerospace company, is acting as prime contractor for an ESA project of this kind for the first time, drawing on the expertise of ADEO inventor HPS GmbH as a subcontractor for the deployable membrane subsystem. C3S is also planning work shares for HPS in Romania. HPS CEO Ernst K. Pfeiffer: “The great enthusiasm with which we have taken on our role in this project rests on three pillars: firstly, it is existentially important for the space industry as a whole; secondly, it is an opportunity for us as HPS to impressively demonstrate the versatility of the ADEO technology from our company; and thirdly, we consider it eminently important in Europe that the industrial talents of Hungary and Romania are finally brought to light in an appropriate way, and that in a joint mission. We at HPS are delighted to be working under the project management of C3S.”

CIMR-LDRS: The lighthouse project for non-dependence in European space travel enters the production phase of the qualification model (EQM) as planned

April 2025

Long before an unspeakable bloodbath sealed the end of peaceful life in Eastern Europe in 2022, the demand for technological “non-dependence” had already conquered a top position among the strategic priorities in German and European space travel. The focus was particularly on large reflector antennas that could be deployed in space, suitable for missions of all kinds.

The history of this German technology for Europe began more than a decade ago with SCALABE, a technology development funded by ESA, and SMERALDA (SME’s Radar and Large Deployable Antenna), a study funded by the German Space Agency with significant participation by antenna specialist HPS GmbH. Through further technical chapters of successful concretization of the goal with significant support from ESA and the EU, the Munich-based company finally led a consortium of mostly medium-sized partners from eight countries to the spectacular win of the 115 million euro contract from Prime`sThalesAlenia Space (TAS) for “CIMR LDRS” (Large Deployable Reflector Subsystem) in 2020: the world’s largest rotating deployable reflector antenna construction for the EU’s Copernicus Imaging Microwave Radiometer (CIMR) lighthouse project for observing land, ice and oceans, particularly the Arctic, from space under the management of the European Space Agency (ESA). The LDR subsystem consists of a reflector, arm, deconvolution electronics, cabling, various hold-down mechanisms and thermal hardware.

After a long design phase and intensive iteration with the direct customer TAS in Rome and the end customer ESA, the go-ahead was given in phase C/D with the completion of the first so-called “Manufacturing Readiness Review” for the construction and testing of a qualification model (Engineering Qualification Model, EQM). In these days of spring 2025, HPS has now finally entered the intensive phase of manufacturing the EQM.

Challenges on the way to new shores

The technical challenges were and are immense, as the goal is nothing less than a deployable reflector construct for high frequencies (Ka-band) with a diameter of eight meters on an equally deployable eight-meter-long arm that rotates around its own axis eight times per minute in orbit. This results in extreme requirements such as an RMS (Root Mean Square) value for the surface accuracy, which must be much smaller than 1/10 mm over the entire 50 m² reflector surface, or a maximum permissible deviation of the 8 m distant arm tip of just 10 mm from the nominal value, including vibrations, centrifugal force and thermal deformations.

The challenges of managing the various aspects of the project were and are no less demanding. The program management of the CIMR team from ESA and TAS has played a prominent role from the outset, while HPS GmbH, known for its heritage in institutional, military and commercial antenna construction – in addition to its own development work at arm and subsystem level – is responsible for managing the consortium of around a dozen SMEs, including such outstanding innovation drivers as Munich-based LSS GmbH for the deployable reflector assembly (DRA), based on a highly successful, long-standing development partnership. The lightweight carbon struts for the DRA come from the former Portuguese HPS subsidiary and now FHP, INVENT GmbH contributes the carbon fiber-reinforced tubes for the 8-meter deployable support arm (DAA), NanoSpace Switzerland develops and produces the high-precision yet stable, motor-driven joints of the arm, HPS Romania and INEGI Portugal the constructions for ground tests and transports (“MGSE”). In addition, HPS is responsible for providing the central element for the deployable reflector: the measurably best Ka-band MESH from HPtex that is available to buy in a 9m x 9m size – and, as a “made in Germany” product, transforms European non-dependence from vision to reality. Until then, a MESH in such dimensions had only been available in American production. Originally planned as an essential element of the German-European supply chain for CIMR, the joint venture HPTex GmbH (JV of Iprotex GmbH & Co. KG and HPS GmbH), founded in 2020, now sells its mesh products worldwide, especially in Asian and continental American countries. The EQM mesh for CIMR recently came out of HPtex production.

The most important components (DAA and DRA) will be ready by the end of the year, and the series of tests will begin early in 2026.

“If you want to be ahead, you shouldn’t be afraid of the unknown” (Ernst K. Pfeiffer)

When CIMR sets off on its mission in 2029 on board a Vega C in a sun-synchronous orbit to observe ice sheets and snow, among other things, from dawn to dusk, Europe will not only benefit from the knowledge gained from the project, but also from the certainty of having mastered the step towards technological LDRS independence. LDRS are also products for a range of military applications that can contribute to an increased defense capability, especially in these years. HPS CEO Ernst K. Pfeiffer sees this as a milestone that goes far beyond the immediate success of the project: “This space project is clear proof that the mentality of all those involved in the project – both industry and institutions – is completely different to the risk aversion that the public normally attributes to Germany in particular, and to some extent also to ESA. Not being afraid of the unknown is the first key to success. Way up front is where it´s getting dark. Especially in space. But not only there.”

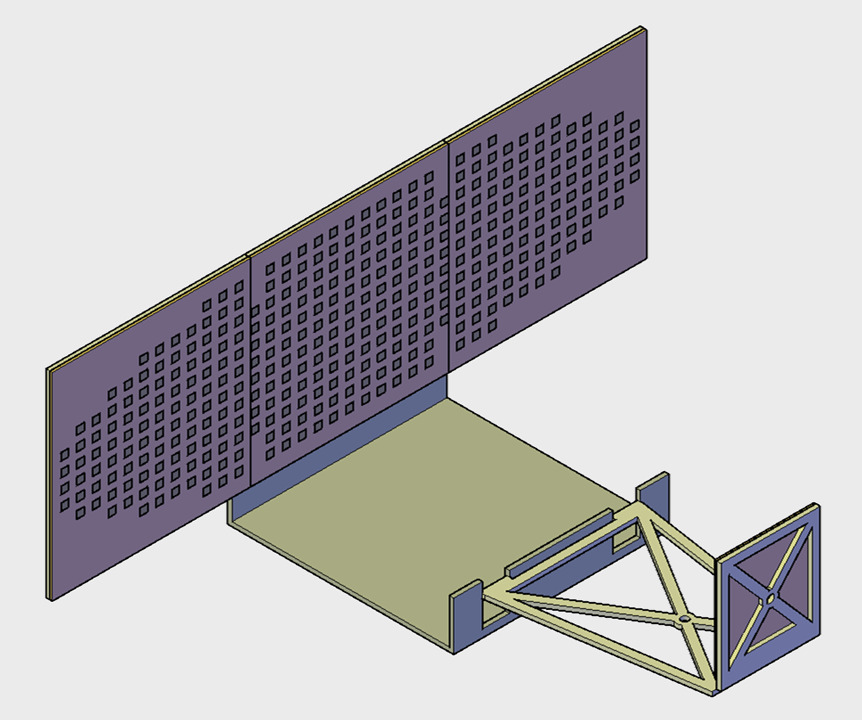

Pushing the limits of what’s possible in CubeSat technology – for science, for Earth, for the future

April 2025

We are thrilled to announce that HPS GmbH has been awarded a new Technology Activity by the European Space Agency (ESA)! The contract signature has been taken place on 08.04.2025.

In this groundbreaking GSTP-project, we will develop a cutting-edge CubeSat deployable ArrayAntenna in collaboration with our esteemed partners at Fraunhofer-Gesellschaft (IIS, Germany). This innovative technology, known as MANT (Miniaturized Deployable Antenna for Small and Nanosatellites), will reach TRL6 by the end of the project, marking a significant advancement for the capabilities of small and nanosatellites focussed to civil Earth Observation applications, which always would enable also “Dual Use”. The project is fully funded with a budget of 750,000 euros and will run for two years.

We are excited to contribute to the next generation of satellite technology, advancing small satellite communication with more efficient, compact, and powerful solutions. Stay tuned for updates such as for detailed geometries (in stowed configuration: less than 1U), frequencies and interfaces, as we never stop working towards transforming space technology!

Next Milestone: Requirements Review by end of May.

Cubesat-UDAN: CDR successfully completed – a major milestone for Europe’s disruptive antenna technology

April 2025

NewSpace relies primarily on small satellites. However, their efficiency is primarily based on antenna performance: the smaller the satellite, the lower the antenna performance and the more expensive it is to technically compensate for this on the ground. The solution from HPS Munich and its Romanian subsidiary in Bucharest: an antenna that can be deployed outside the satellite in the form of a 50 cm high conical quadruple helix and 90 cm diameter ground plane with the additional advantage that it can be scaled to even lower or higher frequencies than the planned bandwidth of between 410 and 460 Mhz but always keeping a gain above 10 dBi. Stowed together for the launch phase, the antenna package is only 10x10x15 cm in size.

ESA was convinced and awarded the development contract in 2018 within its ARTES program to the German specialist for deployable antennas, HPS GmbH in Munich and its Romanian subsidiary HPS S.R.L., Bucharest. In the meantime, the German Space Agency at DLR has provided further ARTES funding to maximize efficient development.

We are delighted that the next major milestone has also been passed with flying colors: the punctual completion of the CDR phase in March 2025. This will now be followed by the production of the engineering model in the second and third quarters and then the test campaign; the contract ends in the fourth quarter of 2025. HPS CEO Ernst K. Pfeiffer comments “With this project completion, HPS will raise UDAN’s maturity level to TRL 6 and then finally to TRL 9 with a planned in-orbit demonstration (IOD). This means nothing less than clear the way for the latest generation of antenna technology on the commercial NewSpace market!”

A full success: the “Space Day” at HPS

March 2025

On March 28, 2025, HPS in Munich opened its doors to space enthusiasts and those who might want to become one – and it was a great success! We welcomed numerous guests who took part in our guided tours, presentations, Q&A sessions and workshops with great interest. We were particularly pleased about the visit of Ministerial Director Dr. Markus Wittmann and MRin Anne Köster from the Bavarian State Ministry of Economic Affairs, who came to get a personal impression of our work in Bavaria (Munich and Münchberg in Upper Franconia).

The entire day was characterized by innovation, thirst for knowledge and enthusiasm for space travel. Our guests were given exclusive insights into our products, expertise, processes, test laboratories and clean rooms. Our experts gave exciting introductions to the world of e.g. satellite communication, earth observation and manned space flight and their space technologies. Our CEO, Dr.-Ing. Ernst K. Pfeiffer, gave a presentation on “Why space travel?” in the early afternoon and in the evening, also providing insights into the latest news in global space travel.

The crowds were large and the curiosity of our visitors was overwhelming – every guided tour and every lecture was followed with great interest.

The consistently positive feedback was particularly pleasing: many participants praised the opportunity to experience space travel up close and learn more about HPS technologies. This great response reinforces our goal of sharing not only our fascination for space but also its necessity for Germany and Europe.

With this success, we are very optimistic about the future and hope that after a few years there will be another nationwide “Space Day” to spread the enthusiasm for space travel together with you!

Many thanks to everyone who took part and made this day possible! See you soon!

State-of-the-art antenna serving one of the most ambitious missions ever

March 2025

“We are opening up a treasure trove of information for scientists,” said Esa Science Director Carole Mundell. Clotilde Laigle from the “Euclid” consortium described the newly won probe of EUCLID as a “gold mine of data”.

HPS, leading provider of advanced antenna- and reflector-technologies, applauds the European Space Agency ESA to this remarkable progress in the project EUCLID (European Space Agency’s Cosmic Vision: Euclid) which aims to unravel the mysteries of the dark universe and gain insights into the nature of dark matter and dark energy.

EUCLID´s Antenna Reflector Assembly (ARA)” developed by HPS under TAS-contract represents a significant advancement in space communication technology. Its innovative design and advanced features make it an ideal choice for the mission, enabling high-speed data transmission and reception from the spacecraft to Earth and back.

“We are thrilled to contribute significantly to the Euclid mission,” says Ernst K. Pfeiffer, CEO of HPS. “Our cutting-edge technology facilitates seamless communication between the spacecraft and ground stations and allows scientists to unlock and reveal to us on Earth all those mysteries of the dark universe.”

Picture by ESA

HPS with ADEO product family: top position in NASA’s technology report extended

March 2025

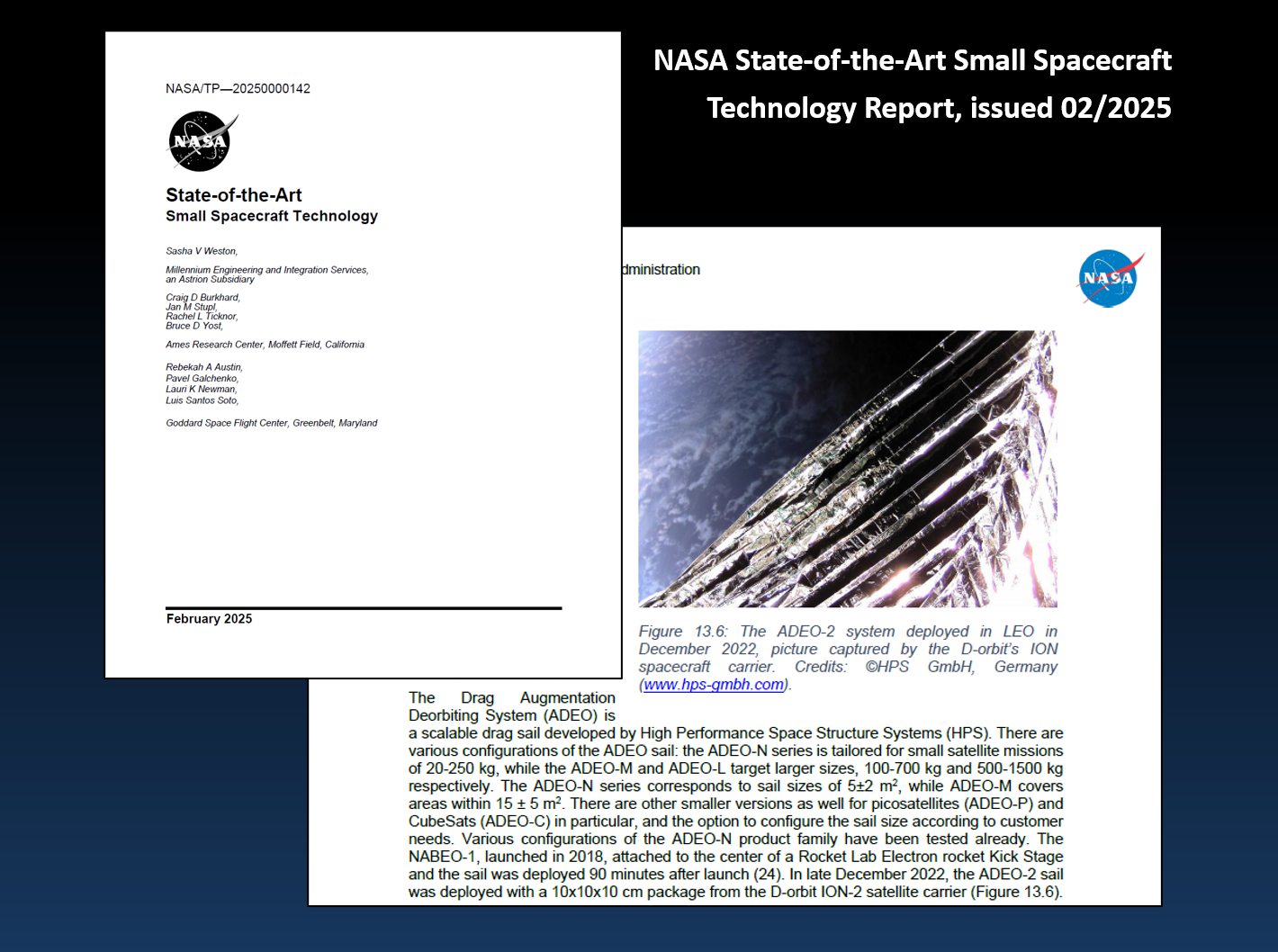

A year ago, the deorbit module from HPS took its place at the top of the podium of the most important technology achievements according to NASA. This was because ADEO already had everything that the American space agency considered crucial for success at the time: top values up to TRL9, scalability and proven flight heritage. Exactly one year later: ADEO, now supplemented in the technology report by the presentation of the bestsellers ADEO-Cube and ADEO-Pico, maintains its position both against numerous Dragsail competitors and against other passive deorbit technologies.

HPS CEO Ernst K. Pfeiffer comments: “With ADEO, we are surfing at the top of the wave worldwide that we have created ourselves with this technology over many years of R&D – often with significant co-financing by ESA and DLR plus considerable company resources. And we are actually delighted with every attempt by other companies to establish deorbit sails on the market: The bigger they make the wave, the higher our product family sails on its crest.”

ADEO – Space Heritage

January 2025

ADEO (Atmospheric Deorbit Sail Module) is the name for an entire product family of drag sails for satellites from the German space company HPS, Munich. They accelerate the disposal of satellites from space to a period of less than five years and thus fulfill the prerequisite for the satellite to receive approval for launch into space in the first place.

The sail is scalable and available in many variants from series production. ADEO-N is tailored to small satellite missions of 20-250 kg, while the ADEO-M and ADEO-L series are designed for larger missions of 100-700 kg and 500-1500 kg respectively. The ADEO-N series corresponds to a sail size of 5±2 m2, while ADEO-M covers areas of 15 ± 5 m2 and ADEO-L 25 m2 and more. However, smaller versions have also been available for a year, especially for cubesats, e.g. an ADEO-P for 1U-6U satellites (1-20 kg) and an ADEO-C for larger cubesats (5-50 kg). A total of five versions are currently available to order, all of which reliably dispose of satellites from LEO – including those from higher MEO orbits when combined with satellite’s onboard propulsion – within the required time frame. A corresponding configurator for selecting the perfectly suitable ADEO module is available for individual mission calculation (ADEO Online Configurator).

Now there is a short film about the production and testing of the product family, as well as ADEO’s heritage story:

Based on over ten years of development, HPS has successfully completed a series of missions up to “full burn” and has thus firmly established itself at the top of deorbit technologies at qualification level TRL 9.

2018: ADEO-N1 (“NABEO”) was launched on a Rocket Lab Electron rocket kick stage back in 2018, with Peter Beck himself (CEO RocketLab) even personally handling the sail. On this flight, the sail was unfurled just 90 minutes after the launch. Visual ground observations confirmed the successfully deployed sail and its performance.

2021: In June 2021, ADEO-N2 (“Show me your Wings”) was launched into space by the spacecraft carrier ION-003 of the Italian launch service provider D-Orbit, as part of SpaceX’s Transporter-2 mission. The successful deployment of the sail in December 2022 was recorded by the ION carrier’s on-board camera. The integrity of the sail after one year in orbit was confirmed, again by means of the onboard camera. On December 8, 2024, HPS received confirmation that ADEO-N2 had completed its mission with deployment of the dragsail at 506 km orbit altitude in a record time of just two years after the 210 kg satellite’s “end-of-business” with fireworks of success at 120 km orbit altitude, beating international rules and regulations by three full years.

Even NASA ranks the ADEO module from HPS as the number one automatic passive deorbit technology in view of the qualification and Flight Heritage.

ADEO is now a bestseller not only with European institutions and companies, but also in the fully commercial markets of the USA and Canada.

Highest qualification levels, proven reliability and flight heritage combined with scalability, availability and attractive pricing make the ADEO product family a highly visible beacon in the global field of deorbit systems for all satellites that must comply with the new 5-year deorbit requirement to obtain launch authorization.

Click here for the latest clip about ADEO

————————-

Video: © HPS GmbH, Munich, Germany, www.hps-gmbh.com

Production: Daniela Creutz, www.bluecirceproductions.com

————————-

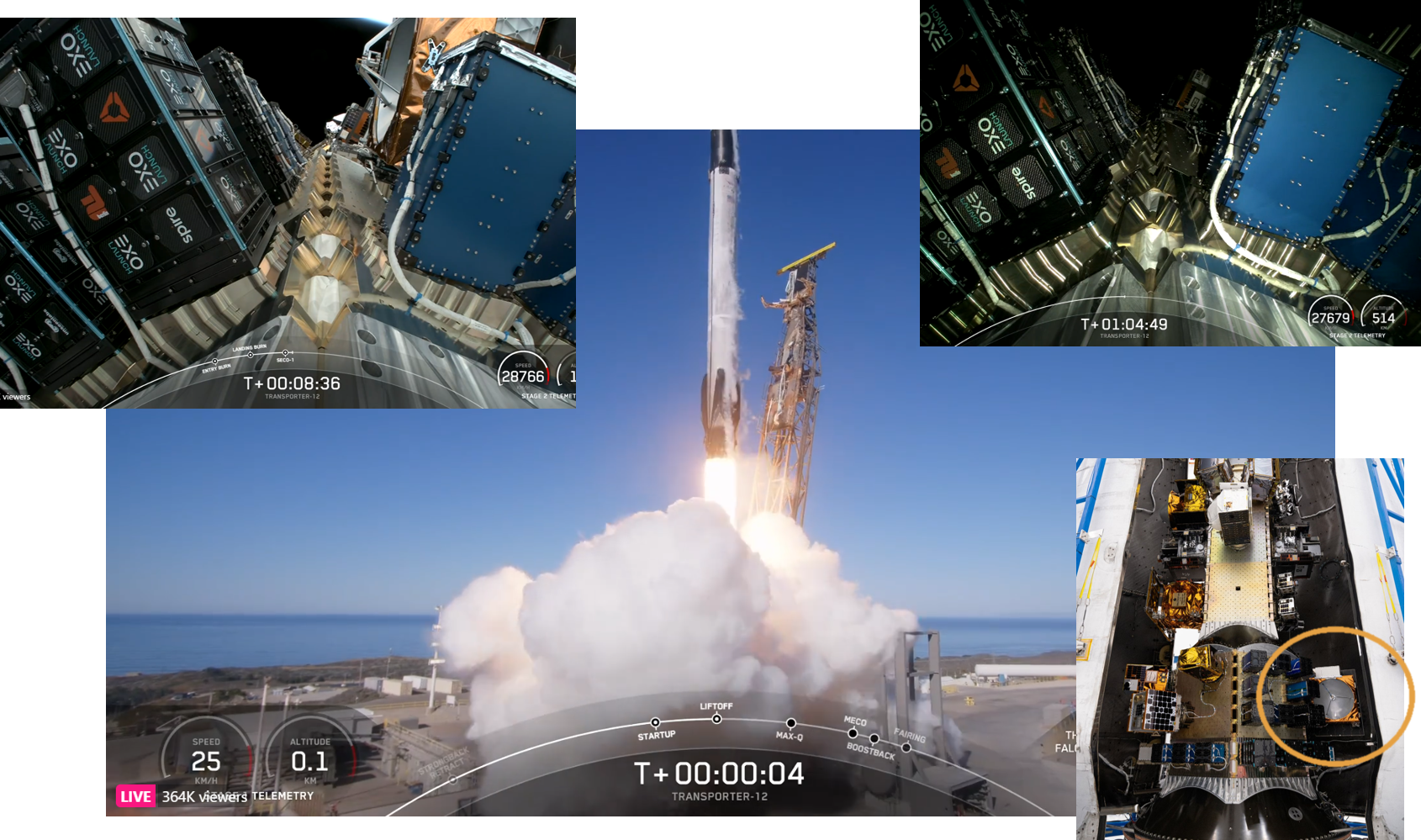

Two HPS contributions on board the Transporter 12 mission on January 14, 2025

January 2025

Even HPS has never done this before: two of the company’s products are on their way to a sun-synchronous orbit on a Falcon 9 mission. This has been made possible by the rideshare- version of the SpaceX rocket named “Transporter 12”.

On the one hand, the contributions from HPS relate to the highly innovative BANT-1 reflector antenna for Reflex Aerospace’s premiere satellite – see also the HPS news item “HPS congratulates Reflex Aerospace” from today, January 14.

On the other hand, a contribution from HPS itself is the premiere. For the first time, HPS Germany and HPS Romania have jointly prepared a flight hardware with the MLI insulation of the central radiator in such a way that the thermo-optical properties of the satellite are maintained even under the most adverse conditions in space.

The satellite is Sky Bee-1 and part of a thermal infrared constellation HiVE that provides highly accurate yet cost-effective daily temperature data of the world’s land surfaces with a resolution of 30 meters for the benefit of agriculture, urban and industrial environments. The HPS teams of both European countries warmly congratulate their client OHB on the launch success. The first flight model SkyBee-1 is being developed under the InCubed Programme, co-funded by the European Space Agency.

Space premiere also for the innovative BANT-1 reflector antenna from HPS

January 2025

On January 14, 2025, “SIGI”, the first satellite from the NextSpace company Reflex Aerospace, Berlin/Munich, was launched on board a Falcon 9 – Rideshare Mission Transporter-12. “NextSpace” is the term legally reserved for exclusive use by Reflex to describe the new speed in the development, production and provision of space technology, coupled with innovative versatility as a leitmotif for the performance of the product.

To a large extent, this also applied to an essential element of the satellite not manufactured by Reflex: the core broadband reflector antenna developed by HPS from the medium-sized space technology company HPS GmbH (Munich, Germany) with a cavity-backed spiral antenna as an axial feed for a wide bandwidth and considerable gain – and all that from order to delivery in just 12 months.

HPS congratulates Reflex Aerospace on the first launch of one of its products and looks forward to working with them on further NextSpace challenges in space.

Pictures by SpaceX